What is Steel Construction?

In today's construction industry, durability, flexibility, and cost-effectiveness have gained importance. At this point, steel construction structures stand out in both industrial and individual projects. Steel construction structures produced with modern construction techniques have become a widespread choice in various fields due to the numerous advantages they offer.

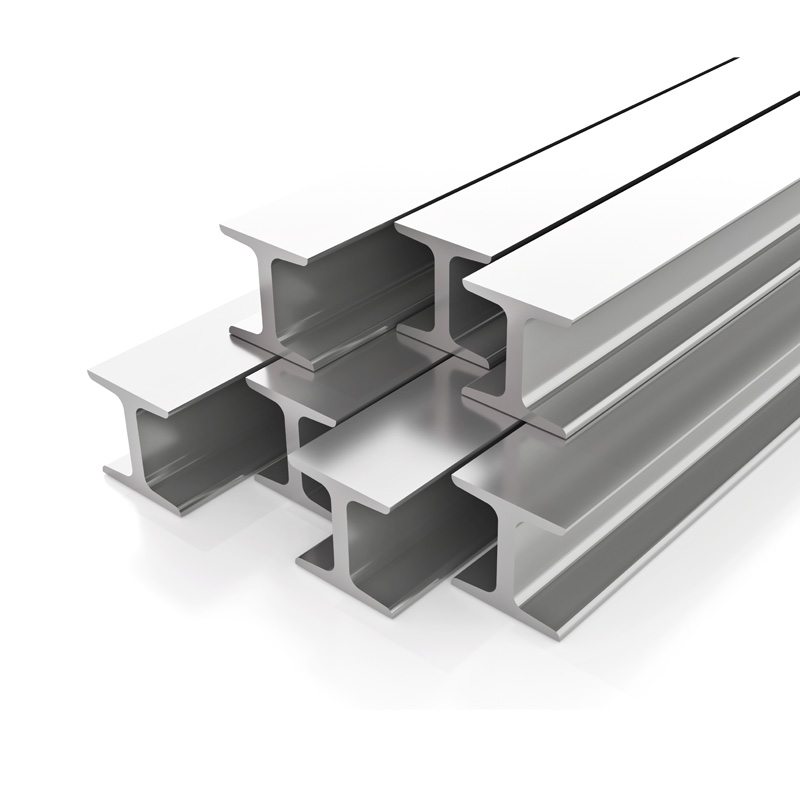

Steel construction is created by assembling steel elements that form the main framework or load-bearing systems of buildings and structures. Steel is preferred in this type of construction because, despite being lightweight, it has high strength. The steel elements used are assembled in desired shapes and sizes through special designs and calculations.

How Is Steel Construction Produced?

The production process of steel construction encompasses many stages and requires meticulous planning. These stages can be listed as follows:

- Design and Planning Initially, a design suitable for the purpose of the structure is created. At this stage, detailed projects are prepared using computer-aided design (CAD) software. Load calculations, carrier systems, and material selection are determined at this point.

- Material Selection The steel materials used for steel construction are generally high in tensile strength and corrosion-resistant. Materials selected according to quality standards are subjected to durability tests.

- Cutting and Shaping Steel elements are cut and shaped according to the project design. These processes are carried out precisely using laser cutting, plasma cutting, or CNC machines.

- Welding and Assembly The cut steel elements are combined to form the main structure. In this stage, welding techniques are used for joining. Careful work is required in this step to ensure the durability of the steel construction.

- Surface Protection Steel elements undergo galvanizing, painting, or coating processes to protect against corrosion and external influences. This step guarantees the long lifespan of the structure.

- On-Site Assembly Steel elements produced and pre-assembled at the factory are joined at the construction site. Techniques such as bolting or welding are used at this stage.

Why is Steel Construction Preferred?

Steel construction is frequently chosen in construction projects due to its various advantages.

- Lightweight and Strength Steel is a lightweight material despite its high strength. This allows for the use of less material in design and reduces the load on the foundation.

- Fast Construction Time Steel components manufactured in factories can be easily assembled on-site, shortening construction time and saving on time and costs.

- Flexibility and Design Freedom Steel construction offers more flexibility in architectural designs. Complex geometric shapes can easily be constructed using steel.

- Earthquake Resistance Due to its lightweight structure and elastic properties, steel construction buildings have a significant advantage in earthquake-prone areas.

- Easy Recycling Steel is a 100% recyclable material. This feature makes it an environmentally friendly construction solution.

What are the Benefits of Steel Construction?

- Durability: Thanks to the use of stainless steel and protective surface treatments, steel construction buildings maintain their durability for years.

- Low Maintenance Cost: Its durable structure minimizes the need for maintenance.

- Quick Installation: Offers ease of assembly on-site.

- Wide Application Areas: Can be used in various areas from industrial facilities to sports halls, from bridges to residences.

Where is Steel Construction Used?

The usage areas of steel construction are quite broad. These include:

- Industrial Buildings Steel construction is frequently preferred in industrial buildings such as factory buildings, warehouses, and hangars. Supported with large spans, these structures are constructed much more efficiently with steel components.

- Residential and Office Buildings In modern architecture, steel construction is used to create aesthetic and durable structures. It is especially preferred in projects where energy efficiency is a priority.

- Bridges and Tunnels The use of steel in load-bearing systems increases the durability of bridges and tunnels.

- Sports and Entertainment Facilities Steel construction is preferred in structures covering large areas such as stadiums, indoor sports halls, and exhibition centers.

- Infrastructure Projects Steel construction stands out in infrastructure projects like power plants, pipelines, and dams.

History of Steel Construction

Steel construction is a building technology that has become an important part of modern engineering and architecture. The use of steel in structures began in the 19th century and became widespread with the industrial revolution. The Bessemer Process, developed for the production of steel from iron, laid the foundation for steel construction. This method made steel both cheaper and more durable. The widespread use of steel construction in bridges, railways, and skyscrapers revolutionized engineering.

Today, steel construction is used not only in large building projects but also in a wide range of areas from industrial facilities to housing. The lightweight yet durable structure of steel has allowed modern architects to push the boundaries of creativity.

How Should Material Selection Be Made in Steel Structures?

Material selection in steel structures should be carefully planned according to the function of the structure, the loads it will be exposed to, and environmental conditions. Correct material selection enhances both the durability and economic efficiency of the structure. The fundamental factors to consider when selecting materials can be listed as follows:

- Strength: The strength values of the material to be used for steel construction must be capable of withstanding the loads imposed on the structure.

- Corrosion Resistance: Steel can be subject to corrosion in humid and acidic environments. Therefore, solutions such as stainless steel or galvanization should be preferred.

- Weldability: Welding is frequently used in the assembly of steel construction. The chosen material should have high weldability.

- Flexibility: To ensure the structure is resistant to earthquakes or other dynamic loads, flexible steel material should be preferred.

Correct material selection ensures not only the safety of the structure but also its longevity. In steel construction projects, professional support can be sought to achieve the most appropriate material selection.

Advantages of Steel Construction in Building Projects

Steel construction offers various advantages over traditional building methods. These advantages increase the preference for steel in construction projects. Here are the main advantages of steel construction:

- Lightweight and High Strength: Steel, while being a lightweight material, offers very high strength. This allows the structure to be more durable with less material.

- Fast Assembly: Steel construction elements can be prefabricated and quickly assembled on site. This allows the construction process to be completed in a much shorter time.

- Flexibility and Design Freedom: Steel construction is ideal for achieving creative and complex architectural designs. It is especially preferred in projects like skyscrapers and large sports complexes.

- Earthquake Resistance: Due to its flexible structure, steel construction is one of the best options for earthquake-resistant buildings.

- Long Life and Low Maintenance: Steel construction structures, if properly maintained, are very long-lasting and require minimal maintenance.

- Sustainability: Since steel is a recyclable material, it is environmentally friendly and adheres to the zero waste principle.

How is Steel Construction Assembly Done?

Steel construction assembly is a process carried out with detailed planning and expert teams. The assembly stages are generally as follows:

- Preparation and Planning:

- Before assembly, ground surveys are conducted and foundation construction is completed.

- All steel elements are checked for compliance with the project.

- Transporting Prefabricated Elements:

- Steel elements manufactured in the factory are transported to the site and prepared for assembly.

- Starting the Assembly:

- The process begins with the assembly of load-bearing columns and beams.

- Elements are placed with the help of a crane and secured with bolts.

- Welding and Securing:

- In addition to bolted connections, welding processes are carried out.

- It is very important to inspect all connection points at this stage.

- Final Inspections and Surface Protection:

- After assembly is completed, the overall structure is inspected.

- Painting or galvanizing processes may be applied for surface protection.

What Are the Types of Steel Construction?

Steel construction has various types suitable for different construction projects. These types include:

- Industrial Buildings:

- Structures that require large areas such as factories, warehouses, and logistics centers.

- Commercial Buildings:

- Shopping centers, hotels, and office buildings are in this category.

- Residential Buildings:

- Steel construction is widely used for prefabricated houses and villas.

- Bridges:

- Steel construction bridges are notable for their lightness and strength.

- Sports Facilities:

- Structures like stadiums and indoor sports halls that need to cover large areas.

- Tall Buildings:

- Skyscrapers have become possible thanks to the flexibility and durability provided by steel construction.

- Skyscrapers have become possible thanks to the flexibility and durability provided by steel construction.

Steel construction is an indispensable part of the modern construction industry with its versatile structure and the advantages it offers. This system, which can provide solutions for all types of projects, will continue to be preferred both today and in the future.

TR

TR

Box Profiles

Box Profiles Sheets

Sheets Pipes

Pipes Rolling Mill Products

Rolling Mill Products Construction Steels

Construction Steels Steel Meshes

Steel Meshes Construction Steel

Construction Steel Engineering Steels

Engineering Steels