Carbon steels emerge as one of the most important materials in the steel industry. These steels are primarily composed of carbon and iron elements and are used in a wide variety of industrial fields with different carbon contents. They have very important properties ranging from strength to flexibility, and these properties that determine the application areas of steels vary with the carbon ratio.

Carbon steels are a metal alloy where iron and carbon are the main components, typically containing small amounts of other elements. In these steels, the carbon content ranges from 0.02% to 2.1%. As the carbon content increases, the hardness and strength of the steel increase, while its ductility decreases. Therefore, the carbon content of steels is one of the most critical factors determining their properties.

Carbon steels are categorized into low-carbon, medium-carbon, and high-carbon steels. This classification determines the mechanical properties and applications of the steel. The properties of carbon steel cover a wide range from strength to ductility of this alloy.

Carbon steels play very important roles in many industries due to their wide range of properties. These materials:

Construction and Building: Low carbon steels are used in structural applications like buildings and bridges due to their flexible structures. The strength and durability properties of these steels provide an advantage in this sector.

Automotive Industry: The durability and cost-effectiveness of carbon steels are among the main reasons for their preference in the production of automotive parts.

Machinery and Equipment Manufacturing: Medium carbon steels are widely used in machines and industrial equipment due to their strength and ability to withstand heavy loads.

Energy and Infrastructure: High carbon steels are often preferred in turbines working in power plants and advanced engineering projects.

How Does Carbon Content Affect the Strength of Steels?

The carbon content directly affects the strength, hardness, and impact resistance of steel.

Low Carbon Steels: Carbon content ranges from 0.05% to 0.30%. They have a softer structure and are easily formable. Their strength is low, but they have high flexibility.

Medium Carbon Steels: Contain 0.30% to 0.60% carbon. They balance strength and hardness. Commonly used in manufacturing mechanical parts.

High Carbon Steels: Carbon content is above 0.60%. These steels are very hard and durable, but they are also more brittle.

Increasing the carbon content to enhance strength also increases the hardness of the steel. However, an excessive carbon content can reduce the machinability and flexibility of the steel.

What Are the Types of Carbon Steels and Their Differences?

Carbon steels are divided into three main categories based on their carbon content:

Low Carbon Steels

Carbon Content: 0.05% – 0.30%

Characteristics:

Easily formable and weldable.

Low strength but flexible and durable.

Provides high impact resistance.

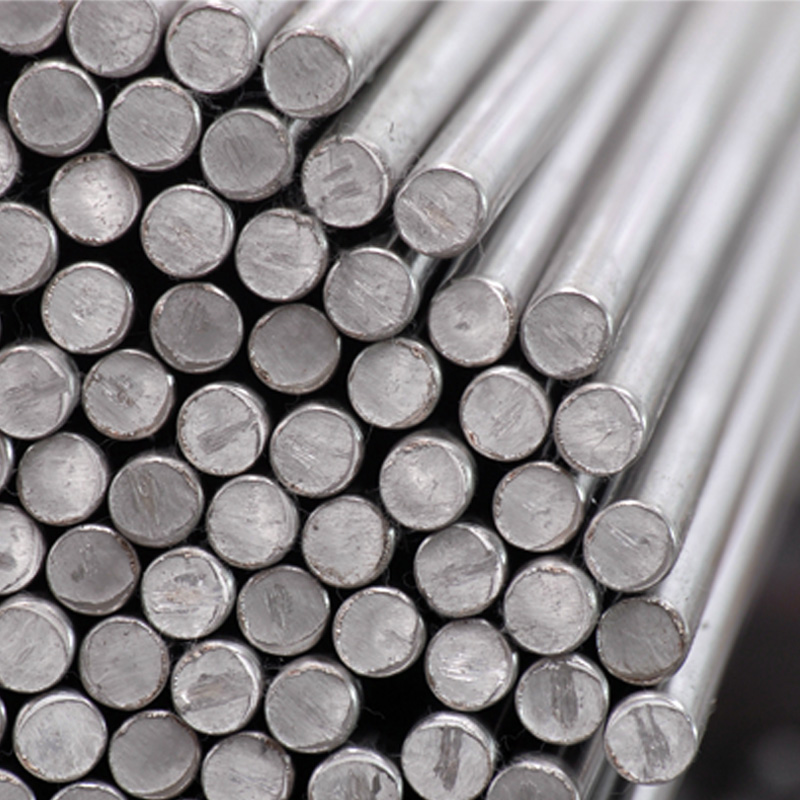

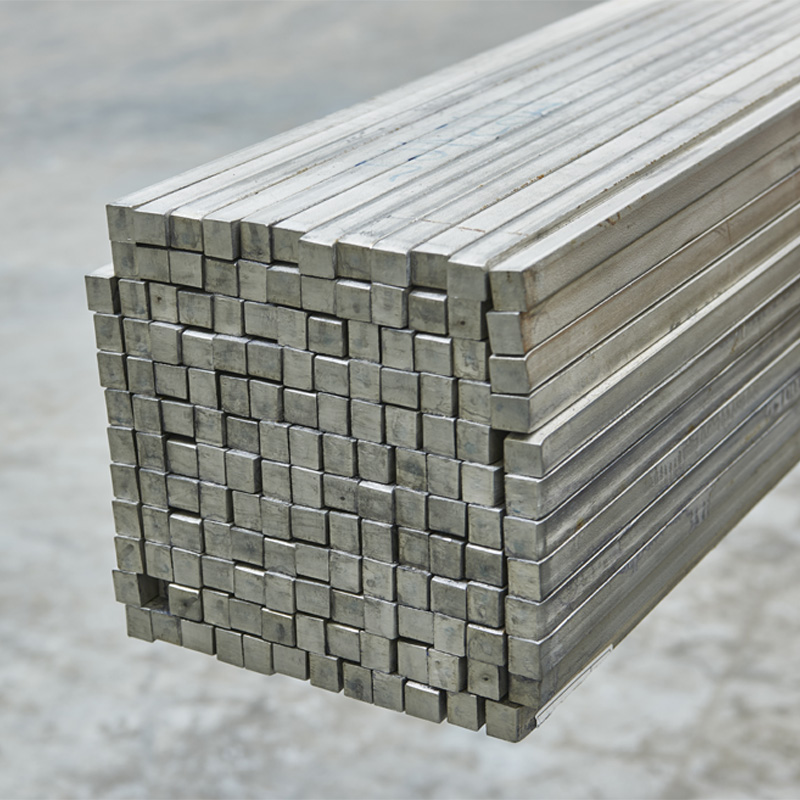

Applications: Automotive panels, pipes, and structural materials.

Medium Carbon Steels

Carbon Content: 0.30% – 0.60%

Characteristics:

Harder and more durable.

Resistant to high-weight loads.

Less flexible but can be customized with special heat treatment.

Applications: Machine parts, gears, shafts.

High Carbon Steels

Carbon Content: 0.60% and above

Characteristics:

Hard and durable but more brittle.

Has high wear resistance.

Applications: Cutting tools, springs, wires, and armored plates.

How Does Heat Treatment Change the Properties of Carbon Steels?

Heat treatment alters the microstructure of carbon steels to achieve desired properties. Processes include tempering, hardening, and annealing.

Tempering: Applied to reduce the brittleness of hardened steel.

Annealing: Makes steel softer and enhances formability.

Hardening: Provides high durability and hardness to carbon steels.

As a result of heat treatment, the strength, hardness, and flexibility ratios of carbon steels can be adjusted to desired levels.

What Are the Properties of Carbon Steels?

Carbon steel properties may vary based on the carbon content. Low carbon steels offer high strength and easy machinability, while high carbon steels are harder and more durable. Here are the general properties of carbon steels:

High Strength: Carbon steels are known for their high strength and are preferred in various fields, from construction to automotive.

Machinability: Steels with low carbon content are easily machinable, leading to wide usage in production.

Cost-Effectiveness: Carbon steels are more cost-effective compared to other steel types.

Durability: High carbon steels are highly resistant to wear and impact.

Are Carbon Steels Resistant to Corrosion?

Carbon steels generally have weak resistance to corrosion. This type of steel tends to rust in humid or acidic environments. The main reason is the absence of elements resistant to rust, such as chromium or nickel, in carbon steels. However, corrosion resistance can be enhanced through the following methods:

Coating: The risk of corrosion can be reduced by coating the surface of carbon steel with galvanizing, painting, or another protective layer.

Less Humid Environments: Using carbon steels in dry environments minimizes the likelihood of rusting.

Stainless Steel Alternative: In areas where corrosion resistance is critical, stainless or alloyed steels may be preferred.

What Are the Advantages of Low Carbon Steels?

The advantages of low carbon steels include:

Ease of Machinability: Their flexible structure makes it easier to shape them into special forms.

Economic Material: It is a low-cost material.

Weldability: Provides significant ease in welding processes.

Due to their properties, low carbon steels are preferred in building and infrastructure projects, pipelines, and automotive applications.

For What Purposes Are High Carbon Steels Preferred?

The hardness and strength properties of high carbon steels stand out in the following areas:

Cutting Tools: Meets the hardness requirements in applications such as knives, saws, and drill bits.

Armor and Protection: Offers high durability in ballistic armor.

Springs and Wire: Preferred in applications requiring mechanical strength.

What Should Be Considered During the Manufacture of Carbon Steels?

Carbon steels, due to their durability and economic advantages, are widely preferred in many industries. However, paying attention to certain criteria during the manufacture of carbon steels directly affects the quality and performance of the product. Here are the key points in carbon steel manufacturing:

1. Accurate Determination of Carbon Content

The most important feature of carbon steels is their carbon content. While low carbon steels are easily machinable, high carbon steels are used in applications requiring hardness and strength. During the manufacturing process, the carbon content should be selected according to the intended use of the steel.

2. Control of Manufacturing Temperature

Temperature control is a critical factor during the production of carbon steels. Excessive heating or cooling can adversely affect the structural properties of the steel. Especially in processes like annealing and hardening, the correct temperature range should be maintained.

3. Contribution of Alloying Elements

In some applications, alloying elements such as manganese, chromium, or molybdenum can be added to carbon steels to enhance durability and corrosion resistance. Proper adjustment of alloy ratios ensures desired properties.

4. Surface Treatments

Post-manufacture, the surfaces of carbon steels should be protected with coating, painting, or galvanizing. This provides both aesthetic appeal and reduces the risk of corrosion.

Low carbon steels are ideal for structural and general applications with their properties, while high carbon steels support special uses with their hardness and durability. Therefore, during the selection and processing of carbon steels, application needs and conditions should be carefully evaluated.

TR

TR