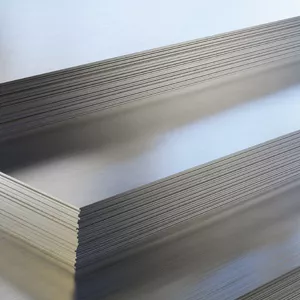

Galvanized sheet prices vary depending on many factors such as raw material costs and exchange rates. The international market conditions of steel raw material, the thickness of the galvanizing layer, and energy costs used in production processes directly affect these prices. Additionally, market competition conditions and seasonal campaigns can lead to notable fluctuations in galvanized sheet prices. When demand increases, prices tend to rise, while in periods of surplus stock, more competitive figures can be encountered. Deha Metal aims to offer suitable alternatives to its customers by keeping track of galvanized sheet prices.

Current Galvanized Sheet Prices

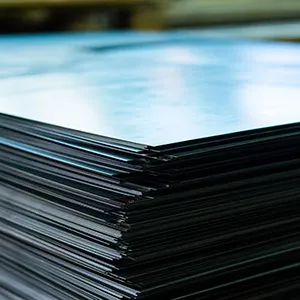

Galvanized sheets are obtained by coating steel with zinc to protect against corrosion. These products are preferred in many sectors such as construction, automotive, white goods, energy, and industry. Current galvanized sheet prices can change instantly based on developments in both local and global steel markets. The supply-demand balance of raw material domestically and internationally, logistics costs, steel producers' capacity utilization rates, and increases in energy costs are directly reflected in prices.

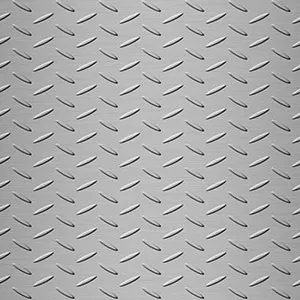

Furthermore, the thickness of the galvanizing layer is an important criterion considered in determining prices. As the coating thickness increases, the amount of zinc used will increase, leading to higher costs. Deha Metal provides different coating thicknesses for your projects and needs, offering advantages with competitive pricing policies.

Fluctuations in exchange rates, especially during periods when imported steel raw material is used, have a significant impact on galvanized sheet prices. Economic fluctuations in foreign markets, changes in customs duties, and international logistics costs also shape prices upwards or downwards. Therefore, those who want to learn current prices should regularly review market analyses or contact reliable suppliers like Deha Metal.

How Are Galvanized Sheet Prices Calculated?

Galvanized sheet prices are calculated by considering the weight of the sheet and the unit price. Additionally, the cost of galvanizing must be included in the calculation. The basic formula used in this process is as follows:

Price = Sheet Weight (kg) × Unit Price (TL/kg) + Coating Cost (TL)

- Sheet Weight: Calculated based on the dimensions and thickness of the sheet. Steel density is generally assumed to be 7.85 g/cm³. For example, a sheet measuring 1,000 mm x 2,000 mm and 1.5 mm thick can be found to weigh approximately (1000 × 2000 × 1.5 × 7.85) / 1,000,000 = 23.55 kg (approximately).

- Unit Price: Refers to the prevailing steel cost in the market. Exchange rates, raw material prices, and general supply-demand conditions can constantly change this value.

- Coating Cost: A cost item that varies based on the thickness of the galvanizing and the amount of zinc used. A thick galvanizing layer provides longer protection against rust while also increasing production costs.

For a simple example: Assuming the unit price of a 23.55 kg sheet is 30 TL/kg and the galvanizing adds an additional cost of 10 TL:

Price = 23.55 × 30 + 10 = 706.5 + 10 = 716.5 TL

This example includes many parameters that can vary according to the project. Therefore, prices will vary for different sheet thicknesses, dimensions, or coating thicknesses. Deha Metal helps its customers perform the most accurate cost analysis by offering customized alternatives for each project.

How Are Galvanized Sheet Prices Determined?

Galvanized sheet prices emerge from a combination of several factors. Below are the main headings of these factors:

- Raw Material Supply and Demand: The global demand for steel raw material leads to increased prices. When there is a surplus supply, prices may remain stable or at lower levels for a while.

- Exchange Rate: If imported inputs are used in the production of galvanized sheets, fluctuations in the exchange rate are directly reflected in costs.

- Energy Costs: Steel production and galvanizing processes consume significant amounts of energy. Rising energy prices directly impact sheet prices.

- Coating Thickness: Thicker galvanizing layers that provide higher protection increase prices due to additional zinc usage.

- Production Technology: Modern and efficient production facilities can offer cost advantages in large-scale productions. This positively reflects on prices, while costs may remain high in facilities using more traditional methods.

- Transport and Logistics: The distance the product will be transported, transportation methods, and taxes also play a role in determining the final price.

Deha Metal provides fast and up-to-date information on galvanized sheet prices, offering solutions most suitable to the requirements of your project. Combining high quality with competitive figures, the company aims to be a reliable partner in both small-scale and large projects. You can benefit from the most advantageous prices in the industry by contacting Deha Metal according to the required length, thickness, and coating thickness.

TR

TR