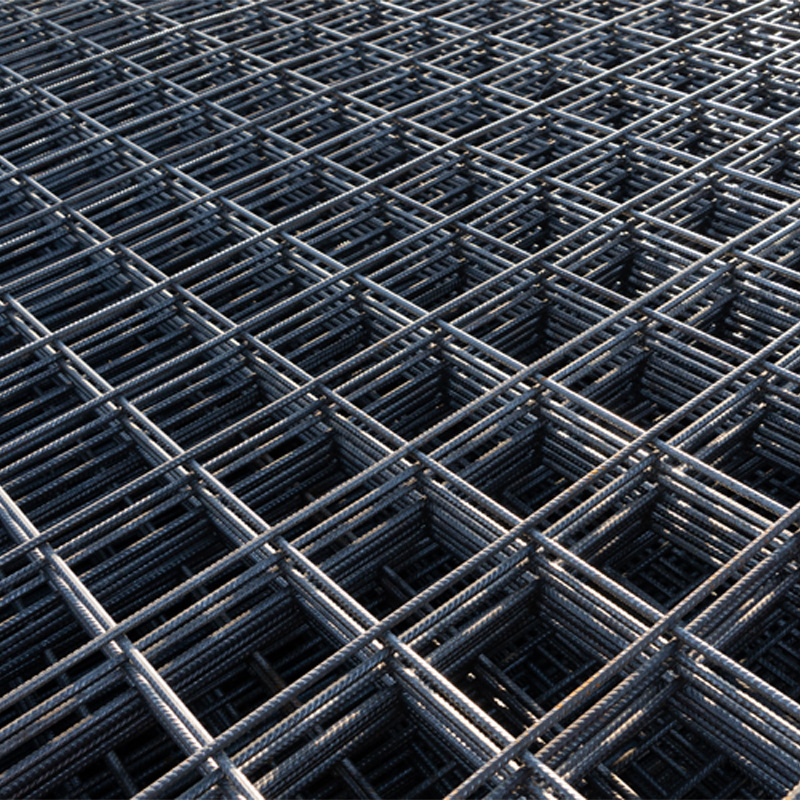

Reinforcement meshes are durable construction materials made of steel rods, used in the construction sector. They are preferred in reinforced concrete projects to prevent concrete from cracking and to ensure structural integrity. Used in many areas from foundations to floor coverings, and from columns to walls, reinforcement meshes contribute to building long-lasting structures by enhancing durability.

Concrete meshes are structural materials in the form of a mesh created by regularly combining steel bars, commonly used in reinforced concrete structures. They are used to enhance the durability of concrete and ensure structural integrity. Concrete meshes are an indispensable material, especially in the construction sector.

The main purpose of reinforced steel meshes is to enhance durability in reinforced concrete structures. They are commonly preferred in the following areas:

Reinforced Concrete Structures: Used in concrete elements like foundations, columns, and beams to increase the structure's strength.

Flooring: Used in places like factories and warehouses to prevent concrete floors from cracking.

Tunnels and Bridges: Ensures durability in structures exposed to high pressure and stress.

Precast Structural Elements: Used in precast concrete elements to achieve longevity.

The advantage of reinforced concrete is that it ensures the loads in the structures are distributed evenly, thereby reducing the risk of cracking and deformation.

What Materials Are Used to Produce Concrete Mesh?

The primary material used in the production of concrete mesh is steel. High-strength and flexible steel rods are woven together using special machinery. The steel wires that make up the mesh vary according to their diameter and quality.

The steel used in concrete mesh is made resistant to rust and corrosion, resulting in a long-lasting construction material. The knot points of the mesh wires are joined using special welding technology, increasing the structure's strength.

How Is the Durability of Concrete Mesh Tested?

A series of standard procedures are applied to test the durability of concrete mesh. These tests ensure both the material's quality and the structure's durability:

Tensile Test: The tensile strength of the steel rods is measured by applying a specific force. This test is used to evaluate the material's performance under load.

Weld Quality Test: The durability of the weld knot points of the mesh wires is tested with special devices.

Corrosion Test: Steel mesh is tested under laboratory conditions that mimic humid and acidic environments.

Load Distribution Test: The contribution of concrete mesh to the homogeneous distribution of loads on concrete is measured.

These tests are critically important to ensure that concrete with mesh performs maximally under all challenging conditions.

Where Is Concrete Mesh Used?

The versatile nature of concrete mesh makes it a preferred material in various fields. The following are prominent areas of use:

Industrial Structures: In factories, warehouses, and logistic centers, mesh concrete is preferred to enhance floor durability.

Infrastructure Projects: It offers solutions resistant to heavy loads in structures like roads, tunnels, and bridges.

Prefab Systems: It forms a durable structure in concrete panels, walls, and other prefabricated elements.

Agriculture and Livestock: Used in concrete floors and walls in agricultural structures.

Garden and Landscaping: Provides a durable and aesthetic appearance in hard ground arrangements.

Advantages of Concrete Mesh and Reinforced Concrete

Reinforced concrete stands out for both its durability and cost advantages. The use of mesh enhances both the flexibility and strength of the structure. These advantages make reinforced concrete indispensable in the modern construction sector.

What Should Be Considered When Choosing Concrete Mesh?

Concrete mesh is an important material frequently chosen in construction projects to enhance the durability of concrete. However, there are some critical points to consider when you decide to use concrete mesh in your projects.

Project Requirements: You should thoroughly analyze the characteristics of your project before selecting concrete mesh. Determining the required load-bearing capacity and durability features is very important.

Material Quality: The steel quality of the concrete mesh affects the product's longevity and durability. You should choose mesh made from high-quality steel.

Compliance with Standards: Check if the concrete mesh complies with national and international standards. Products that meet these standards can be safely used in your projects.

Size and Aperture Range: The dimensions and aperture range of the concrete mesh should be suitable for the characteristics of the area where it will be used. Thinner mesh is preferred for applications that do not require very high strength, while thicker steel rods are suitable for heavier loads.

Supplier Selection: It is important to purchase concrete mesh from a reliable and experienced supplier. This way, you can be assured of quality and receive technical support.

What Are the Standard Dimensions of Concrete Mesh?

The standard dimensions of concrete mesh can vary based on the diameter of steel rods and aperture spacing. Generally, the commonly used concrete mesh standards in the construction industry are as follows:

Mesh Thickness: Steel rods used in concrete mesh are typically between 4 mm and 12 mm. Thicker rods are suitable for heavier loads and more durable structures.

Aperture Range: In reinforced concrete applications, the aperture spacing is generally designed as 10 cm x 10 cm or 15 cm x 15 cm. These spacings allow for the concrete to distribute evenly.

Panel Sizes: Concrete mesh is usually offered in standard panels measuring 2.15 meters x 5 meters or 2 meters x 6 meters. However, for special projects, dimensions can be customized.

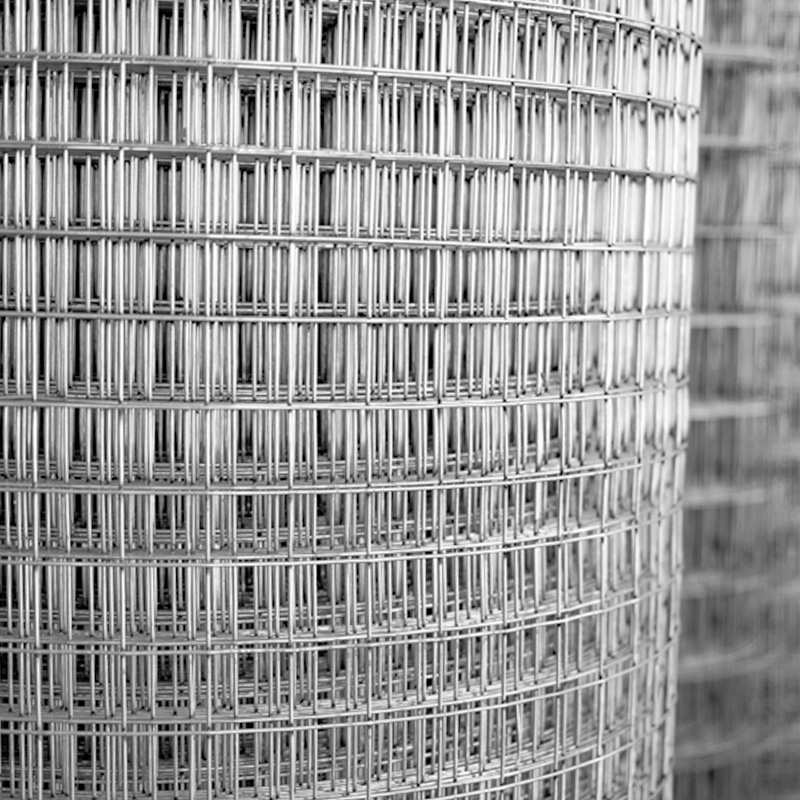

How Is Concrete Mesh Produced?

The production of concrete mesh begins with carefully designed and applied weaving of steel rods.

Raw Material Selection: The steel rods to be used in concrete mesh are selected from steel wires or rods of suitable quality.

Cutting: Steel rods are cut according to specified dimensions. Dimensional precision is very important at this stage.

Welding: The cut rods are joined according to predetermined aperture spacing. These processes are generally carried out with automatic welding machines.

Surface Coating: A protective coating may be applied to steel rods to prevent rusting. This coating can be done through galvanization or similar methods.

Quality Control: After production, the concrete mesh undergoes quality control tests. These tests are important to ensure the product's durability and compliance with standards.

What Are the Advantages of Using Concrete Mesh?

Using concrete mesh offers numerous advantages in construction projects. These advantages have made reinforced concrete more common.

Increases Durability: Concrete mesh enhances the resistance of concrete structures against cracking and deformation, contributing to the longevity of the structures.

Easy and Quick Application: Offering concrete mesh in standard size panels speeds up the application process, saving labor.

Homogeneous Distribution: Reinforced concrete applications provide homogeneous durability distribution within the concrete, which is crucial, especially in projects requiring high strength.

Cost Efficiency: Concrete mesh provides cost savings in the long term. Durable structures reduce repair and maintenance costs.

Environmentally Friendly: The reusability of concrete mesh reduces its environmental impact. Additionally, energy-saving technologies are used in its production.

Flexibility: Concrete mesh comes in various sizes and features that can be used in different projects and conditions, providing flexibility.

The selection, production, and use of concrete mesh play a very important role in the success of your projects. Choosing the right concrete mesh and using products that comply with standards will increase the durability of the structure and reduce your costs in the long run. With reinforced concrete applications, you can build modern and durable structures.

Common Features of Concrete Meshes and Cage Meshes

Although concrete meshes and cage meshes are construction materials used for different purposes, they share some common features. Here are the common points of the two mesh types:

1. Material Structure: They are generally produced from steel wires. Steel material stands out for its durability and longevity.

The surface of steel wires is usually ribbed (serrated), providing better adhesion with concrete.

2. Weave Pattern

Both concrete meshes and cage meshes have a regular weave pattern. Rods are connected vertically and horizontally to create a square or rectangular weave.

3. Durability and Strength

Both mesh types increase load-bearing capacity and strengthen structural durability.

Thanks to its steel structure, it is resistant to high pressure and tension.

4. Ease of Use

Since concrete and cage meshes are produced ready for use, their installation is easy and quick. It reduces labor time.

5. Application Areas

Both are used in the construction sector. Concrete meshes are more commonly used in reinforced concrete structures, while cage meshes are preferred in fence systems and animal shelters.

Both can be used for protection and support purposes.

6. Longevity

Both materials are produced to be resistant to external factors. They can be protected with coatings like galvanization to prevent rusting.

TR

TR