Developing industrial technologies and precise processing requirements necessitate the versatile use of metal types. In this context, free cutting steels stand out, particularly in applications where easy machinability and precision are needed. The special mechanical properties of free cutting steels , their various alloys, and wide application areas have made them an indispensable part of modern manufacturing processes.

Free-cutting steel is a type of steel specially developed to provide high machinability in machining processes. Additives such as sulfur, phosphorus, or lead in its composition facilitate chip breaking and increase cutting speed. This results in smooth surfaces and reduced tool wear. Free-cutting steel is commonly preferred in the automotive, machinery, and electrical-electronics sectors for the production of precise and small parts like screws, nuts, and shafts. This steel, offering medium strength, provides time and cost advantages, especially in mass production.

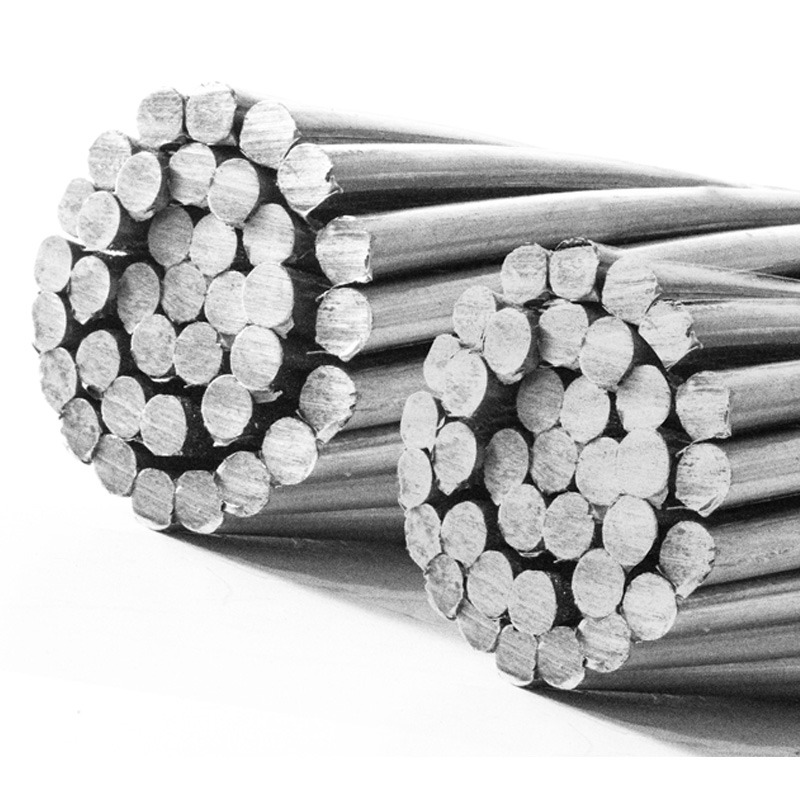

Free machining steels, as the name suggests, are a type of steel designed for use in automatic lathes. One of the main characteristics of these steels is their extremely easy machinability. This feature accelerates chip formation and optimizes production processes.

The main application areas of free machining steel are as follows:

Production of Small Parts: Small components used in electronics, watchmaking, automotive, and medical industries are commonly made from free machining steels.

Precise Mechanical Parts: Free machining steels are preferred for products requiring precise tolerances, such as valves, bolts, nuts, and bearings.

Automotive Industry: They provide durability and precision, especially in engine and transmission parts.

Medical Applications: Used in medical equipment requiring high precision, such as prosthetics and surgical instruments.

What Alloys are Used in the Production of Automatic Steels?

The main distinction of automatic steels is the elements in their chemical composition that enhance machinability. Although this type of steel is mainly derived from carbon steels, it includes various alloys:

Sulfur and Phosphorus: Improve chip formation and increase steel machinability.

Lead: Reduces wear on parts and decreases cutting resistance.

Manganese and Silicon: Enhance durability for longevity.

Chromium: Improves corrosion resistance and gives the steel a shiny appearance.

The carefully determined ratios of these alloys optimize both the mechanical properties and the machinability performance of automatic steel. Manufacturers of automatic steel show great precision in this regard.

What are the Differences Between Automatic Steels and Carbon Steels?

The fundamental difference between carbon steels and automatic steels lies in their chemical composition and machinability features. Below are the details of these differences:

Chemical Composition:

While carbon steels typically contain iron and carbon, automatic steels incorporate the additional alloys mentioned above.

Sulfur and phosphorus are among the most significant distinctions of automatic steels.

Mechanical Properties:

Automatic steel has mechanical properties that facilitate chip formation.

While carbon steels are more durable, automatic steels offer better machinability.

Application Areas:

Carbon steels are used in general structural applications, whereas automatic steels are used in the production of precision and small parts.

In Which Industries are Automatic Steels More Widely Preferred?

Automatic steels are widely used in various industries requiring precision work and a need for rapid production. These industries are as follows:

Automotive Industry: Automatic steel applications include the automotive sector, where parts for engines, transmissions, and brake systems are made from automatic steels.

Electrical and Electronics: Electrical terminals, precision sensors, and connectors are produced with automatic steels.

Watches and Jewelry: Finely processed parts in watch mechanisms and jewelry are made from automatic steels.

Medical: Precision equipment like surgical tools, prostheses, and dental implants are produced with automatic steels.

What are the Characteristics of Automatic Steel?

Automatic steels stand out with their unique mechanical properties:

Easy Chip Formation: Chip formation is quick and orderly.

High Precision: Suitable structure for precise machining.

Wear Resistance: Minimal wear during cutting.

Corrosion Resistance: Resistant to corrosion thanks to special alloys.

Economic Efficiency: Reduces production costs due to rapid machinability.

How to Improve the Mechanical Properties of Automatic Steels?

Automatic steels are materials predominantly used in chip removal manufacturing processes, known for their machinability. Different methods can be employed to enhance their mechanical properties. Firstly, the ratio of carbon and alloy elements in the material should be carefully adjusted. Increasing carbon content improves mechanical properties such as strength and hardness. However, excessively high carbon levels can negatively affect machinability.

Heat treatments play a critical role in enhancing the mechanical properties of automatic steel. Refining steel grains through thermo-mechanical processing can increase strength. Additionally, surface hardening techniques such as carburizing, quenching, and nitriding can make automatic steel more durable.

Alloying elements like manganese, sulfur, phosphorus, and lead significantly impact the mechanical properties of automatic steels. Manganese enhances material strength, while elements like sulfur and phosphorus particularly improve machinability. However, a careful balance of these elements must be maintained; otherwise, the hardness and strength of the steel may be adversely affected.

What Function Does the Lead Element Serve in Automatic Steels?

The lead element in automatic steels is used to enhance machinability, particularly in cutting processes. When lead is homogeneously distributed in the metal matrix, it reduces cutting resistance and extends the life of cutting tools. This property provides a significant advantage for applications requiring precise machining.

Another advantage of lead is that it facilitates easy chip breakage. This enhances the efficiency of the cutting process. However, the use of lead must be approached cautiously due to environmental concerns. Alternative materials are being developed in modern production techniques to replace lead, though its use still remains prevalent.

How is the Weldability and Suitability for Applications Defined?

The weldability of automatic steels is generally limited. Elements present in their composition, such as sulfur and phosphorus, can lead to undesirable structures in the weld region. This situation can reduce the strength of the weld area. When welding is required, these issues can be prevented by using special filler materials and welding techniques.

The limited weldability of automatic steel often results in the preference for machining and surface processing. Therefore, automatic steels are generally used in the production of precision parts, gear manufacturing, and in the production of fasteners like bolts and nuts.

What Processes Are Used to Achieve Different Hardness Levels?

Various heat treatment and surface hardening techniques can be used to achieve different hardness levels in automatic steels. The most common ones include:

Carburizing: Surface hardening with added carbon. This process is ideal for parts that bear heavy loads, such as gears and bearings.

Quenching: High-temperature hardening and tempering processes enhance both strength and hardness of the steel.

Nitriding: Creating a hard layer by adding nitrogen to the surface. This technique significantly increases the wear resistance of the steel.

Induction Hardening: This method provides only surface hardening and can extend the part's life at a lower cost.

These processes allow automatic steel to be customized for different applications. By utilizing these techniques in production, manufacturers can offer products that meet customer requirements.

What Should Companies Selling Automatic Steel Pay Attention To?

Companies selling automatic steel need to pay attention to specific criteria in order to maintain customer satisfaction and competitive advantage in the industry. Firstly, they must be knowledgeable about the characteristics of automatic steel and its machinability details. It is crucial to offer products with the appropriate hardness, durability, and specialized dimensions in line with customer demands.

Another critical factor is establishing effective cooperation with automatic steel producers. Securing quality raw materials can enhance production efficiency and final product quality. Additionally, optimizing logistics and supply chain processes ensures timely deliveries to customers.

When selling, it is essential to provide detailed information on the application areas of automatic steel. These steel's advantages, ranging from the production of precise parts like bolts, nuts, and gears to the automotive and electronics industries, are valuable for potential customers.

Companies must also prioritize environmental responsibility. Taking the necessary precautions regarding the use of environmentally harmful elements like lead is important for both legal compliance and brand reputation.

Providing technical documentation to certify the mechanical properties and machinability of steels will reassure customers. Documents like certificates and test reports demonstrate the professionalism of companies selling automatic steel.

Automatic steels are an indispensable material group in machining processes. Enhancing their mechanical properties, understanding the function of elements like lead, and adapting to various application areas provide a competitive edge in the industry. The application areas of automatic steel encompass a wide range from precise parts like bolts and gears to the automotive and electronics industries.

Automatic steel producers and selling companies that effectively convey the advantages of these steels to customers and offer quality service will find success in the industry. Quality raw materials, effective logistics, and eco-friendly approaches are among the most critical factors in this field.

TR

TR