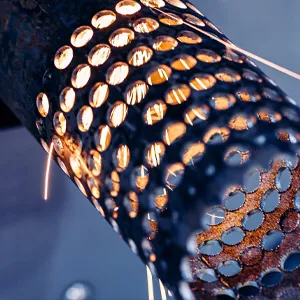

Pipe laser cutting technology holds a significant place for those seeking precision and speed in industrial production processes. Today, the opportunities offered by laser technology in metal processing are widely used in the cutting of pipes and profiles.

What is Pipe Laser Cutting?

Pipe laser cutting is the process of cutting pipe and profile materials using laser technology. This method allows pipes made of metal, aluminum, stainless steel, and other materials to be cut into desired dimensions and shapes. The laser pipe cutting machine works with high precision during this process and can easily accomplish complex designs. Especially in industrial production processes, material waste is minimized, and production efficiency is increased thanks to pipe laser cutting technology.

How is Pipe Laser Cutting Done?

The pipe laser cutting process is performed with specially designed laser pipe cutting machines. The process is applied through the following steps:

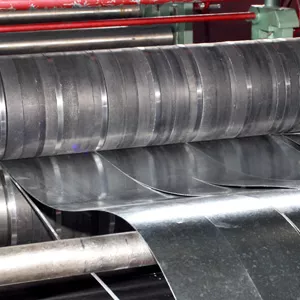

- Material Preparation: The pipe or profile to be cut is placed on the platform of the laser cutting machine. The material is automatically aligned and secured.

- Design and Programming: The shape to be cut is prepared in computer-aided design (CAD) programs. Then this design is transferred to the laser pipe cutting machine.

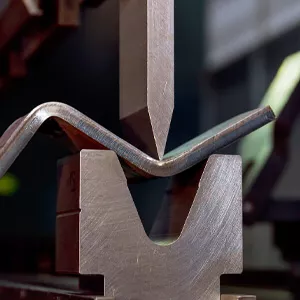

- Cutting Process: The machine starts cutting the pipe using a high-intensity laser beam. The laser beam focuses on the surface of the pipe, causing the material to vaporize or melt.

- Cooling and Cleaning: After the cutting process is completed, the surface of the pipe is cooled and cleaned. Thus, the material becomes ready for use.

Laser pipe cutting machines offer very high precision during the cutting process. This minimizes cutting errors and prevents time loss.

Where is Pipe Laser Cutting Used?

Pipe laser cutting technology has a wide area of application in many sectors. Here are some areas where this technology is used:

- Furniture and Decoration: Laser technology is preferred for the cutting of metal pipes used in modern furniture designs. It provides an advantage especially when making special aesthetic designs with laser pipe cutting.

- Construction and Building: Steel construction structures can be cut in desired dimensions and angles with a pipe laser cutting machine. This increases the strength and aesthetics of the structures.

- Automotive Industry: Laser cutting technology is used in the production of chassis and other metal parts of vehicles. Speed and precision provide a great advantage in the automotive sector.

- Machine and Equipment Manufacturing: Laser pipe cutting technology is frequently used in the production of industrial machine parts. This method is particularly effective for complex designs.

- Aerospace and Defense Industry: Pipe laser cutting technology is preferred for parts requiring high precision and reliability.

What are the Advantages of Pipe Laser Cutting Technology?

Pipe laser cutting technology offers many advantages. Here are some of these advantages:

- High Precision: Laser pipe cutting machines can make flawless cuts even in precisions below a millimeter.

- Speed and Efficiency: Laser technology is much faster compared to manual cutting methods. This accelerates production processes and reduces costs.

- Complex Designs: Laser cutting machines can cut complex shapes and detailed designs effortlessly.

- Reduces Material Waste: There is minimal material loss during cutting, which provides a cost advantage.

- Low Maintenance Cost: Modern laser pipe cutting machines are durable and long-lasting, offering cost advantages in the long run.

- Eco-Friendly: Laser cutting technology consumes less energy compared to other methods and is less harmful to the environment.

How to Choose the Most Suitable Machine for Pipe Laser Cutting?

When selecting a pipe laser cutting machine, there are several important points to consider. Here are the factors to take into account during this process:

- Identify Your Cutting Needs: You should choose a machine based on the type and thickness of the materials you will cut. For instance, machines with different features may be required for cutting stainless steel or aluminum.

- Cutting Capacity: Determine the cutting capacity of the machine according to your work volume. Higher capacity machines should be preferred for larger work volumes.

- Precision and Speed: Cutting precision and speed are crucial for the efficiency of your production processes. Machines offering high precision save cost and time.

- Technology and Software: Modern laser pipe cutting machines are equipped with advanced software and automation features. Such machines facilitate your work processes.

- Cost and Maintenance: Evaluate the maintenance costs as well as the initial purchase cost of the machine. Machines that are long-lasting and require low maintenance could be a more economic choice.

- Warranty and Technical Support: Review the warranty period and technical support services offered by the manufacturer. A strong technical support network helps resolve any issues you may encounter in your work processes quickly.

In Which Industries is Pipe Laser Cutting Most Preferred?

Pipe laser cutting technology has become very significant in industrial production in recent years. It is preferred in many sectors due to its advantages like high precision, rapid production, and material savings. It is widely used especially in the following industries:

- Automotive Industry: Pipe laser cutting technology is used for the precise cutting of various pipe components in the automotive sector. It is crucial in parts like exhaust systems, chassis structures, and steering mechanisms.

- Furniture and Decoration Industry: Pipe laser cutting allows the creation of complex patterns in modern furniture designs. It also provides elegant and refined details in decorative objects.

- Construction and Building Industry: It is used for cutting steel structural elements and pipe profiles in the construction and building industry. This technology is especially common in steel construction projects.

- Medical Industry: A pipe laser cutting machine is essential in the production of medical equipment and devices. It stands out in the production of medical devices requiring precise cutting.

- Defense Industry: Pipe laser cutting is an indispensable technology for the defense industry, which requires high precision and quality production.

How Long Does the Pipe Laser Cutting Process Take?

The duration of the pipe laser cutting process can vary depending on various factors. These factors include the material, diameter, thickness, and cutting pattern of the pipe. In general, laser pipe cutting machines offer faster processing compared to traditional methods.

- Material and Thickness: Cutting speeds vary for different materials such as steel, aluminum, or copper. Thinner materials are cut faster, while thicker pipes may take more time.

- Cutting Pattern: Simple geometric shapes are cut in less time, while complex patterns require a longer process.

- Machine Performance: The power and precision of the pipe laser cutting machine directly affect the processing time. Modern machines can complete multiple pipe pieces per minute.

What Should be Considered When Buying a Pipe Laser Cutting Machine?

The main factors to consider when selecting a laser pipe cutting machine can be summarized as follows:

- Cutting Capacity: The machine should be able to cut pipes of various diameters and thicknesses. Therefore, a machine that suits the production needs of your business should be chosen.

- Precision: The precision level of the pipe laser cutting machine is very important. Machines with high precision should be selected for projects requiring very fine cuts and complex designs.

- Energy Efficiency: Long-term cost savings can be achieved by choosing machines with low energy consumption and high efficiency.

- Ease of Use: Machines that offer a user-friendly interface, which operators can use easily, should be preferred.

- Service and Technical Support: Technical support and service facilities after machine sale are also important. Therefore, buying from a reliable seller is necessary.

- Software and Technology: Machines supporting advanced software and integrated with automation systems offer more effective solutions.

Common Problems and Solutions in Pipe Laser Cutting Machines

During the use of a pipe laser cutting machine, some common problems may be encountered. These problems and their solutions can be summarized as follows:

- Decrease in Cutting Quality:

- Problem: Burn marks or burrs on the cutting edges may occur during the laser cutting process.

- Solution: The machine lenses should be cleaned, and focus settings should be checked. Appropriate power settings should be made.

- Machine Failures:

- Problem: Interruptions may occur due to electrical or mechanical failures.

- Solution: Machine maintenance should be done regularly, and part replacements should be made on time.

- Materials Not Being Properly Processed:

- Problem: Extremely thick pipes may cause problems during cutting.

- Solution: Suitable material should be chosen based on the machine capacity.

- Software Errors:

- Problem: Software errors may occur during the upload of cutting designs.

- Solution: Software updates should be made regularly.

Which Laser Cutting Machine is Suitable for Different Diameter and Thickness Pipes?

Selecting a suitable laser pipe cutting machine for processing pipes of different diameters and thicknesses is critical.

- Universal Machines: Universal machines that can cut pipes of various sizes and thicknesses offer versatile working capabilities.

- Fiber Laser Cutting Machines: Fiber laser cutting machines are ideal for projects requiring high precision and speed. They can easily process pipes of different diameters.

- CO2 Laser Cutting Machines: CO2 laser machines can be preferred for cutting thicker pipes. These machines generally perform better in very thick materials.

Pipe laser cutting technology stands out as a solution partner in many areas of industrial production. By choosing the right machine and applying proper maintenance, you can increase your production efficiency and achieve higher quality results.

TR

TR