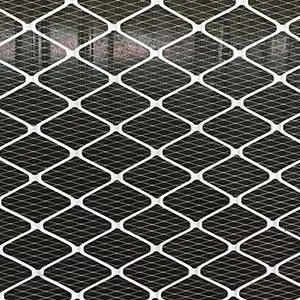

Tear pattern sheet prices can vary depending on the thickness, dimensions, and market conditions. Fluctuations in exchange rates, prices of steel raw materials, and energy costs can also cause variations in sheet prices. The quantity to be purchased and demand also play a decisive role in tear pattern sheet prices. Particularly in bulk purchases, the cost per unit often becomes more advantageous. Deha Metal aims to offer the most current and competitive pricing for these products, considering the prevailing market conditions.

Current Tear Pattern Sheet Prices

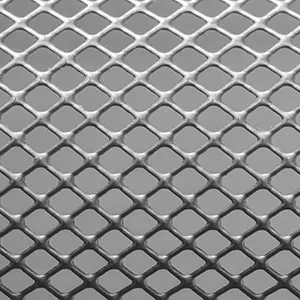

Tear pattern sheets offer a non-slip surface feature and aesthetic appearance. When it comes to pricing, technical details such as thickness and the depth of the pattern stand out. Thicker sheets may increase in price due to the need for more material. Additionally, other cost factors like processes applied in production, labor costs, and logistics expenses directly affect current tear pattern sheet prices. Deha Metal offers a wide range, presenting different thickness and size options suitable for every budget with its customer-focused approach.

How Are Tear Pattern Sheet Prices Calculated?

Tear pattern sheet prices are typically calculated based on the weight of the sheet and the unit price. The following formula is a fundamental method used in determining this cost:

Price = Sheet Weight (kg) × Unit Price (TL/kg)

- Sheet Weight: Calculated using the sheet's thickness, width, and length. For instance, the weight of a 2 mm thick and 1000×2000 mm tear pattern sheet is determined as follows:

(1000 mm × 2000 mm × 2 mm × 7.85 g/cm³) / 1000 = 31.4 kg - Unit Price: Based on the steel price per kilogram and pattern processing cost, as determined by market conditions.

In the final calculation, additional costs such as shipping fees or extra surface treatments may be included in the total cost of the sheet. Deha Metal considers these factors to perform the most accurate price analysis for your projects.

How Are Tear Pattern Sheet Prices Determined?

Tear pattern sheet prices result from a combination of various external and internal factors. Fluctuations in exchange rates, interruptions in raw material supply, or changes in the supply-demand balance are key determinants. Additionally, the condition of the sector where the sheet is demanded and competitive conditions also contribute to price formation. Factors such as the manufacturers' inventory management, the efficiency of the technology used, and energy costs also affect pricing.

Deha Metal prioritizes customer satisfaction regarding tear pattern sheet prices and offers affordable solutions by conducting competitive market analyses. It provides the necessary information for you to make the right decisions for the most suitable thickness, size, and pattern options for your project needs. This way, you can protect your budget and securely obtain materials that will add value to your project.

TR

TR