Sheet metal is the form of metal that has been converted into a thin, flat sheet. Sheets, produced from various metals such as steel, aluminum, and copper, are widely used in industrial and commercial applications. Sheet metal is known for its high durability and flexibility, making it a fundamental material in the construction, automotive, home appliances, and many other industries.

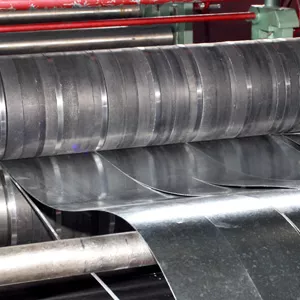

The production process of sheet metal begins with rolling the metal and reducing it to specific thicknesses. This process ensures the metal has a homogeneous structure and improves its mechanical properties. Sheet metals can be produced in various thicknesses and sizes, allowing customization for different projects and applications. Thanks to their durability, flexibility, and versatile usage possibilities, sheet metals have become an indispensable part of modern industry.

What is Sheet Metal?

Sheet metal is a thin, flat form of metal widely used in various industrial applications. Sheet metals, which can be produced from metals like steel, aluminum, and copper, are fundamental materials in construction, automotive, home appliances, and many other sectors due to their durability and versatile usage areas.

In the production of sheet metals, the metal is rolled and reduced to specific thicknesses. This process ensures the material has a homogeneous structure and improves its mechanical properties. Sheet metals can be produced in different thicknesses and sizes, allowing them to be customized for use in various projects.

How is Sheet Cutting Done?

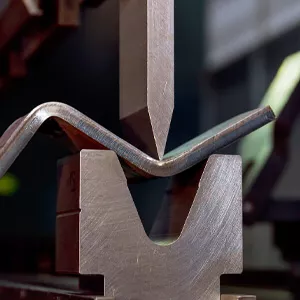

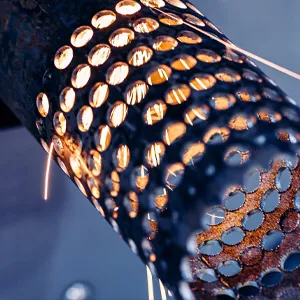

Sheet cutting is the process of cutting metal sheets into specific dimensions and shapes. This process can be performed using different methods such as laser cutting, plasma cutting, water jet cutting, and mechanical cutting. Laser cutting is preferred for jobs requiring high precision and quality, while plasma cutting is ideal for quickly and efficiently cutting thicker metals.

Water jet cutting is a cutting method that does not damage the metal and does not generate high heat. As a result, the material's structure remains intact during cutting, achieving high-quality results. Mechanical cutting is commonly used in large-scale jobs and mass production processes.

Benefits Provided by Deha Metal to Companies

As Deha Metal, we offer various advantages to our clients with our sheet cutting services. Thanks to our modern cutting technologies, we can cut with the desired dimensions and high precision. Thus, we provide solutions that best meet your needs, maintaining high-quality standards at every stage of your projects.

By responding to customer demands promptly, we ensure that projects are completed on time. We develop customized solutions and unique approaches for each project. With our competitive pricing policy, we provide cost advantages to our clients, enabling you to receive quality service without exceeding your project budget.

Why is Sheet Metal in High Demand?

Sheet metals are in high demand in industrial and commercial applications due to their durability, flexibility, and versatile usage. Offering high strength and longevity, sheet metals are resistant to different climate conditions and challenging work environments. These attributes highlight them as indispensable materials in industries like construction and automotive.

The ease of processing is also one of the reasons sheet metals are preferred. They can be shaped into desired forms using various cutting and shaping methods. The low production and processing costs make sheet metals an economic solution. These features broaden the usage of sheet metals across various industries.

Advantages of Metal Sheet Cutting

Metal sheet cutting offers numerous advantages. First and foremost, high-precision cutting techniques allow cutting in desired dimensions and shapes. This enables us to provide solutions that best meet your project's needs. Advanced technology methods like laser cutting allow for excellent results with minimal error margins.

Additionally, metal sheet cutting is an economical and efficient process. Modern machines capable of high-speed cutting execute large amounts of production in a short time. This ensures projects are completed on time and cost-effectively. Metal sheet cutting is also an environmentally friendly process, producing minimal waste and allowing work with recyclable materials.

Where is it Used?

Sheet metals have a wide range of applications. In the construction sector, they are commonly used as structural elements, roof, and wall coverings. In the automotive sector, they are preferred in the production of vehicle bodies, chassis, and other parts. Due to their durability and flexibility, sheet metals are cornerstone materials for these sectors.

In the home appliance sector, sheet metals play a significant role in the production of refrigerators, ovens, washing machines, and other household items. They are also used in wiring and electrical panels in the electrical-electronics industry, and in metal furniture and decorative items in the furniture sector. Thanks to their versatile usage and superior properties, sheet metals stand out as an indispensable material in many industries.