Frequently preferred in the steel structure industry, IPE steel stands out for its durability, flexible structure, and the advantages it offers in various projects. It is commonly used in both modern construction technology and traditional projects.

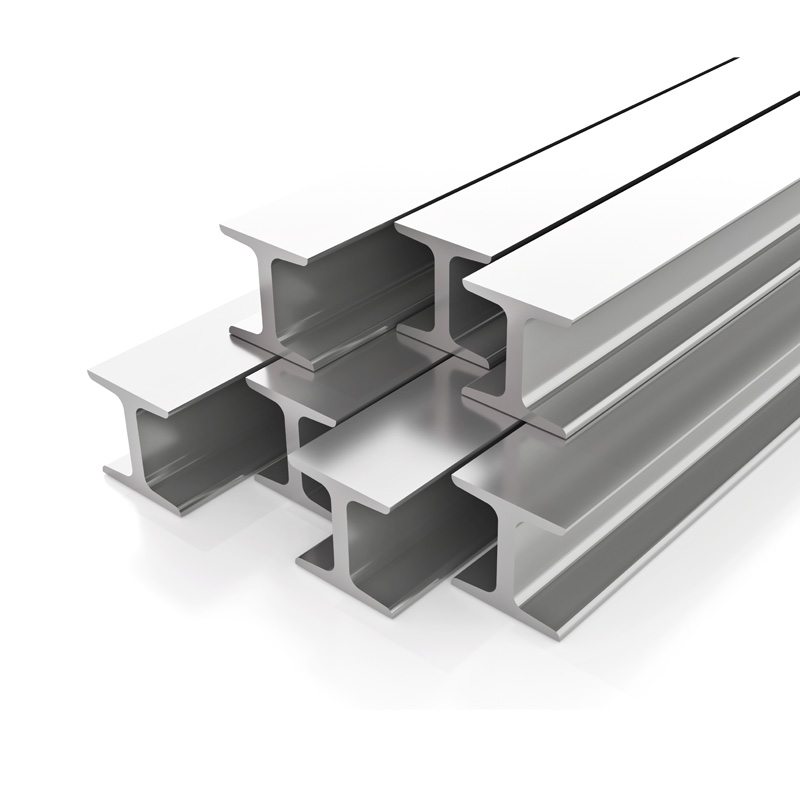

IPE iron is a structural profile commonly used in the construction sector, recognized by its "I" shaped cross-section. This term, originating from "I Profile European," refers to iron profiles manufactured in accordance with European standards. It is made from steel material and is prominent in projects requiring structural durability. IPE iron is particularly used to create systems capable of carrying more loads by reducing weight.

The production process of IPE beams is carried out using advanced technologies and precise control mechanisms in the steel industry. The process, which starts with steel production, consists of specific stages:

Steel Casting: Begins with melting the raw material in steel melting furnaces. At this stage, special alloys are added to the steel to enhance the material's physical properties.

Rolling: The melted steel takes the shape of an IPE profile through the rolling process. These procedures can be performed using either hot or cold rolling techniques.

Cutting and Shaping: Cuts are made to specific dimensions to create standard-sized profiles.

Quality Control: After production is completed, the IPE beam products are tested for compliance with international standards.

This process ensures that IPE beams are durable and high-quality materials.

What Are the Features of IPE Steel?

IPE steel has many technical and structural features. The standout features include:

High Strength: IPE steel can carry much more load relative to its weight, making it indispensable in structural projects.

Lightweight: Its low weight ratio allows for easy assembly and handling.

Standard Dimensions: IPE steel dimensions are produced according to certain standards, facilitating easier project design.

Long Lifespan: Its resistance to corrosion ensures structures have a long lifespan.

Easy Workability: Processes like cutting and welding can be easily applied.

Applications of IPE Steel

IPE steel has a wide range of applications. Some key areas include:

Industrial Structures: Frequently used in factories, warehouse structures, and industrial facilities. The durability provided by steel is important in these areas.

Bridges: Preferred in bridge constructions that require high load capacity.

Building Constructions: Used as a supporting system in both modern and traditional buildings.

Energy Sector: IPE steel is commonly preferred in infrastructure projects such as power poles and power plants.

Automotive and Machinery Industry: Used as support elements in machine chassis and automotive parts.

Standard Sizes of IPE Steel

IPE steel dimensions are offered in various standards to suit project needs. These dimensions are generally produced with high precision according to specific molds:

Height (h): Starts from 80 mm and can go up to 600 mm.

Width (b): Ranges from 46 mm to 220 mm.

Thickness (t): Can be between 3.8 mm and 21 mm.

Weight: Varies in kilograms depending on the dimensions of the profile.

These standards allow for the easy integration of IPE steel into different projects.

What Are the Technical Specifications of IPE Steel?

IPE steel profiles are sectional elements made from steel, commonly used in construction and industrial buildings. "IPE," short for "I Profile European," refers to a cross-section profile type that conforms to European standards. Because of their high strength, ease of transport, and flexible application areas, IPE steel holds a significant place in the modern construction industry.

Technical Specifications of IPE Profiles:

Cross-Section Shape: IPE steel is produced in a cross-sectional shape similar to the letter "I." This design allows for effective handling of both vertical and horizontal loads.

Material Strength: Produced from high-quality structural steel, IPE steel profiles offer durability and longevity, making them a preferred choice in the construction sector.

Size Options: IPE steel dimensions generally range from 80 mm to 600 mm, with production available in different lengths and cross-section sizes as needed.

Lightweight: The design of IPE profiles maintains high strength while being lightweight, reducing the overall weight of the structure and lowering the costs of the supporting system.

Compliance with Standards: Because IPE profiles are manufactured in accordance with European norms, they represent an important standard in terms of quality and reliability.

Use of IPE Profiles in the Construction Sector

IPE steel profiles are used as supporting elements in the construction sector. They are especially preferred in steel-structured buildings, bridges, roof systems, and column-beam structures.

Supporting Systems: Thanks to its high load-bearing capacity, IPE steel is used in building columns and beams. These structural elements effectively bear both static and dynamic loads.

Roof and Floor Applications: Due to their lightweight and durable structure, IPE profiles are used in roof systems and floor systems that span large openings.

Earthquake Resistance: IPE steel profiles made from steel material allow for the creation of structures that are more resistant to earthquakes due to their flexibility.

Ease of Installation: Prefabricated production and easy assembly allow for time and cost savings in construction projects.

Advantages of Using IPE Steel in Industrial Buildings

In industrial facilities, IPE steel profiles form the foundation of steel construction solutions. The advantages of using these profiles include:

Quick and Efficient Installation: Industrial buildings are typically projects that need to be constructed quickly. The prefabricated nature and light weight of IPE steel profiles meet this need.

High Load Capacity: IPE steel is a reliable supporting element for transporting heavy machinery and equipment in factory buildings.

Modular Structure: Since IPE steel profiles are compatible with modular structural systems, it is easier to expand or make changes to industrial buildings in the future.

Durability and Long Lifespan: In industrial buildings, materials that can withstand harsh conditions and have a long lifespan are important. IPE profiles meet this need.

Comparison of IPE and HEA/HIP Profiles: Technical Features

When compared to other steel profiles like HEA and HIP, IPE profiles have some advantages and disadvantages. Here are the important differences:

Cross-Sectional Area: HEA and HIP profiles have wider cross-sectional areas, enabling them to carry heavier loads. However, IPE steel profiles offer the advantage of being lightweight.

Load Capacity: HEA and HIP profiles are generally preferred in situations that require high moment capacity, while IPE steel profiles offer an ideal solution for medium-level loads.

Application Area: HEA steels are more often used in bridge construction and industrial facilities, while IPE profiles are generally used in residential and commercial building projects.

Cost: IPE steel offers a more economical option compared to HEA and HIP profiles.

IPE Steel Cross-Section Measures and Load-Bearing Capacity

IPE steel dimensions vary depending on the projects. Different sizes provide different advantages in terms of load-bearing capacity and durability.

Cross-Section Measures:

IPE 80: 80 mm height, suitable for light loads.

IPE 200: 200 mm height, offers medium-level load capacity.

IPE 600: 600 mm height, has high load capacity.

Load Capacities: IPE steel profiles have different load-bearing capacities depending on their shape and size. This capacity depends on the profile's width, height, and material thickness.

Supported by Tables: Load capacities for each IPE steel dimension can be detailed through tables. These tables serve as an important guide in construction and industrial projects.

IPE steel is an indispensable material in construction and industrial projects due to its IPE steel dimensions and technical features. With both its durability and economic advantages, these profiles continue to form the foundation of the modern construction industry.

TR

TR