Today, especially in the construction sector, the search for durable and economical solutions highlights steel mesh. Noted for its features such as high strength, flexibility, and long lifespan, steel mesh has a wide range of applications.

What is Steel Mesh?

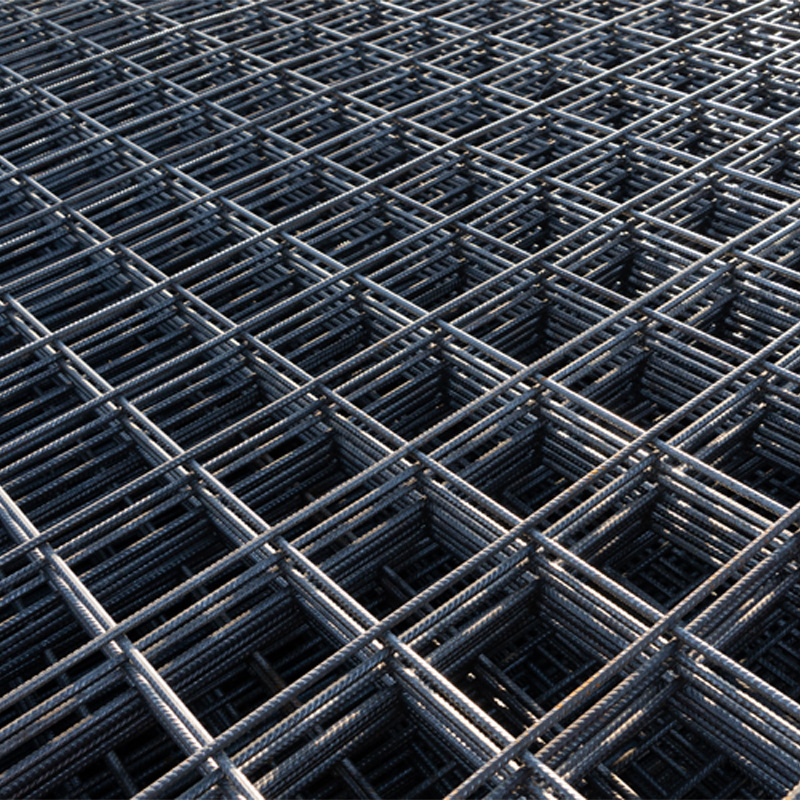

Steel mesh is a special reinforcement material used in reinforced concrete structures. Obtained by combining and welding steel bars in a specific arrangement, steel mesh mostly features rectangular or square openings. This structure enhances the strength of concrete and ensures longer durability in structures. Steel mesh is commonly used for reinforced concrete floors, walls, and prefabricated elements.

The main reasons for the popularity of steel mesh include the fast production process and low cost. Steel mesh manufacturers use modern technologies in production to provide standard-compliant and durable products.

Steel Mesh Usage Areas

Steel mesh finds a wide range of applications in various industries. The main ones are as follows:

- Reinforced Concrete Floors: Steel mesh is used in reinforced concrete floors to provide high strength and durability. This makes the floors resistant to heavy loads and intense traffic.

- Tunnels and Bridges: The use of steel mesh is common in infrastructure projects such as tunnels and bridges. Flexibility and durability are important in these structures.

- Prefabricated Elements: Steel mesh is used in the production of prefabricated elements, enhancing their strength. Prefabricated structures, which can be easily assembled, become much more durable.

- Industrial Structures: In industrial structures like factories and warehouses, steel mesh is used in shaping and supporting reinforced concrete floors.

- Floor and Wall Reinforcement: Steel mesh is preferred in floor and wall reinforcement processes in multi-story buildings. These structures become more resistant to natural disasters and environmental conditions.

- Agricultural Structures: The use of steel mesh is prominent in agricultural structures such as livestock shelters and greenhouses. Durable structures provide continuity for many years thanks to steel mesh.

What Are the Technical Specifications of Steel Mesh?

The technical specifications of steel mesh can vary depending on the area of use. However, it generally has the following basic features:

- Material Quality: Steel mesh is produced from steel rods with qualities like ST IVB or ST III. These steels are materials with high tensile strength.

- Strength: It has high tensile and compressive strength, effectively distributing the loads within the concrete.

- Standard Dimensions: Typically, it is 2.15 meters wide and 6 meters long as a standard. However, project-specific dimensions can also be applied.

- Weld Points: The rods of the steel mesh are joined to each other by welding. The durability of these weld points affects the overall performance of the material.

- Corrosion Resistance: Steel mesh is generally made resistant to corrosion through measures like zinc coating.

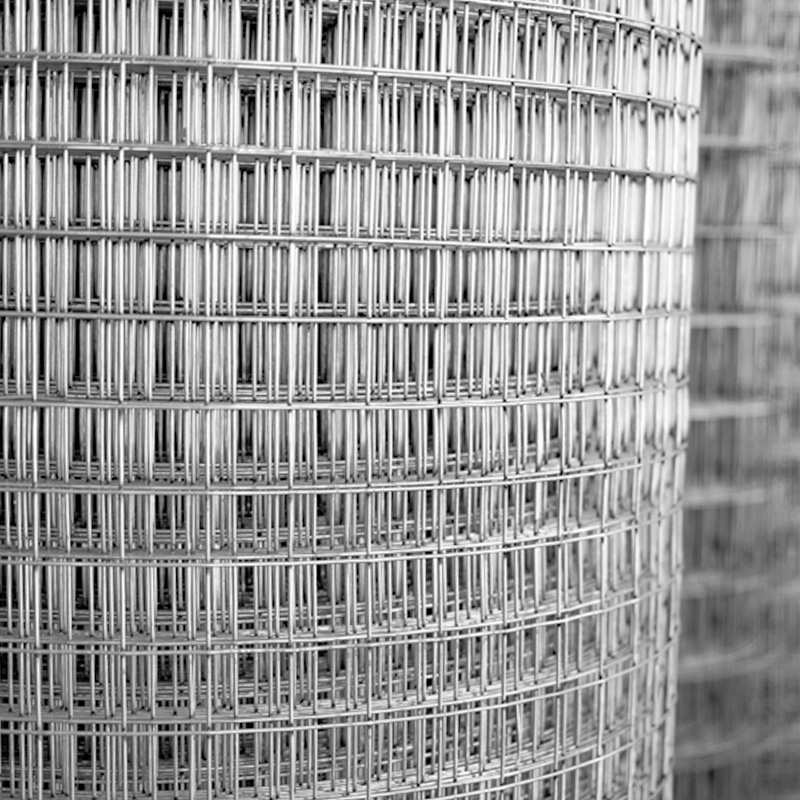

How Is Wire Mesh Produced?

The production of wire mesh involves a multi-step process. Modern wire mesh manufacturers use automation systems in these processes to ensure fast and efficient production. Here are the basic steps:

- Raw Material Supply: Steel bars are used as the main material in wire mesh production. These bars are typically selected from materials with high tensile strength.

- Cutting: Steel bars are laser cut to specified dimensions. The precision of this process affects the quality of the final product.

- Straightening: The cut bars are arranged neatly and freed from tension.

- Welding: Bars are joined using automatic welding machines. This step forms the foundation of the durability of the wire mesh.

- Final Inspection and Packaging: After welding is completed, the products are inspected. Products that meet quality standards are packaged and prepared for shipment.

What Materials Are Used in the Production of Steel Mesh?

The following essential materials are used in the production of steel mesh:

- Steel Rods: Used as the main material, steel rods determine the durability and strength of the steel mesh. These rods are often chosen from materials with a high carbon content.

- Coating Materials: Coating with zinc or similar materials is applied to ensure resistance to corrosion.

- Welding Wire: Wires made from suitable materials for the welding process are used. This material contributes to the longevity of the mesh.

- Automation Systems: Modern steel mesh manufacturers use automated machines and robotic systems during the production process to ensure product standardization.

What Are the Standard Dimensions of Steel Mesh?

Steel mesh is one of the steel products widely used in the construction industry for durability and safety. The standard dimensions of steel mesh can vary according to different project needs. However, in general, they have the following characteristics:

- Bar Diameter: Ranges from 4 mm to 12 mm.

- Mesh Sizes: Produced in regular intervals such as 10x10 cm, 15x15 cm, and 20x20 cm.

- Dimensions: Standard sheet sizes are generally 2.15x5 m or 2.40x6 m. However, special dimensions can also be requested according to needs.

These standards are determined by manufacturers for use in both local and international projects, and steel mesh manufacturers offer their products within this framework.

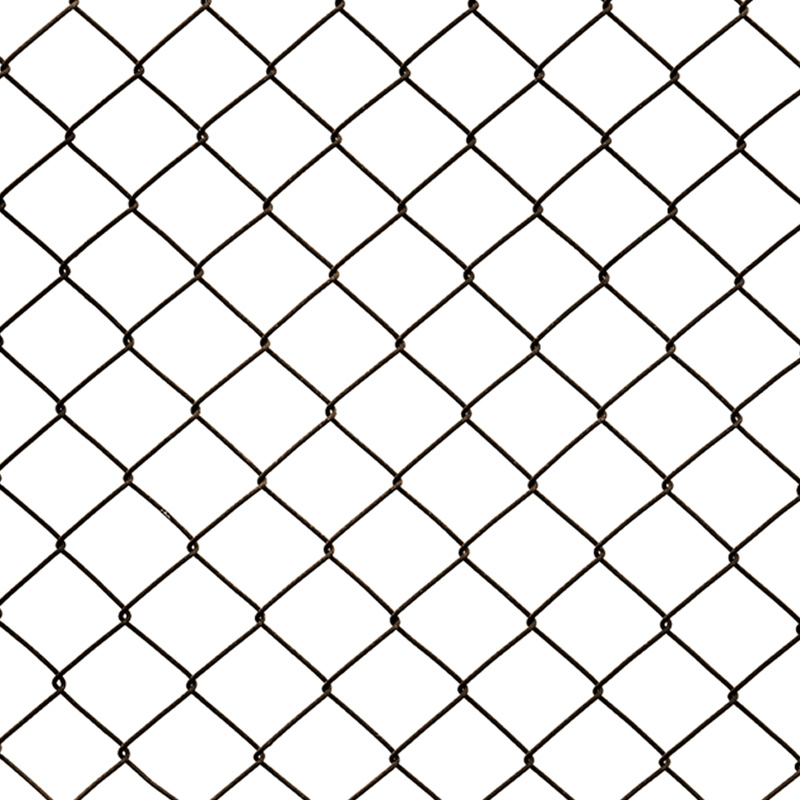

What Types of Mesh Do Steel Mesh Manufacturers Produce?

Steel mesh manufacturers offer specialized products suitable for various projects and applications. The following types are commonly found in steel mesh production:

- Flat Mesh: Generally used in reinforced concrete projects. It has standard sizes and offers various mesh spacings.

- Roll Mesh: More flexible and often preferred in lightweight construction projects.

- Galvanized Mesh: Used in outdoor projects since it is resistant to corrosion.

- Stainless Steel Mesh: Preferred in industrial applications and projects requiring longevity.

- Decorative Mesh: Specially manufactured for architectural designs.

These types provide different levels of durability and flexibility according to the needs of the projects.

For What Purposes Is Steel Mesh Used in the Construction Sector?

Steel mesh stands out as a versatile material in the construction sector and is commonly used in the following areas:

- Reinforced Concrete Structures: In structures like buildings, bridges, and tunnels, steel mesh enhances the durability of concrete.

- Floor Coverings: Used in industrial floors and parking areas to provide resistance against heavy loads.

- Historical Building Restoration: Used in strengthening old buildings, extending their lifespan.

- Prefabricated Structures: Widely used in prefabricated structures where quick installation is required.

- Outdoor Applications: Offers decorative yet durable solutions for garden walls, railings, and fence systems.

The broad range of applications for steel mesh makes it important to apply the correct standards in its production and assembly.

What Should Companies Producing Steel Mesh Pay Attention To?

The production of steel mesh requires great care in terms of both quality and safety. Steel mesh manufacturers should pay attention to the following points:

- Use of Quality Raw Materials: The steel used must comply with international standards.

- Technological Equipment: Producing with modern machines increases precision and speed.

- Testing and Inspections: Testing the durability and flexibility of the steel mesh ensures product quality.

- Compliance with Standards: Adherence to local and international standards should be a priority in the production process.

- Eco-Friendly Practices: Conducting production with waste management and recycling techniques that are environmentally conscious.

- Adaptation to Customer Demands: Offering custom sizes and solutions is important to meet the diverse needs of the industry.

These factors ensure that companies producing steel mesh can succeed in the sector.

What Are the Essential Factors to Consider in the Installation of Steel Mesh?

The installation of steel mesh is a critical phase for using the product efficiently and ensuring the durability of the structure. The following factors should be considered for the installation to be successful:

- Surface Preparation: The ground should be clean and smooth before installation.

- Correct Placement: The mesh should be placed according to its measurements, and connection points should be properly aligned.

- Connection Elements: Suitable connection elements should be used to ensure stability.

- Concrete Pouring: Concrete poured over the mesh should be spread evenly, ensuring the mesh is fully integrated.

- Control and Testing: After installation is complete, the durability and stability of the structure should be tested.

Paying attention to these details in steel mesh installation ensures both safety and longevity.

Steel mesh is an indispensable part of the construction sector due to its versatile use, durable structure, and aesthetic features. Steel mesh manufacturers can meet market demands by prioritizing quality at every stage from production to installation. The proper use of this product enhances both the durability and visual appeal of structures.

TR

TR

Box Profiles

Box Profiles Sheets

Sheets Pipes

Pipes Rolling Mill Products

Rolling Mill Products Construction Steels

Construction Steels Steel Meshes

Steel Meshes Construction Steel

Construction Steel Engineering Steels

Engineering Steels