What are the Physical Properties of Tool Steel?

Tool steels offer a comprehensive profile in terms of tool steel properties.

Hardness and Durability

Thanks to their special chemical components, tool steels offer very high hardness and wear resistance. This feature allows them to maintain their functionality for a long time.

Heat Resistance

They are resistant to high temperatures that occur during processing. This criterion is of vital importance for industrial cutting and shaping tools.

Wear Resistance

Many functional areas are subject to intense wear. Tool steels minimize this effect and offer extra performance.

Hot and Cold Heat Treatments

Tool steels are designed to suit hot and cold heat treatments and thus show resistance to various shaping techniques.

What are the Differences Between Tool Steel and Carbon Steel?

Tool steel and carbon steel are two important types of steel used in different applications. However, they differ significantly in terms of their properties and areas of use.

Composition and Structural Differences

Tool steel falls into the alloy steel group and has features such as high hardness, durability, and heat treatment capacity. This type of steel typically contains alloy elements like chromium, vanadium, molybdenum, and tungsten. These elements enhance the properties of tool steels, making them resistant to wear, heat, and impact.

Carbon steel, on the other hand, consists mainly of carbon and iron. It is rich in alloy elements, although in lower quantities compared to tool steel. Carbon steels generally have lower hardness and are easily formable. Therefore, they are frequently preferred in construction, pipe production, and the automotive sector.

Mechanical Properties

Tool steels stand out with their high strength and wear resistance. Carbon steel usually has a more flexible structure, making it ideal for applications requiring impact resistance.

Areas of Use

Tool steel is used in applications requiring high precision, such as cutting tools, molds, drill bits, and punches. Carbon steels are commonly preferred in heavy industrial projects such as bridges, buildings, and shipbuilding.

What are the Application Areas of Tool Steel?

Tool steel is used in a wide variety of applications across different industries. Here's a detailed analysis of the application areas of tool steel:

Cutting Tools

Due to its high hardness and durability, tool steel is preferred for cutting tools used in the metalworking industry. Tools such as drill bits, lathe cutters, and saw teeth are made with tool steel.

Mold Production

Tool steel is used in plastic injection molds, forging molds, and metal stamping molds. In mold production, durability and heat resistance are of great importance.

Automotive Industry

In automobile parts production, especially in engine components and transmission gears, various tool steels are preferred. Such applications require longevity and wear resistance.

Construction Sector

Thanks to their properties, tool steels are used in the production of durable and reliable tools necessary for the construction sector. For example, blades and drilling bits of heavy machinery are made from this material.

Aerospace and Defense Industry

In applications requiring high performance and reliability, different types of tool steel are indispensable. Special tools used in aviation and weapon production in the defense industry frequently use these steels.

How is Tool Steel Hardness Measured?

Tool steel hardness is a critical parameter for determining the durability and performance in application areas. Rockwell, Vickers, or Brinell tests are generally used for measuring hardness.

Rockwell Hardness Test

The Rockwell test is one of the most commonly used methods for measuring hardness. In this test, a specific load is applied to the surface of a steel, and the indentation depth on the surface is measured. Tool steel hardness is usually expressed with the Rockwell C scale (HRC).

Vickers Hardness Test

The Vickers test uses a small diamond pyramid tip to measure material hardness. This method is ideal for measuring the hardness of thin materials and small parts.

Brinell Hardness Test

Typically used for measuring the hardness of large and heavy parts, the Brinell test involves pressing a wide ball onto the surface with a certain force and calculating the hardness value based on the diameter of the indentation.

What Should Companies Selling Tool Steel Pay Attention To?

Companies selling tool steel must pay attention to several important factors to ensure the quality of their products and customer satisfaction.

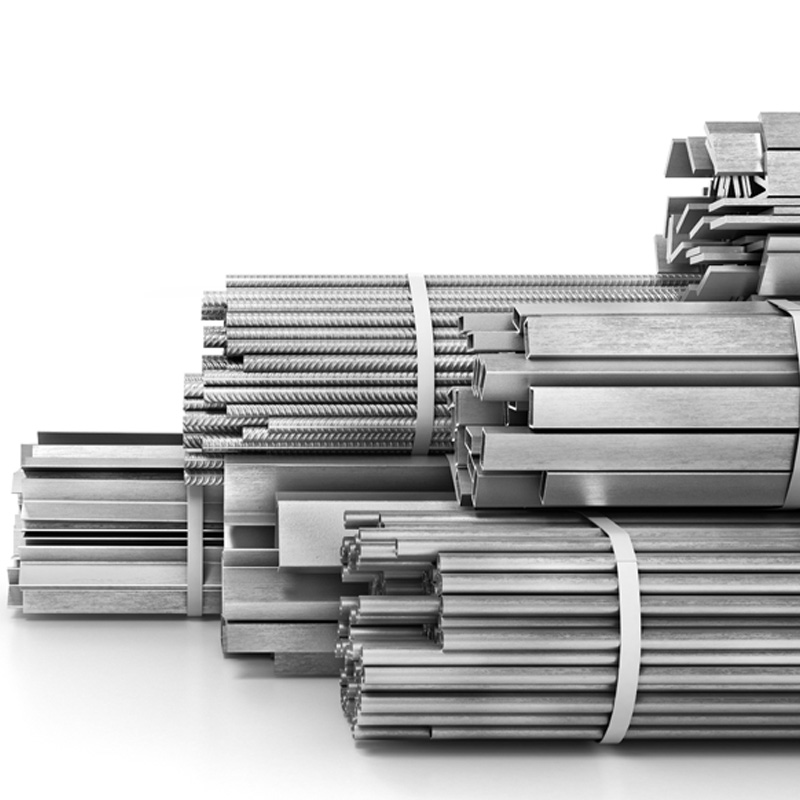

Product Variety

Companies selling tool steel should offer a wide range of products to meet the diverse needs of their customers. For example, different types of tool steel such as hot work, cold work, and high-speed steels should be available in stock.

Quality Certifications

It is crucial for the products offered to have quality certifications. Standards like ISO 9001 or similar, verify the products' reliability.

Technical Support and Consulting

Companies selling tool steel should provide technical support and consulting services to help their customers choose the right material. This type of support is particularly valuable for new businesses.

Logistics and Delivery

Timely delivery is a critical factor for customer satisfaction. Companies selling tool steel should have a strong logistics infrastructure and deliver their products seamlessly.

Competitive Pricing

Pricing policy should be carefully determined to compete in the market. Moreover, prices should be appropriate without compromising quality standards.

What is the Corrosion Resistance of Tool Steel?

The corrosion resistance of tool steel depends on its alloy components and type of steel. Some types of tool steel are specially designed to provide high corrosion resistance.

Stainless Tool Steels

Stainless tool steels increase corrosion resistance due to chromium content. These steels are suitable for use in humid and chemical environments.

Special Coatings

Among the properties of tool steels are special coatings that enhance corrosion resistance. Processes like nitriding or PVD coating protect the surface of the steel and extend its lifespan.

Tool steels with low corrosion resistance should be regularly maintained. Lubrication and cleaning processes will be effective in preserving the performance of the steel.

The properties of tool steel and tool steels emphasize the importance of this material in industrial applications. Companies selling tool steel gain a competitive advantage with quality products and customer-focused service, while users benefit from the advantages of this steel type, such as durability, hardness, and corrosion resistance.

TR

TR