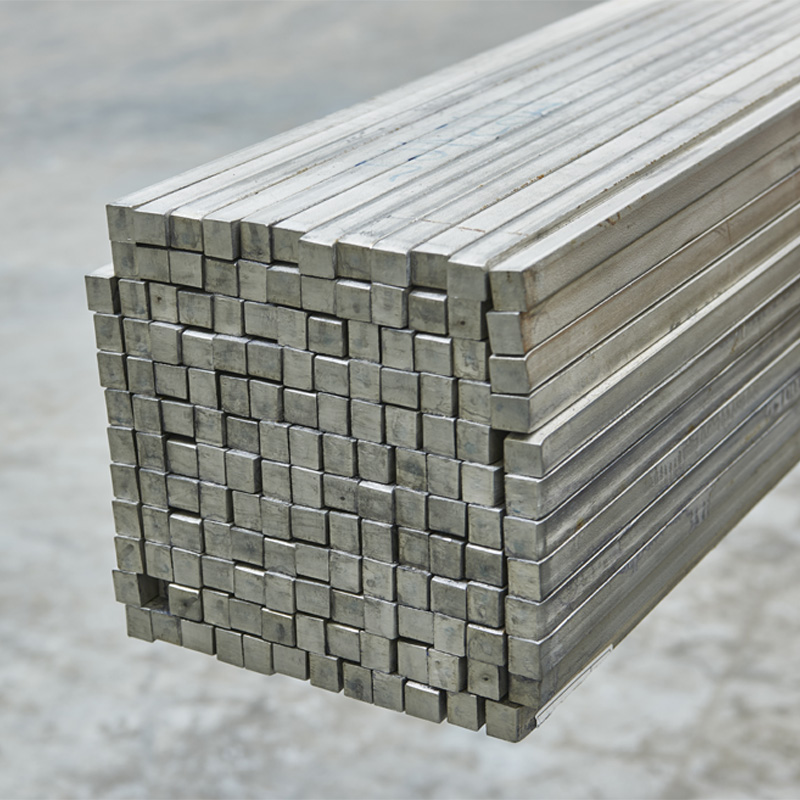

Engineering, a field that appears in many areas of our lives, is presented to everyone with the materials and structures it encompasses.

What Are Engineering Steels?

Some of the engineering steels offered to the market by Deha Metal, a leading company in its sector, with the approval of the Swedish-based SSAB company are;

– Toolox 33,

– Toolox 40,

– Toolox 44

This product, which falls under the class of engineering steels named Toolox 33, is marketed with pre-hardening and measures taken to prevent breakage. The most common area of use is plastic injection molds. To explain the material properties of Toolox 33 engineering steel;

– It has the ability to be easily processed.

– It has high toughness.

– It contains structural cleanliness with ESR quality. EPS stands for Erythrocyte Sedimentation Rate. It is named this way, taking the cleanliness of blood cells as an example.

– It can be welded easily and without problems.

– Patterns can be applied to it effortlessly.

– It has the ability to be polished easily.

This Toolox 33 steel, offered by Deha Metal, has several application areas. These include plastic injection molds, rubber molds, various mold sets, and different types of machines. To explain the material properties of another engineering steel, Toolox 40;

– Like in Toolox 30, it has structural cleanliness with ESR quality.

– It has high ductility. Ductility refers to the ability to stretch.

– It can be polished and patterned easily.

– It has the capability for welded manufacturing.

Toolox 40 has some areas of use. These include plastic injection and rubber molds, form forming molds, metal injection molds, and engineering applications. Another engineering steel is Toolox 44. To explain the material properties of Toolox 44 engineering steel;

– It has a structure subjected to a certain degree of pre-hardening.

– It possesses ESR structural cleanliness quality.

– It has high resilience at high temperatures.

– It has high flexibility.

– It is an engineering steel suitable for surface treatments.

– It is easy to polish and pattern.

To explain the areas of use of the Toolox 44 engineering steel;

– It can be used in high-temperature forging molds.

– It can be used in form forming, shaping, and cutting molds.

– Metal molds.

These engineering steels are one of the important components of the engineering and iron-steel work segment that plays a role in every area of our lives. These engineering steels hold some standard equivalents in their patents. These are; AISI, ISO, JIS. AISI stands for American Iron and Steel Institute. ISO stands for International Organization for Standardization. JIS stands for Japanese Industrial Standards Institute. Deha Metal, with an expert team and experience, offers services as a leading company in its sector.

TR

TR

Box Profiles

Box Profiles Sheets

Sheets Pipes

Pipes Rolling Mill Products

Rolling Mill Products Construction Steels

Construction Steels Steel Meshes

Steel Meshes Construction Steel

Construction Steel Engineering Steels

Engineering Steels