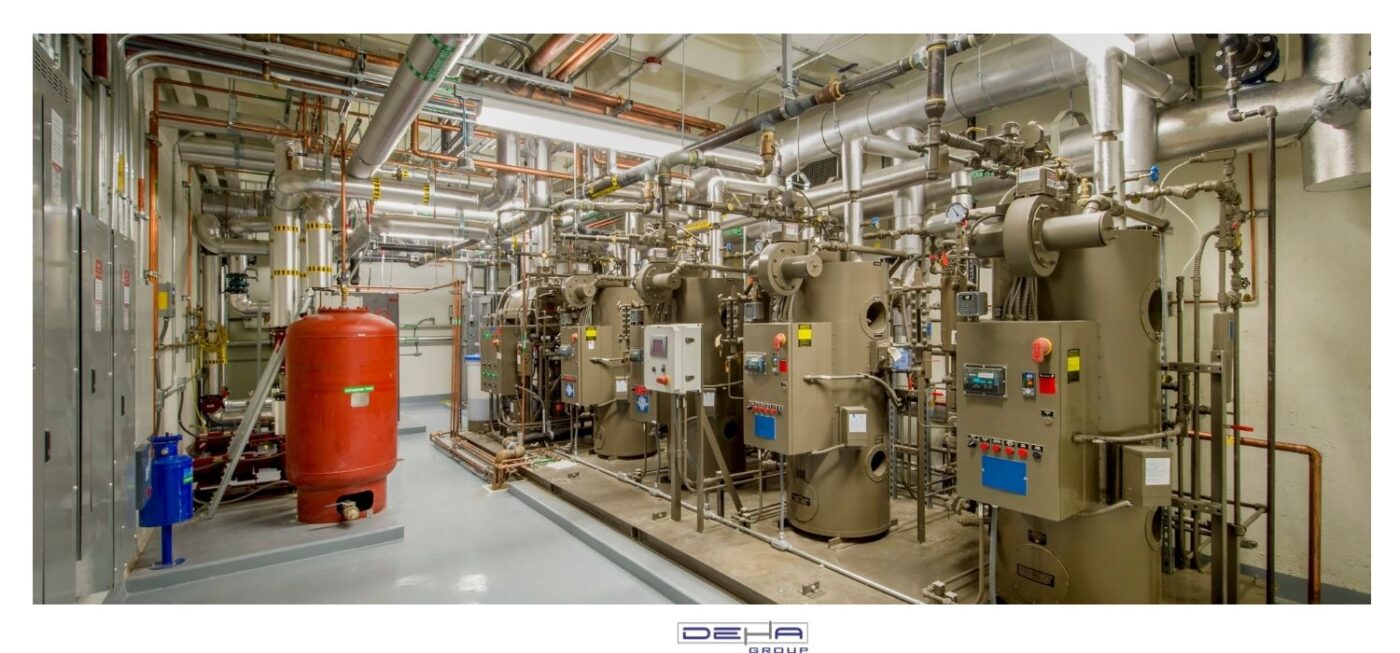

Boiler room heating systems are critical systems used to meet the heating needs of buildings and industrial facilities. These systems hold great importance in terms of energy efficiency and reliability. Boiler room heating systems typically consist of boilers used to produce hot water or steam and the equipment surrounding these boilers. Proper design, installation, and maintenance of these systems are necessary to ensure long-lasting and efficient heating.

Modern boiler room heating systems have highly advanced technologies in terms of energy efficiency. High-efficiency boilers reduce fuel consumption, providing both cost savings and minimizing environmental impact. Additionally, thanks to automatic control systems, energy consumption is optimized, thus preventing unnecessary energy expenditures. This contributes to reducing energy costs for businesses and supports environmental sustainability.

In heating systems of boiler rooms, safety is as important a factor as energy efficiency. These systems should be maintained regularly and operated in accordance with safety standards. Any malfunction that might occur in these systems operating under pressure can pose serious safety risks. Therefore, periodic maintenance and inspections by professional teams are of great importance. Additionally, the use of automatic safety systems and alarm mechanisms ensures that potential risks are detected in advance and precautions are taken.

Boiler room heating systems should be optimized for both energy efficiency and safety. Properly designed and maintained systems offer cost savings in the long run and provide a safe heating solution.

Boilers play a critical role in the production and distribution of heat energy. There are various types of boilers suitable for different applications and needs. These boilers can be categorized based on their working principles, fuel types, and areas of use. Here are the main types of boilers:

Water Tube Boilers

In water tube boilers, water circulates inside the tubes, and the outside of the tubes is surrounded by high-temperature flue gases. This design allows for operation at high pressures and temperatures. They are commonly used in large industrial plants, power stations, and high-capacity steam production. Water tube boilers are known for their high efficiency and large steam production capacities.

Fire Tube Boilers

In fire tube boilers, hot gases pass through the tubes, while water circulates inside the boiler shell. These types of boilers generally operate at lower pressures and temperatures and have smaller capacities. They are widely used in residential buildings, small businesses, and light industrial applications. Fire tube boilers are preferred for their simpler designs and lower costs.

Condensing Boilers

Condensing boilers use the condensation of gas to increase energy efficiency. These boilers achieve high efficiency by recovering the latent heat within exhaust gases. They are widely used in residential and commercial buildings. Condensing boilers stand out as an environmentally friendly option due to their low emission levels and high energy efficiency.

Solid Fuel Boilers

Solid fuel boilers produce heat by using solid fuels such as coal, wood, and pellets. These boilers are typically used in rural areas, farms, and some industrial applications. Solid fuel boilers offer an economical option due to low fuel costs and the ability to use local fuel sources. However, fuel supply and storage can be a disadvantage in terms of ease of use.

Liquid Fuel Boilers

Liquid fuel boilers produce heat by using liquid fuels such as fuel oil and diesel. These boilers are generally used in industrial facilities with high heat demands and large commercial buildings. Liquid fuel boilers offer advantages of high energy density and consistent fuel supply, but fuel costs and environmental impacts should be considered.

Gas Fuel Boilers

Gas fuel boilers produce heat using gas fuels such as natural gas and propane. These boilers are known for their energy efficiency and clean combustion properties. They are widely used in residences, commercial buildings, and industrial facilities. Gas fuel boilers are preferred due to their low emission levels and ease of use, but gas supply and price fluctuations should be taken into account.

Boiler types offer a wide range of options depending on needs and areas of application. Choosing the right type of boiler can significantly impact energy efficiency, cost, and environmental effects.

Boilers Based on Areas of Use

Boilers are produced in various types according to different areas of use and needs. Each boiler type has features specific to certain applications and operational requirements. Here are the main boiler types according to areas of use:

Domestic Boilers

Domestic boilers are used to provide heating and hot water in residential buildings. They are typically designed to be compact, energy-efficient, and operate quietly. These boilers can run on natural gas, liquid fuel, or electricity. Domestic boilers have user-friendly control systems and offer high standards of safety and comfort.

Commercial Boilers

Commercial boilers are used to provide heating and hot water in large commercial facilities such as hotels, schools, hospitals, and office buildings. These boilers are generally high-capacity and designed to meet extensive usage requirements. Energy efficiency and safety measures are of great importance in commercial boilers. Condensing boilers are frequently preferred in this segment.

Industrial Boilers

Industrial boilers are designed for use in factories, power plants, and other large industrial facilities. These boilers have high capacity and durability for the production of large amounts of steam or hot water. Water tube boilers are commonly used in industrial applications because they can operate at high pressures and temperatures. Industrial boilers can typically work with various types of fuel and are optimized to provide high energy efficiency.

Agricultural and Rural Boilers

Agricultural and rural boilers are used on farms, in greenhouse heating systems, and rural settlements. These boilers are typically solid fuel-based, allowing the use of local resources. Their low cost and durability make these types of boilers widely preferred in rural areas. Additionally, they have simple maintenance and operation requirements.

Mobile and Portable Boilers

Mobile and portable boilers are designed for temporary heating needs. They can be used in construction sites, outdoor events, and emergencies. These boilers are typically compact, lightweight, and quick to install. By providing fuel variety, they offer quick solutions for different needs.

Marine and Ship Boilers

Marine and ship boilers are used to meet the heating and energy production needs of ships. They must be durable for marine conditions, compact, and reliable. These boilers generally operate with gas or liquid fuels that provide high efficiency. Ship boilers are designed and operated in compliance with maritime safety standards.

Each area of use has specific requirements and challenges. Therefore, selecting the correct type and capacity of boiler is critical for efficiency, cost, and safety.

Boiler rooms are the heart of buildings' heating systems, and therefore, many considerations must be taken into account during the design, installation, and operation phases. These points are crucial for ensuring a safe and efficient operation. Here are the main considerations for boiler rooms:

Location Selection and Arrangement

The location selection of the boiler room is of great importance for the efficiency and safety of the system. The boiler room should be in an easily accessible and well-ventilated area within the building. Adequate working space should be left around the boilers, and a suitable arrangement should be made for maintenance and repair operations. Additionally, fire exits and emergency routes should be open and accessible.

Ventilation and Chimney Systems

Providing adequate ventilation in the boiler room is a critical factor for safe working conditions. The clean air necessary for the combustion process should be provided, and the waste gases produced as a result of combustion should be effectively evacuated. Chimney systems should be properly designed and periodically inspected. Flue gas analyses should be conducted regularly, and emission limits should be adhered to.

Safety Systems

The installation of safety systems in the boiler room is mandatory. These systems include pressure and temperature sensors, gas leakage detectors, fire alarm systems, and emergency shutdown mechanisms. Moreover, automatic shutdown and alarm systems should be installed on the boilers. Safety systems must be regularly tested and maintained.

Periodic Maintenance and Inspections

Regular maintenance and inspections of boiler room equipment are essential for long-lasting and safe operation. In addition to boilers, pumps, valves, pipes, and other auxiliary equipment should also be periodically checked. These inspections help detect potential malfunctions early and prevent unexpected shutdowns. Additionally, boiler room personnel should have sufficient knowledge and training on this equipment.

Fuel and Energy Management

The type of fuel used in the boiler room and energy management are important in terms of operating costs and environmental impacts. Safety measures should be taken in fuel storage and transportation processes, and fuel consumption should be continuously monitored. To increase energy efficiency, boiler room automation systems can be used, and energy consumption should be optimized.

Compliance with Legal and Standards

The operation of the boiler room must comply with relevant legal regulations and standards. This is necessary for both safety and environmental responsibilities. Local and national regulations provide specific criteria for the design, installation, and operation of boiler rooms. Compliance with these criteria is important for both operational safety and fulfilling legal responsibilities.

Training and Awareness

Regular training and raising awareness of personnel working in the boiler room are required. Personnel should be continuously informed about safety procedures, emergency plans, and the correct operation of the boilers. Training should be supported not only with theoretical knowledge but also with practical applications. Thus, it ensures that personnel can respond correctly and quickly in the face of potential dangers and emergencies.

The considerations for the boiler room are fundamental requirements to ensure a safe, efficient, and sustainable heating system. Adhering to these rules not only increases operational safety but also reduces energy costs, minimizing environmental impacts.

For detailed information on boiler room heating systems and solutions, and for special price and project offers, you can contact Deha Metal. Our professional team is ready to offer solutions that best meet your needs.

TR

TR