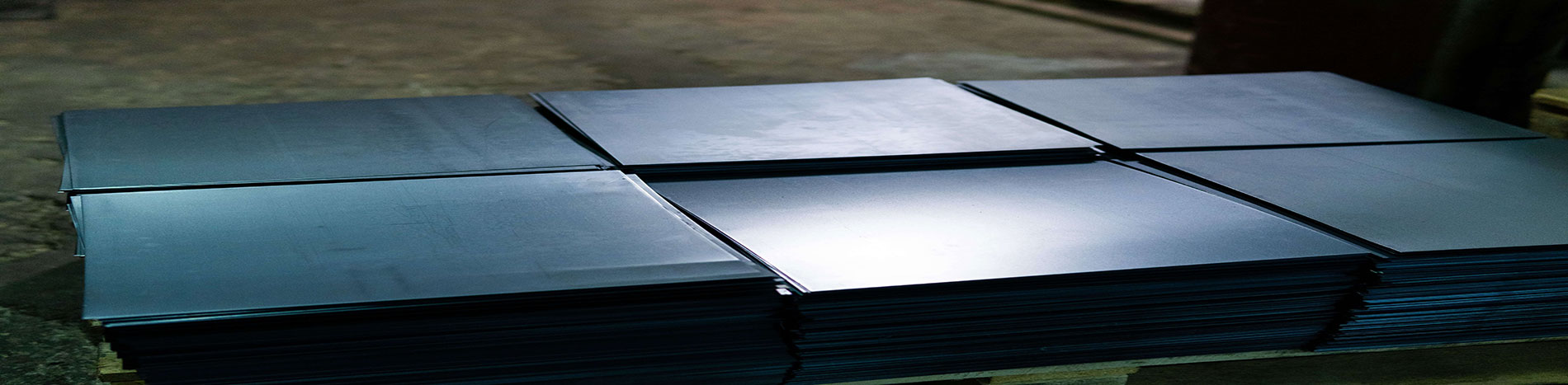

Black sheet prices constantly change due to many factors, from market fluctuations to exchange rates and production cost changes. Supply-demand balance, volatility in raw material supply, and rising energy costs play a significant role in black sheet prices. Additionally, seasonal promotions, discounts on bulk purchases, and supplier competition can sometimes bring these prices to more advantageous levels. At Deha Metal, we always aim to offer competitive figures to our customers; closely monitoring market conditions to determine attractive black sheet prices for both large and small-scale purchases.

Current Black Sheet Prices

Black sheets are indispensable products in the steel industry and have a wide range of uses. This situation leads to high market demand, having a decisive impact on current black sheet prices. Exchange rates, taxes on steel raw material imports, and the global supply-demand balance cause prices to be dynamic. Especially when considering the capacity usage of steel producers, changes in energy costs, and logistics expenses, the prices of black sheets can be frequently updated.

Our company, Deha Metal, closely monitors developments in both local and international markets and provides our customers with the most up-to-date black sheet prices. Setting competitive prices without compromising quality has been among our core priorities since our establishment. With meticulous stock management, we quickly and securely supply the needed products, contributing to maintaining your project's planned cost range.

Black sheet varieties produced in different thicknesses and sizes often carry different price tags. Thicker sheets, using more steel raw material, can increase unit costs. Nonetheless, with special pricing we offer to customers making large or continuous purchases, you can keep your costs under control.

How Are Black Sheet Prices Calculated?

When calculating black sheet prices, the weight and unit price of the sheet are primarily considered. If there are no special processes (cutting, bending, etc.) or additional coatings involved, a simple calculation method may be used. At Deha Metal, we adopt a transparent approach in pricing processes and primarily apply the following formula:

Price = Sheet Weight (kg) × Unit Price (TL/kg)

Sheet Weight: Calculated based on the sheet's width, length, and thickness measurements. For example, a sheet measuring 1,000 mm × 2,000 mm and 3 mm thick has an approximate weight calculated as follows: (1000 × 2000 × 3 × 7.85) / 1,000,000 ≈ 47.1 kg.

Here, 7.85 g/cm³ is the average density of steel.

Unit Price: Represents the steel cost per kilogram as determined by market conditions. Exchange rates and global steel demand play important roles in this figure.

Example Calculation: Sheet Weight: 47.1 kg

Unit Price: 20 TL/kg

Price = 47.1 × 20 = 942 TL

In this example, additional processing or transportation costs are not considered. If cutting, bending, or similar processes are requested, their respective costs are added to the price. At Deha Metal, when creating a detailed price offer according to your needs, we explicitly state all such items.

How Are Black Sheet Prices Determined?

Black sheet prices are determined by the intersection of a series of internal and external factors. At Deha Metal, we closely follow and analyze these elements to make accurate pricing:

- Raw Material Prices:

The price movements of raw materials used in steel production, such as iron ore and scrap steel on global markets, directly affect the cost base of black sheet. - Exchange Rate and Taxes:

For raw materials sourced from abroad, the exchange rate and import taxes are significant parameters. Fluctuations in exchange rates can lead to sudden price changes. - Production Capacity and Energy Costs:

Manufacturers' capacity utilization rates and energy costs are reflected in black sheet prices. Particularly, increases in energy costs can push steel prices to higher levels. - Supply-Demand Balance:

When demand for black sheet rises in the market, prices may move upwards; during periods of decreased demand, more stable or competitive prices may be observed. - Transportation and Logistics Costs:

Logistics costs for shipments to distant areas are an additional factor that can increase prices. Deha Metal tries to keep these costs as low as possible by optimizing logistics processes. - Additional Processes and Stock Management:

Some projects may require additional requests such as cutting, bending, or surface processing on the sheet. These processes can lead to an increase in the final price of the product. Additionally, suppliers' stock management practices and sales strategies can affect price determination.

Deha Metal carefully evaluates all these factors and strives to offer the most accurate prices to our customers. By sharing information about the quantity you demand, the scale of your project, and your technical requirements, we provide tailored solutions and various black sheet price alternatives. Our aim is to establish long-term partnerships and support you in balancing cost and quality.

Following current market data and working with an expert supplier is of great importance in black sheet purchases. At Deha Metal, we aim to facilitate your business with our experience in the industry and constantly updated pricing policy. Upon contacting us, we offer the most competitive quotes for the thickness, size, and quantities suitable for your projects and are there for you whenever you need.