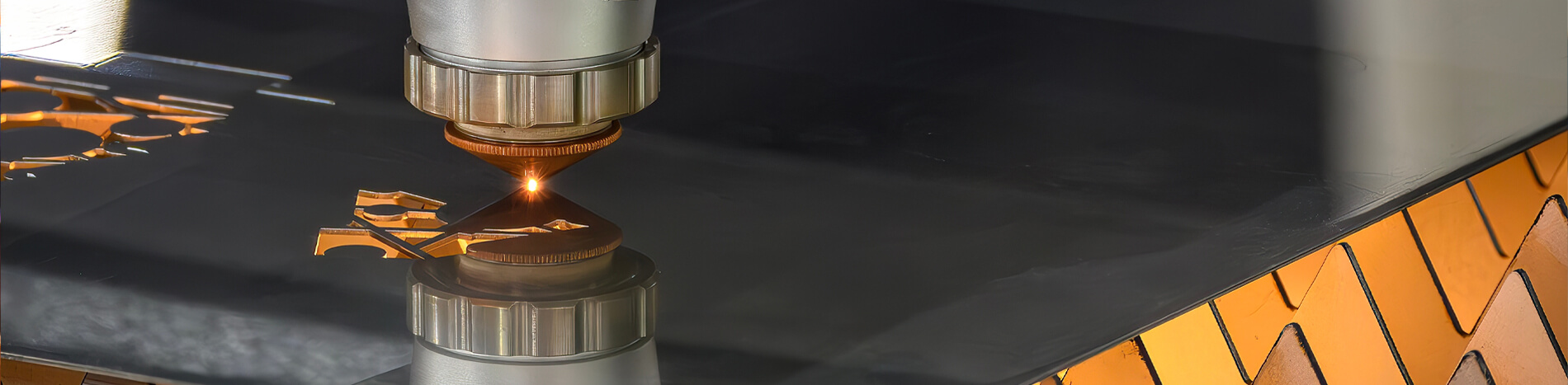

With advancing technology, precision and efficiency in industrial processes have become increasingly important. In this context, laser cutting stands out as a prominent technique. Offering precise cuts and versatility, this technology is widely used across different sectors. Laser cutting not only makes the production line more efficient but also allows for quality results.

What is Laser Cutting?

Laser cutting involves using a laser beam as a very fine and concentrated energy stream to cut or shape materials. The laser cutting machine focuses this energy beam on a specific point, melting, vaporizing, or burning the material. This technique is ideal for a variety of applications due to its precision and speed.

What Materials Can Laser Cutting Be Used On?

Laser cutting can be effectively used on various materials. Here are the main materials that can be processed with laser cutting:

Metal: Metal laser cutting is used to precisely cut metals such as stainless steel, carbon steel, and aluminum. Laser iron cutting is especially popular in industry.

Plastic: Plastic materials like plexiglass, acrylic, and PVC can be shaped using laser cutting.

Wood: Materials like MDF, plywood, and solid wood can be cut with fine details using a laser cutting machine.

Textile: Leather, felt, and fabrics can also be shaped using laser cutting.

Glass and Ceramic: Applications such as engraving or surface foaming can be performed on these materials with lasers.

What are the Advantages of Laser Cutting?

There are various advantages to laser cutting. These can be summarized as follows:

High Precision: The laser cutting machine offers micron-level precision, allowing even complex designs to be processed with fine details.

Fast Processing: Laser cutting is faster than traditional cutting methods and suitable for mass production.

Clean Cuts: This technique makes clean cuts with minimal burrs, which is a major advantage for laser cutting companies.

Reduced Material Loss: Laser cutting minimizes material wastage and reduces scraps.

Flexibility: Offers the ability to cut different materials and thicknesses.

Low Maintenance Requirement: Modern laser cutting machines stand out with low maintenance costs.

What Should Be Taken into Consideration in the Laser Cutting Process?

To achieve a successful outcome in the laser cutting process, some factors need to be considered:

Material Selection: It should be checked whether the material to be cut is suitable for laser cutting. For instance, a suitable machine should be chosen for metal laser cutting.

Correct Machine Settings: The power, focus, and speed settings of the laser cutting machine should be correctly configured.

Safety: Safety equipment should be used in the laser cutting process, and the work area should be appropriately isolated.

Maintenance and Cleaning: Laser cutting machines should be regularly cleaned, and their maintenance should be timely performed.

Experienced Personnel: Having trained personnel to conduct the cutting operations enhances both quality and safety.

In Which Industries is Laser Cutting Widely Used?

Laser cutting is widely used in various industries. The main ones are as follows:

Metal Processing: Laser iron cutting and the processing of other metal materials are common, especially in areas like automotive and machinery manufacturing.

Advertising and Signage: Shaping plexiglass and acrylic materials is frequently preferred in sign and advertising works.

Furniture: Wood laser cutting enables detailed work in furniture design.

Engineering and Prototyping: Laser cutting is widely used in engineering projects and prototype production that require high precision.

Fashion and Textile: Provides precision in cutting fabrics and leathers.

Healthcare: Used in processing medical devices and very precise medical components.

Laser cutting has become an indispensable part of modern production technologies with its various advantages and wide application area. Laser cutting companies can meet customer demands quickly and effectively thanks to this technology. Offering precise cuts, versatility, and cost-effective solutions, laser cutting is expected to find a place in more industries in the coming years.

What Machine Models are Preferred for Laser Cutting?

Laser cutting is a highly precise and effective technology used in a wide range from industrial production to crafts. When choosing between laser cutting machines, selecting a model suitable for your project's needs is crucial. Generally, CO2 laser, fiber laser, and Nd:YAG laser machines are the most commonly used models.

CO2 Laser Machines: These machines are highly used in cutting materials like wood, leather, plastic, and fabric. They provide precise and clean cuts.

Fiber Laser Machines: Ideal for harder and more durable materials. Especially preferred for metal laser cutting operations.

Nd:YAG Laser Machines: Provides precise cuts on metals and hard materials thanks to its high energy density.

Laser cutting companies often choose one or more of these machines based on project specifications. Selecting the appropriate machine for your projects helps optimize costs and ensures satisfaction with the results.

What is the Role of Gases Used in the Laser Cutting Process?

Gases used in the laser cutting process directly impact the cutting quality and the material's workability. Nitrogen, oxygen, and argon gases are the most commonly used. Each of these gases plays a different role:

Nitrogen: Provides a clean cut on metals like stainless steel and aluminum. Prevents burrs during cutting.

Oxygen: Used in cutting materials like carbon steel. Provides faster cutting with high energy.

Argon: Provides protection during welding or cutting. Preferred in special applications.

In using a laser cutting machine, the choice of gas is a critical factor in determining the quality of outputs. Choosing the right gas in metal laser cutting applications enhances precision and reduces cutting costs.

What Materials Can a Laser Cutting Machine Cut?

Laser cutting machines can be used to cut a variety of materials. These machines offer a wide range of applications depending on the thickness and type of material:

Metal: Stainless steel, carbon steel, aluminum, and copper are commonly used in laser iron cutting processes.

Wood: Suitable for cutting wooden materials requiring fine craftsmanship in furniture and decoration projects.

Plastic: Precise shaping of plastic materials like acrylic and PVC can be achieved.

Fabric: Often preferred for leather and textile materials as well.

This wide material compatibility allows laser cutting companies to effectively serve diverse projects.

What Are the Advantages of Using a Laser Cutting Machine?

The numerous advantages of using a laser cutting machine have made this technology indispensable for many industries. Some notable advantages include:

Precision and Accuracy: Laser cutting offers micron-level precision, allowing even complex designs to be easily shaped.

High Speed: Faster than traditional methods, facilitating quick project completion.

Minimizing Material Waste: Material loss is minimized during the cutting process.

Flexibility: Can be used on various materials from wood to metal.

Low Maintenance and Operating Cost: The long-lasting and efficient nature of laser cutting machines provides a cost advantage.

These advantages of laser cutting technology make it a preferred choice for both small companies and large industrial firms.

What Types of Projects Can Be Done with a Laser Cutting Machine?

The projects that can be done with laser cutting machines are limitless, depending on your creativity and needs. Some common projects include:

Furniture Designs: Wood and metal laser cutting technology is used to precisely shape furniture pieces.

Industrial Parts: Machine spare parts or metal pieces requiring special designs can be easily produced with laser iron cutting machines.

Advertising and Signage: Signage and advertising materials can be created using acrylic, wood, and metal.

Art and Crafts: Decorative objects, sculptures, and templates can be made.

Laser cutting companies stand out in these types of projects with specialized equipment and professional teams. Providing solutions tailored to each project's needs, these companies lead the way with innovative technologies in the sector.

Laser cutting technology, with its speed and precision, is an ideal option for both individual and industrial projects. When selecting a laser cutting machine, it's important to consider your project's needs and the properties of the materials you are using. With the correct machine and gas usage, you can gain a cost advantage and complete your projects professionally. With the wide range of services offered by laser cutting companies, realizing your dream project becomes much easier.

TR

TR