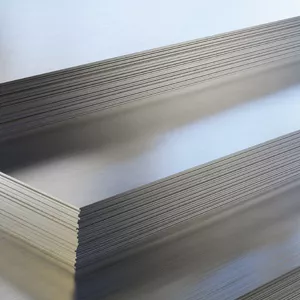

Sheet metal prices constantly fluctuate due to many variables, ranging from costs in raw material supply processes to exchange rates and energy expenses. Especially the supply-demand balance in the steel market has a decisive effect on prices. While unit costs are generally more advantageous for businesses making bulk purchases, seasonal campaigns or special discounts can also play a significant role in sheet metal prices. At Deha Metal, we prioritize offering competitive figures to our customers and closely follow current market conditions to provide the most suitable sheet metal prices.

Current Sheet Metal Prices

Sheet metals are one of the cornerstones of the steel industry and are used in many different fields. This wide range of uses leads to a significant increase in market demand and dynamic pricing. Factors such as fluctuations in exchange rates, global challenges in raw material supply, or rising energy costs directly affect current sheet metal prices.

Especially galvanized sheet prices can vary depending on the thickness of the coating and the amount of zinc used. Higher coating thickness provides better corrosion resistance but can increase costs. Deha Metal delivers sheet metals in different thicknesses and sizes to its customers within the framework of an up-to-date pricing policy, aiming to offer both quality materials and economical solutions. Taking into account the needs of each project, we provide flexible pricing and fast delivery options for both small-scale and large-scale projects.

In an environment where market conditions are constantly changing, we regularly analyze and manage the supply chain in the most efficient way to ensure our customers have access to the most accurate price information. This allows you to continue your projects without compromising on quality standards while gaining a cost advantage.

How Are Sheet Metal Prices Calculated?

Sheet metal prices are generally calculated based on the weight of the sheet, the unit price, and any additional coating costs. Our company, Deha Metal, offers a detailed cost analysis tailored to the needs of each project. The basic formula used in price calculation is as follows:

Price = Sheet Weight (kg) × Unit Price (TL/kg) + Additional Coating Cost (TL)

Sheet Weight:

Calculated considering the thickness, width, and length of the sheet. The average density of steel is assumed to be 7.85 g/cm³. For example, the weight of a sheet with a thickness of 1 mm and dimensions of 1,000 mm × 2,000 mm is approximately calculated as follows:

(1,000 mm × 2,000 mm × 1 mm × 7.85) / 1,000,000 ≈ 15.7 kg

Unit Price:

The price per kilogram of steel under current market conditions. This value is directly affected by exchange rates, energy costs, and the global supply-demand situation.

Additional Coating Cost:

Especially concerning galvanized sheet prices, the thickness of the material used for zinc coating and the process can create extra costs.

Example Calculation:

Weight: 15.7 kg

Unit Price: 28 TL/kg

Coating Cost: 20 TL

Price = (15.7 × 28) + 20 = 439.6 + 20 = 459.6 TL

This calculation method can be adapted for sheet metals of different thicknesses and sizes. At Deha Metal, we adopt a meticulous approach to derive the most accurate cost according to the features of each project.

How Are Sheet Metal Prices Determined?

Sheet metal prices are formed by a combination of many market factors. At Deha Metal, the main variables we consider when determining these prices are as follows:

- Raw Material Costs:

Changes in the prices of iron ore, scrap steel, and other alloys used in the production of steel directly affect sheet metal prices. Global demand increases or restrictions determine raw material costs. - Energy and Labor Costs:

The price of electricity, natural gas, and other energy sources used in the production process affects the final product. Additionally, increases in labor costs can lead to a rise in unit prices. - Exchange Rates:

When imported raw materials or equipment are used, fluctuations in exchange rates can cause noticeable changes in prices. - Supply-Demand Balance:

Increases in the demand for sheet metal in the market can quickly raise prices. Conversely, when there is an excess supply, increased competition can temporarily drive prices down. - Coating Type and Thickness:

Galvanized sheet prices vary depending on the thickness of the coating and the amount of zinc used. Thicker coatings provide higher protection but increase costs. - Logistic and Storage Costs:

The transportation methods and storage conditions used in the shipment of products are also reflected in prices. These costs become more apparent, especially in large-volume purchases.

Deha Metal aims to offer its customers transparent and up-to-date pricing by analyzing all these factors in detail. According to the scale and characteristics of your project, we are with you with solutions that will achieve the best price-performance balance. Thanks to our extensive industry experience and wide supply network, we quickly and reliably meet your sheet metal needs, helping you optimize your costs.

Sheet metal prices are affected by both global markets and local dynamics. As a company, our aim is to provide continuous support to our customers, ensuring maximum satisfaction in terms of cost, quality, and delivery times. You can contact us anytime to get the latest price information, take advantage of our special discounts, and acquire sheet metal solutions for your projects. With Deha Metal's quality and expertise, adding value to your projects and offering you the most competitive conditions is our top priority.

TR

TR