What is Roll Slitting?

Roll slitting is the process of converting wide metal coils (sheet, steel, aluminum, etc.) into narrow strips or slit rolls of specific widths. This method is a production technique commonly used in industries such as metal processing, construction, automotive, white goods, and furniture.

How Does the Roll Slitting Process Work?

Placing the Coil

A large and wide metal coil is placed into the slitting machine.

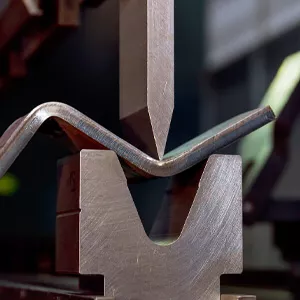

Slitting Machine

The slitting machine uses knives set for the coil’s width to cut the metal sheet into strips of the desired width.

Forming into Strips

The cut strips are wound into separate rolls and prepared for subsequent processes.

What are the Advantages of Roll Slitting?

Production to Specification

Slitting is done to the measurements specified by the customer and according to needs.

Precision

The slitting process is performed with high precision, reducing material loss and error rates.

Efficiency

Slitting metal coils speeds up the production process and reduces costs.

Diversity

Materials of different thicknesses and widths can be easily processed.

It is possible to design roll slitting processes according to weight, width, diameter, or material quality desired by users. Especially in slitting roll processes, the procedure of unwinding a sheet product in a roll form with specific widths into narrow strips is called roll slitting.

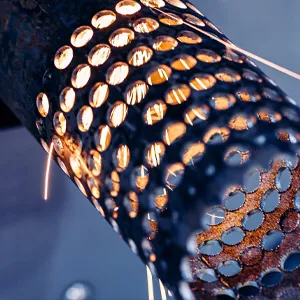

Roll slitting and laser cutting are methods frequently used in the metal processing sector. Roll slitting cuts wide coils into strips of the desired width, while laser cutting is chosen for precise cuts. Both methods optimize industrial production processes by ensuring high accuracy and efficiency.

Roll storage turnstiles generally facilitate the transfer of the coil near the line section, reducing the loading time of the roll.

With ground-level coil loading operations, the coil is either taken from the channel where vehicles are kept ready or transferred quickly using a crane to the roll-opening rollers.

Roll Unwinding Applications

Roll unwinding products ensure that the edge of the product to be unwound during a certain evaluation phase is fed. Upper pressure rollers powered by motors prevent the sheet product from unwinding uncontrollably.

Deha Metal manufactures materials at the quality and dimensions requested by customers and delivers them at affordable prices through its expert staff in sheet-related matters, creating them in the most precise measurements requested.

During roll slitting processes, periodic checks are made by an expert team. After the control and cutting processes, final checks are conducted, and with the strapping method, the roll slitting processes transition to the packaging process of storage, where labeling is ensured. Thus, roll sheets are made ready for delivery to users. Products obtained from slitting rolls are generally used in various fields such as decor, automotive, furniture, electronics, and electrical companies.

Products passing through steel slitting equipment can generally be cut to desired dimensions, weights, and lengths. These roll sheets, easy to transport and packaged to be resistant to scratches, are sent to users and customers.

Addressing Deha Metal Customer Inquiries

Users can exchange information through communication channels if they have any questions or concerns regarding roll slitting processes.

Contact and Supply Processes

For individual or corporate customers who want to make requests related to their processes or place orders, they can reach out through established email addresses or websites, or 24/7 through communication channels to relay all their wishes, requests, complaints, and orders.

TR

TR