Stainless steel is a versatile material that has become an indispensable part of modern industry. With its durability, aesthetic appearance, and resistance to various environmental conditions, stainless steels have a very wide range of applications. Understanding the production process and fundamental properties of stainless steels helps us to comprehend why this material is so popular.

Stainless steel is a type of steel resistant to corrosion. It owes this property to the chromium element it contains. Stainless steels, which generally contain at least 10.5% chromium, gain resistance to rust as this element reacts with oxygen to form a protective passive layer on the steel surface. This material can also be enhanced with numerous alloying elements, for example, by adding elements such as nickel, molybdenum, and nitrogen to improve its properties.

Stainless steel manufacturing involves a complex process and requires a multi-step production chain. Stainless steel production generally consists of the following stages:

Raw Material Selection: For the production of stainless steels, main elements such as iron, chromium, nickel, and carbon are used. Combining these elements in the correct proportions determines the final properties of the steel.

Melting and Mixing: Raw materials are melted and mixed in furnaces. The electric arc furnace is often the primary component used in this process. During this step, chromium and other alloys are added to the steel.

Refining: The melted metal is purified from unwanted elements like sulfur and carbon. This stage is crucial for making the chemical composition of the steel purer.

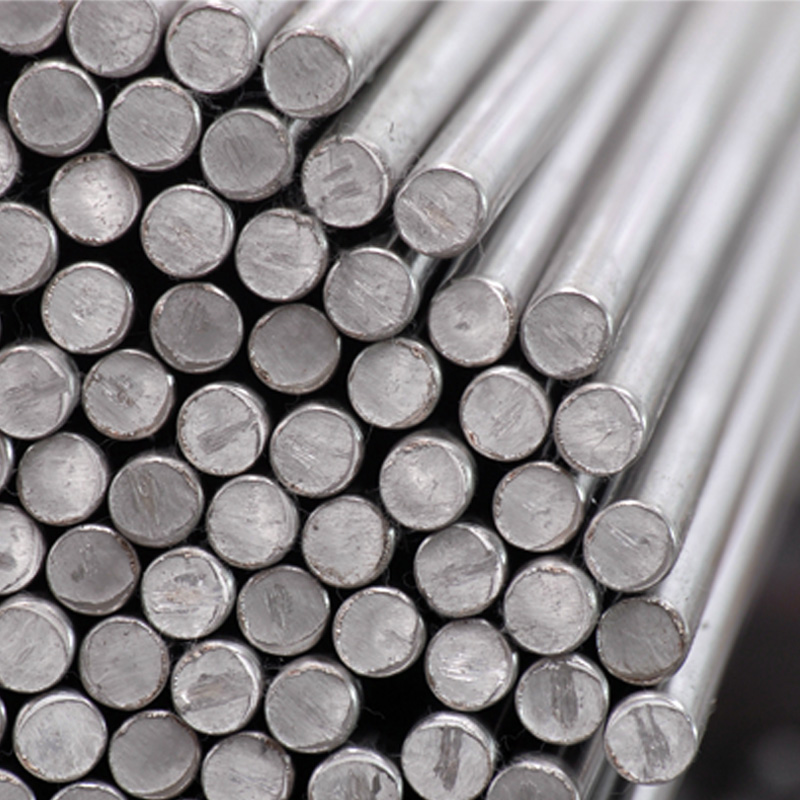

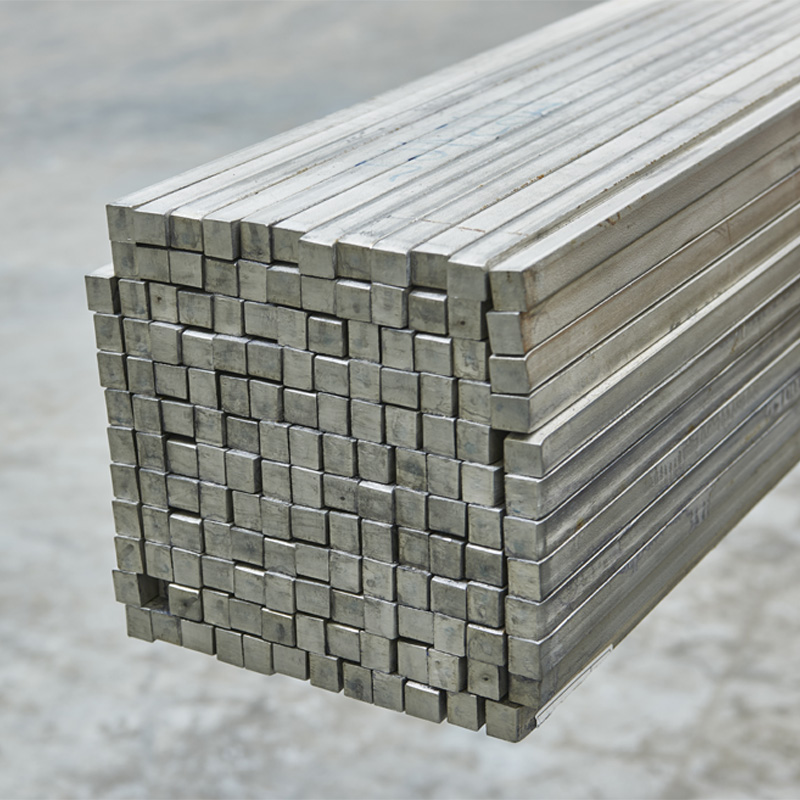

Casting: The refined stainless steel is poured into molds and shaped. This stage determines the initial form of the steel, produced in flat or long forms.

Heat Treatment: Various heat treatments are applied to the steel to enhance its durability. Annealing improves the material and prepares it for working conditions.

Finishing: The aesthetic appearance and surface quality of stainless steels are improved at this stage. Techniques such as polishing, acid cleaning, and coating are used.

Stainless steel manufacturing companies focus on optimizing these processes to enhance the properties of the material.

In Which Areas Are Stainless Steels Used?

The usage areas of stainless steels are quite broad due to their versatile properties. Here are some areas where stainless steels are commonly used:

Construction and Architecture: Stainless steel is used in skyscraper facades, stair railings, and decorative elements. Its corrosion resistance and elegant appearance make it stand out.

Food and Beverage Sector: Due to its hygienic nature, it is preferred in food processing equipment and storage tanks.

Medical and Pharmaceutical: Stainless steels are used in the production of medical devices and surgical equipment. Its antibacterial and easy-to-clean nature offers an ideal solution for this sector.

Transportation and Automotive: Stainless steel is used in trains, ships, and cars due to its durable structure. Exhaust systems and fuel tanks are striking examples of this.

Chemical and Petrochemical: Stainless steel is preferred in chemical reactors and storage tanks due to its resistance to chemicals.

What Are the Key Features of Stainless Steels?

The reason why stainless steels are used in such a wide range is due to their key features. The features of stainless steel can be summarized as follows:

Corrosion Resistance: One of the most important features of stainless steels is their corrosion resistance. This provides a significant advantage, especially in environments with seawater or industrial chemicals.

Strength: High durability and hardness allow stainless steel to be preferred in a wide variety of applications.

Aesthetic Appearance: Stainless steel has a modern and stylish look, making it a common material in decoration and architecture.

Hygienic Structure: Its easy-to-clean surface and ability to prevent bacterial growth play a crucial role in the food and medical sectors.

Longevity: Stainless steels offer a long-term economic solution due to their longevity.

Recyclability: It is an environmentally friendly material that can be completely recycled.

Factors Stainless Steel Manufacturers Should Pay Attention To

Stainless steel manufacturers should pay attention to the following factors to be successful in production and marketing processes:

Material Quality: Care should be taken in the selection of raw materials for the production of high-quality stainless steel.

Technological Innovations: Companies that use advanced technology in stainless steel manufacturing gain a competitive advantage. New technologies are critical for reducing costs and improving quality.

Environmental Responsibility: Environmentally friendly production techniques are demanded by both customers and regulatory bodies. Stainless steel manufacturers should focus on reducing their carbon footprint.

Customer Demands: Companies that produce stainless steel should understand the specific needs of customers and offer solutions tailored to these demands.

Training and Certification: Having the necessary certifications to document expertise in the field and enhance personnel competence provides a significant advantage.

,

What Are the Advantages of Stainless Steels?

Stainless steels are known as a versatile and durable material in the modern manufacturing world. There are many reasons why stainless steels are preferred across various industries due to their properties. Primarily, this material has very high corrosion resistance. This feature is achieved by adding chromium to the material during stainless steel production. Chromium forms a protective oxide layer on the surface of the steel, providing resistance against corrosion.

Additionally, stainless steels are environmentally friendly and recyclable. This feature provides a significant advantage in responding to the ever-increasing demands on companies producing stainless steel. Stainless steels also have an aesthetic appearance. Its bright and attractive surface makes it a popular choice in architectural and decoration applications.

Another significant advantage is its durability and long lifespan. The properties of stainless steel ensure long-lasting performance even in challenging conditions. At the same time, its hygienic nature easily meets the specification requirements in the food and health sectors. These features make it easier for companies manufacturing stainless steel to reach a broader audience with their products.

In Which Sectors Is Stainless Steel Manufacturing Preferred More?

Stainless steel manufacturing plays a critical role in many different sectors. The durability and corrosion resistance of this material make it indispensable in certain industries.

Food and Beverage Industry: Due to its hygienic and easy-to-clean nature, stainless steels are extensively used in food processing facilities. The main reason for being widely preferred in areas such as storage tanks, kitchen equipment, and production lines is that the material does not pose harm when in contact with food and is resistant to microbial growth.

Health and Medical Industry: The properties of stainless steel make its use possible in the production of medical devices and surgical tools. Its antibacterial nature and resistance to sterilization processes make it stand out in this sector.

Automotive and Aerospace: Stainless steel manufacturing is used in critical sections like chassis, exhaust systems, and safety equipment in the vehicle industry. In aerospace, it is a significant material because of its balance of lightness and strength.

Energy and Petrochemicals: Stainless steels are used in energy plants and oil refineries for the production of pipelines, tanks, and heat exchangers. Its ability to withstand the harsh conditions of these sectors increases its popularity.

Architecture and Construction: Due to its aesthetic and durable nature, stainless steels are preferred for building facades, railings, and interior design. Stainless steel manufacturers provide unique solutions to ensure architecture is long-lasting and attractive.

What Are the Differences Between Stainless Steels and Carbon Steels?

Stainless steels and carbon steels have distinct differences. These differences primarily affect the application areas and performance of the materials.

Corrosion Resistance: Stainless steels are resistant to corrosion due to the chromium they contain. Carbon steels, however, are more prone to rust when exposed to moisture and oxygen.

Strength and Hardness: Carbon steels are generally harder and more durable, but the properties of stainless steel provide a much longer-lasting performance as they are less affected by deformation and thermal expansion.

Aesthetic: The bright surface and aesthetic appearance obtained from stainless steel production are more striking compared to carbon steels.

Cost: Carbon steels are generally more cost-effective compared to stainless steels. However, stainless steel manufacturers emphasize that this cost difference is balanced in the long term due to longer lifespan and less maintenance requirement.

Reasons for the High Corrosion Resistance of Stainless Steels

The main reason for stainless steels' resistance to corrosion is the chromium content within the material. During stainless steel manufacturing, chromium is added to the steel and reacts with oxygen, forming a thin passive film layer on the material's surface. This layer protects the lower layers of the steel from water, moisture, and chemicals, preventing rusting.

Additionally, different alloys of stainless steel can enhance the material's durability in specific environments. For example, adding elements such as molybdenum and nickel can make the steel more resistant to acid and salty water environments.

What Are the Different Types of Stainless Steels?

Stainless steel manufacturers develop different alloys to meet various industrial needs. These alloys are usually classified into four main groups:

Austenitic Stainless Steels: This group is the most commonly used type of stainless steel. It has high corrosion resistance and tensile strength. Types 304 and 316 stainless steels fall into this group.

Ferritic Stainless Steels: These steels, with lower chromium content, usually offer cost advantages. They are widely used in the automotive and white goods industries.

Martensitic Stainless Steels: Preferred for applications requiring high strength and hardness. Stainless steels in this group are typically used in knives and medical instruments.

Duplex Stainless Steels: Combining both austenitic and ferritic structures, these steels offer very high durability and corrosion resistance. They are preferred in challenging conditions like petrochemical and maritime industries.

The properties and different types of stainless steels provide extensive diversity in industrial application areas. Companies producing stainless steel continue to offer innovative solutions to various industries by evaluating the versatility of this material.

TR

TR