Transmission shafts are one of the cornerstones of the modern machinery and automotive industry. These products play a key role in power transmission and ensure the smooth operation of mechanical systems by efficiently transmitting movement. Here is our guide covering everything you need to know about transmission shafts.

Transmission shaft is a mechanical component designed to transmit rotational motion and torque from an engine or power source to a mechanism or working components. These shafts are commonly used in automobiles, trucks, industrial machines, and specialized equipment. The primary function of transmission shafts is to transfer motion and force from one point to another with minimal loss.

Transmission Shaft Features

Durability: Transmission shafts are designed to withstand high torque levels.

Precision: Being perfectly balanced helps minimize vibration and noise.

Long Lifespan: Material and manufacturing quality ensure the shafts have a long lifespan.

Transmission shafts are typically manufactured from special steels considering criteria such as durability, flexibility, and weight. The most commonly used materials are:

Transmission Steel: Transmission steel is a material that offers high strength and hardness, and it is commonly preferred in transmission and axle systems. This material is usually hardened or tempered to enhance fatigue resistance.

Alloy Steels: Contains carbon and special alloys. Used for lighter yet durable materials.

Composite Materials: Composite materials like carbon fiber may be used in certain special applications due to their lightweight and strength properties.

Transmission shaft material is determined based on the function of the system and loading conditions. For example, in high-performance sports cars, lightweight and durable materials are preferred, while heavier and harder materials are selected for industrial machines.

What Are the Dimensions of a Transmission Shaft?

Transmission shaft dimensions vary depending on the system's design and requirements. Standard sizes in terms of diameter and length can be classified as follows:

Transmission Shaft Diameters:

Small diameters (e.g., 20-30 mm): For light loads.

Medium diameters (e.g., 50-80 mm): Standard automotive applications.

Large diameters (e.g., 100 mm and above): Heavy load industrial applications.

Length: Depending on the area of use, transmission shafts can be of different lengths. In automotive, shafts ranging from 1-2 meters are common.

Precision: Precise measurements are crucial for the efficient operation of the system. Shaft diameters are determined along with tolerance values.

These measurements play a vital role in terms of compatibility and performance among the features of a transmission shaft.

How Is a Transmission Shaft Manufactured?

The manufacturing process of transmission shafts consists of many steps. Each of these steps is carefully conducted to maximize material durability and product quality. Here are the main steps in transmission shaft production:

Raw Material Selection: Suitable steel or alloy material is chosen. The material undergoes quality control tests prior to production.

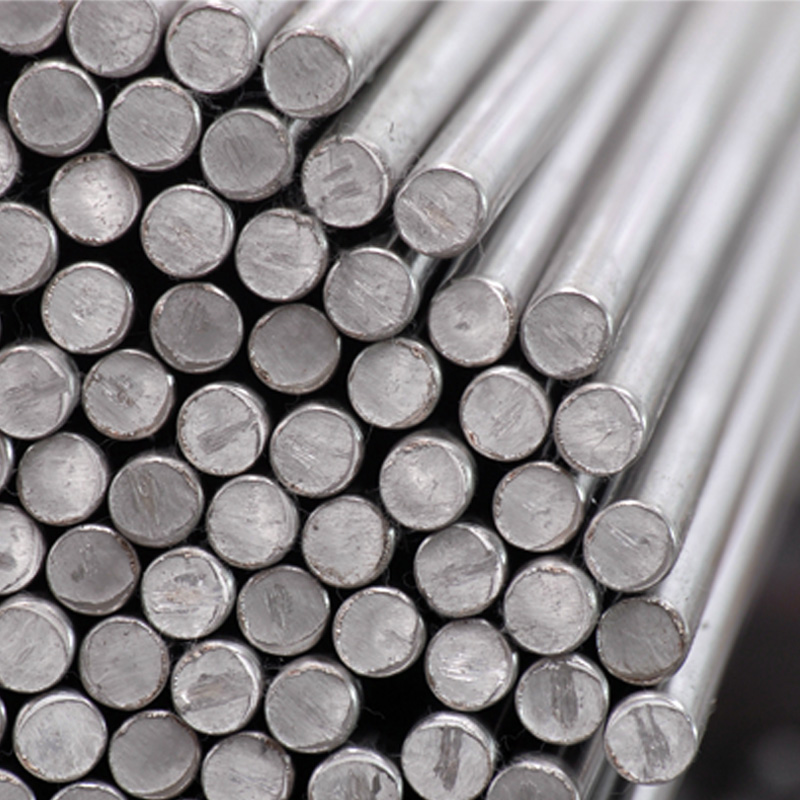

Initial Shaping: Ductile steel bars are shaped using special casting and rolling techniques.

Heat Treatments: Processes such as tempering and hardening are applied to increase strength.

Turning and Milling: Precise machine processes are carried out to achieve exact dimensions of the shaft.

Balancing: Any imbalance on the outer surface of the shaft is eliminated for smooth operation.

Coating and Final Layer: Special coating processes may be applied to increase corrosion resistance. Galvanizing is used in some applications.

Where Is Transmission Steel Used?

Transmission steel has a wide range of applications. The main areas of use are:

Automotive Industry:

Commonly used in vehicles' transmission, axle, and differential systems.

Provides a combination of lightweight and durability in sports cars.

Industrial Machines:

Suitable for applications requiring high torque.

Marine:

Offers durability for power transmission in marine engines.

Agricultural Machinery:

Used in tractors and similar machines for long life and durability.

Aerospace:

Meets the need for lightweight and durable materials.

Transmission shafts are critical in the industry and automotive sector. In their design and production, factors such as transmission shaft features and transmission shaft diameters are prioritized. They offer solutions for all systems seeking reliability in power transmission.

What Are the Features of a Transmission Shaft?

A transmission shaft is an important component used to transmit an engine's movement and power between the motor and wheels. To function successfully, this component needs to possess specific features.

Durability: The transmission shaft is subjected to very high torque and rotational forces. Therefore, it must be very durable. The mechanical strength of the material, particularly fatigue resistance, is important at this point.

Flexibility: A good transmission shaft should be flexible and exhibit a durable structure against impacts. This feature prevents damage to the structure even with sudden force changes.

Smooth Surface: The surface of the transmission shaft must be smooth to minimize friction and wear during rotational movement.

Precise Balancing: The shaft should not cause vibration during operation and should provide balanced force transmission between the motor and wheels.

How Do the Mechanical Properties of Transmission Steels Change?

Transmission steels enhance their mechanical properties through various processes. These properties change depending on the following factors:

Carbon Content: Transmission steels are usually produced from medium carbon or alloyed steels. A high carbon ratio increases hardness and wear resistance, whereas formability may decrease.

Heat Treatments: Processes such as hardening, annealing, and tempering applied to transmission steels optimize the strength and hardness of the material, making the shaft more durable and long-lasting.

Alloying Elements: Elements such as manganese, chromium, molybdenum, and nickel increase the fatigue resistance and hardness of the material. These elements also enhance the formability and heat treatment sensitivity of the steel.

Surface Hardening: Techniques such as nitriding and carburizing are used in transmission shaft production to increase wear and surface resistance of the material.

What Material Is a Transmission Shaft Made Of?

A transmission shaft is typically made of steel. However, the type of steel used may vary depending on the application's requirements:

Medium Carbon Steels: Providing high strength and good formability, this material is often preferred due to its cost-effectiveness.

Alloy Steels: Used for more demanding conditions, alloy steels are enriched with elements such as manganese, chromium, and nickel, offering high strength and fatigue resistance.

Composite Materials: Carbon fiber and similar composite materials may be used when lighter yet durable materials are needed, especially in performance vehicle applications.

What Are the Common Failures in a Transmission Shaft?

Over time, transmission shafts can wear or lead to various malfunctions. The most commonly encountered problems are:

Fluctuating Vibrations: Vibrations occur due to the imbalance or damage of the shaft, often resulting from the disturbance of the shaft's precise balance.

Internal Breaks or Cracks: Extended usage or overloading can cause cracks or breaks in the shaft's internal structure. Such failures may require replacing the shaft as they cannot be repaired.

Wear: Over time, friction causes wear on the shaft surface, which may affect its ability to perform its task.

Connection Issues: Loosening or damage of the connection components at the shaft's ends can impede the system's operation.

What Is the Connection Between Transmission Shafts and Case-Hardening Steels?

The connection between transmission shafts and case-hardening steels is a critical process aimed at enhancing the durability of transmission systems. Case hardening is a heat treatment method used to harden the surface of steels, frequently preferred for components under high mechanical stress like transmission shafts.

Connection of Case-Hardening Steels with Transmission Shafts:

Surface Hardness: Case hardening creates a hard layer on the surface of steel, thus increasing the durability of transmission shafts under high load and wear conditions.

The hard layer formed on the surface prevents friction and wear in moving parts like gears and shafts.

Core Flexibility: In the case hardening process, while the surface of the steel is hardened, the inner part remains softer and more flexible. This feature prevents the breaking of the inner part of transmission shafts, reducing the risk of breakage even under high loads.

Flexibility allows the shafts to withstand impacts without cracking or breaking.

Wear Resistance: In environments where transmission shafts operate, intense friction and wear occur. Case hardening provides resistance against such effects by creating a hard layer on the surface.

Especially in gear systems, it ensures that steel shafts work longer and more efficiently.

Hardness Profile: Case-hardening steels increase surface hardness while leaving lower hardness in inner parts. This feature provides longer life and load-carrying capacity in transmission shafts.

Lower hardness protects shafts from external impacts, making them durable against crashes.

Load Carrying and Safety: Transmission shafts are critical parts that convey engine power. Case hardening enhances the load-carrying capacity of these shafts.

Forces applied to the shafts are countered more effectively by the hardened surface of steel, increasing safety.

What Are the Diameters of Transmission Shafts?

Transmission shaft diameters can vary according to the type and characteristics of the vehicle. Generally, the diameters of transmission shafts used in cars and light commercial vehicles range from 25-75 mm. However, in heavy-duty vehicles and industrial applications, this diameter can be larger. Here are the features of transmission shafts with different diameters:

Small Diameter Shafts: Preferred for lighter and more compact designs. Typically used in low-torque applications.

Medium Diameter Shafts: Offer both durability and versatility. These shafts are installed in most cars and light commercial vehicles.

Large Diameter Shafts: Used in heavy load-bearing trucks and industrial machines. Larger diameters are suitable for applications requiring high torque and durability.

Transmission shafts are a critical component for effectively transmitting a vehicle's power. Transmission shaft features may vary according to the environmental requirements in which they are used. Material selection and mechanical processes ensure optimization of transmission shaft diameters and features.

Regular maintenance and inspection are essential to prevent failures. This not only enhances vehicle performance but also prolongs the service life of the transmission shaft. Being knowledgeable about transmission shaft features and diameters is crucial for making correct selections and reducing costs in the long term.

TR

TR