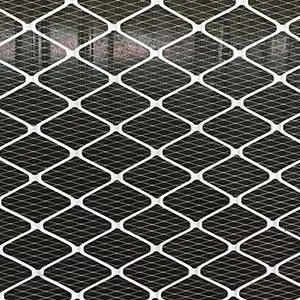

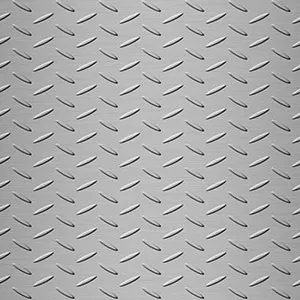

Pricing of checker plate steel varies widely, influenced by factors ranging from production costs to exchange rates. Thickness, size, and pattern frequency are key elements that directly affect unit prices. The balance of supply and demand, fluctuations in the steel market, and global economic conditions also play significant roles in determining these prices. As the required quantity increases, the cost per unit generally becomes more advantageous. Therefore, checker plate steel prices should be regularly monitored for both small-scale projects and large industrial needs. Deha Metal closely observes market conditions to offer its customers current and competitive rates.

Current Prices of Checkered Patterned Steel

Current checkered patterned steel prices are frequently updated based on various factors, from steel production costs to logistics expenses. Especially during periods of intense steel raw material imports, fluctuations in exchange rates can quickly reflect on costs. Additionally, increases in energy costs and changes in global steel demand are primary factors affecting the prices of these products.

Checkered patterned steels are typically chosen for areas requiring a non-slip surface. Hence, they have wide applications in construction, automotive, and industrial platforms. Deha Metal offers checker plates in different thicknesses and sizes, providing solutions suitable for every project. You can contact the company to learn current prices and get special offers tailored to your projects.

Furthermore, due to the competitive nature of the market, there may occasionally be advantageous campaigns and bulk purchase discounts. These discounts provide significant cost advantages, especially for businesses requiring a large number of checkered pattern steel. Deha Metal prioritizes customer satisfaction by setting the most suitable pricing policies for both large-scale projects and individual purchases.

How are Checker Plate Steel Prices Calculated?

Checker plate steel prices are generally determined by a weight-based calculation method. Factors such as the quality of the steel used, additional processes forming the pattern, and thickness shape this cost. The following basic formula can be used:

Price = Steel Weight (kg) × Unit Price (TL/kg) + Additional Process Costs (if any)

- Steel Weight: Calculated using the thickness, width, and length of the steel. The density of steel is approximately 7.85 g/cm³, so this value is converted to kilograms based on the steel’s dimensions.

- Unit Price: Refers to the current market cost per kilogram of steel raw material. Exchange rates, taxes, and the supply-demand balance in the international steel market affect this figure.

- Additional Process Costs: Additional processes such as cutting, welding, or protective coating may be required for some projects. In such cases, labor and material charges are added to the total cost.

For example, if we take a checker plate steel with a thickness of 2 mm and dimensions of 1000 mm x 2000 mm as weighing 31.4 kg (example calculation), with a unit price of 25 TL/kg:

Price = 31.4 × 25 = 785 TL

If no additional processing is required, this figure would give the cost of a single steel plate used in your project. In bulk purchases, the cost per unit becomes more attractive.

How are Checker Plate Steel Prices Determined?

Checker plate steel prices are determined by a combination of internal and external factors. The main influencing factors in price formation are outlined below:

- Raw Material Supply: Changes in the supply of iron ore and other alloys used in steel production can cause prices to rise or fall. An increase in global steel demand also raises raw material costs.

- Exchange Rates: Particularly when imported raw materials are used, fluctuations in exchange rates can cause rapid increases or decreases in production costs.

- Production and Energy Costs: Processes such as pressing, rolling, or laser cutting used to create checker patterns are additional cost elements. Increases in energy prices directly affect production costs.

- Transport and Logistics: The distance the steel is to be transported, transportation methods, and fuel costs can raise the final sale price. Especially for large or heavy steels, transport costs become a significant item.

- Supply-Demand Balance: When demand for checker plate steel increases in the market, prices may rise in the short term. When there is an excess supply, prices may remain more stable or lower due to competition.

- Competitive Offers: Manufacturers' campaigns, seasonal discounts, or project-based special agreements can directly affect the checkered patterned steel price.

Deha Metal always adopts a transparent approach regarding checker plate steel prices. Its expert team provides special price proposals according to the thickness, dimensions, and pattern intensity needed for your project. Additionally, by managing its stock efficiently, it responds quickly to demand and uses competitive conditions to the advantage of its customers.

Thus, it helps you realize your projects with both quality and cost-effective solutions. When you want to procure the checker plate steel needed for your projects at an affordable price and receive advantageous offers according to current market conditions, simply contact Deha Metal’s experienced team.

TR

TR