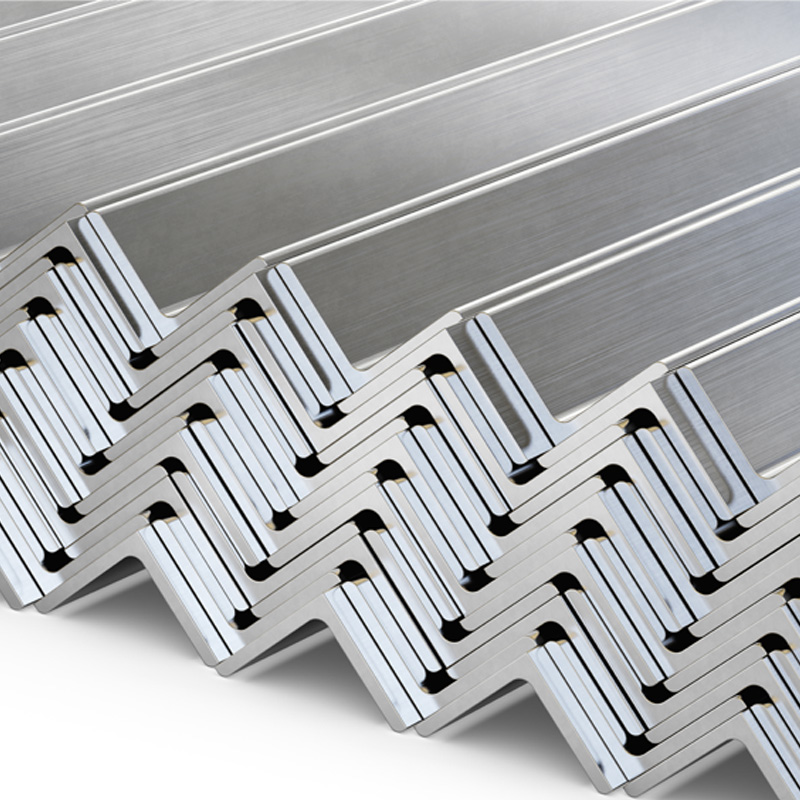

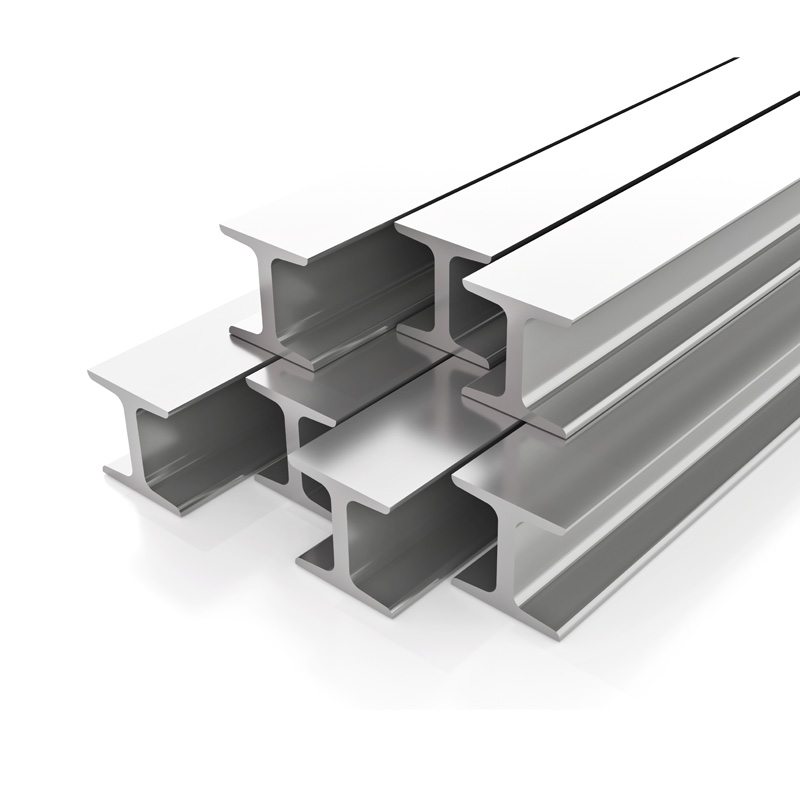

Angle irons are profile types frequently used in the construction sector, providing durability and strength. They are typically made from steel, aluminum, or stainless steel and come in various sections. Angle irons are preferred especially in corner joints to increase load-bearing capacity, strengthen connections, and provide an aesthetic appearance. They are widely used in construction, furniture, automotive, and machinery industries. They offer reliable solutions in projects with both their lightweight structures and durable features.

Angle bracket is a structural component that forms a right angle and is typically made from durable materials like metal or plastic. While metals such as steel, aluminum, or stainless steel are often preferred, plastic or composite angle brackets may be used in lightweight construction projects. Its shape usually resembles the letters "L" or "T," which increases durability and stability. Angle brackets are commonly used in applications like construction and furniture assembly to support structures, join parts, or correct corners.

The areas of use for angle brackets are quite broad. Here are the main areas:

Construction Sector

Angle brackets are widely used to ensure and support the structural balance of buildings. They play an important role especially in steel structures. They are also preferred as support elements in reinforced concrete structures.

Furniture and Decoration

Angle brackets are frequently used in furniture assembly, shelving systems, and cabinet making. These elements, which stand out for both durability and aesthetics, offer various solutions for furniture.

Industry and Manufacturing

In factory environments, angle brackets are used for applications like production line support or the assembly of machines. Metal angle brackets are a durable option suitable for such intensive use.

Commercial Areas

Angle brackets are crucial in warehouse shelving systems, exhibition stands, and the interior fixtures of commercial buildings. Particularly durable steel angle brackets are preferred.

What Materials Are Angles Made Of?

The materials used in the production of angles vary according to the needs of the area in which they will be used. Here are the commonly preferred materials:

Steel: The most common angle material, steel offers durability and longevity. Steel angles are generally used in heavy construction applications.

Aluminum: A lighter yet durable alternative, aluminum is preferred in applications not as dense as steel.

Stainless Steel: Stainless steel angles are ideal for use in environments exposed to moisture or corrosion.

Plastic: With its lightweight structure, plastic angles are used in decorative or light support applications.

Composite Materials: Preferred in next-generation applications, composite materials offer a combination of lightness and durability.

Are There Different Types of Angles?

Yes, there are many different types of angles designed according to needs. Here are the main types of angles:

Standard Angles: These angles are generally "L" shaped and used for simple joining or support.

Adjustable Angles: Adjustable designs allow for assembly in different sizes and angles.

Decorative Angles: These types offer both aesthetic and functional solutions. They are preferred in furniture and interior decoration applications.

T-Angles: Shaped like a "T", these angles are used to join vertical and horizontal elements.

Corner Support Angles: These angles are used to increase the stability of corner points.

What Are the Benefits of Angles?

The benefits of angles may need to be examined in general. Using angles ensures that lines are both more regular and sturdier. They are typically used at corners and centers, which are more exposed to impacts and mishaps. Therefore, using them helps prevent breaking in the area against a possible impact. Thus, they should be preferred.

The benefits of stainless angles, in other words, those made of stainless steel, include their longevity. Angles typically suffer from rusting. Although the use of these products provides benefits similar to others, their stainless feature makes them more durable. Rusting is not seen for long periods in the area of use, and breakage does not occur.

Why Do Angles Rust?

When having an angle made, it is essential to use materials known to be produced by a quality and reputable brand. As angles are materials made of iron, they rust in humid and damp environments. For such environments, the use of plastic angles or stainless steel angles is recommended.

Previously, the area where an iron angle was made might have experienced rusting. In such cases, the angle can be removed and replaced with a new one. If this is not preferred, the plaster of the rusted areas can be scraped. After this process, an anti-rust treatment should be applied. Once the anti-rust treatment dries, the plastering process can be done again.

Angle Dimensions

Angles are manufactured as equal-sided angles or unequal-sided angles. These can be defined as being produced with equal or unequal ends. The dimensions of equal-sided angles are determined according to the EN10056-1: 1998 standard. The tolerance values are according to EN10056-1: 1994 standards. The surface condition is as per the EN10163-3 2004 standard.

The length, tolerance values, and surface condition standards of unequal-sided angles are the same. Examples of dimensions can be given here. Equal-sided angles can be L 25x25x3, L 25x25x4, L 250x250x35. In unequal-sided angles, dimensions can be L 100x65x7, L 100x65x8, L 200x100x15.

What Safety Measures Should Be Taken Regarding the Use of Angles?

Safety in the use of angles is an important aspect to be considered during both production and installation.

Correct Material Selection: The angles used must meet the durability and strength requirements.

Use of Equipment: The tools and machines used during the installation should be regularly maintained and used correctly.

Personal Protective Equipment: Protective equipment such as gloves, glasses, and helmets must be used during the installation.

Training: Personnel installing angles should have comprehensive safety training.

Periodic Inspections: Installed angles should be regularly inspected, and maintenance should be done if necessary.

Angle manufacturers and users must pay attention to the above safety measures to ensure building safety and protect the health of workers.

What Should Angle Manufacturers Pay Attention To?

Angle manufacturers need to consider numerous factors to offer quality and durable products. The quality of the raw materials used in the production process determines the durability and lifespan of the products.

In addition, angle manufacturers should produce in accordance with standards and closely follow technological innovations. Especially if you are working with materials like steel, aluminum, and stainless steel, it's crucial to carefully manage the material supply chain. Any defects in raw materials can reduce the quality of the angles produced.

Moreover, in angle production, customer demands and expectations should be considered. Offering designs suitable for specific applications among the various types can provide a competitive advantage. Additionally, fulfilling environmental responsibilities and engaging in sustainable production are critical factors for both the company's reputation and its future.

TR

TR