Iron and steel are among the most important building materials in human history. Iron is a metal that is abundantly found in nature and is notable for its high durability and malleability. Throughout history, iron has been used in a wide range of applications from weapon making to agricultural tools, and from construction materials to industrial equipment. With the Industrial Revolution, steel production became possible through the alloying of iron with carbon, and steel started to be widely used in industrial and structural applications as a more durable and versatile material.

Steel is an alloy obtained by increasing the carbon content of iron to certain ratios. This increase makes steel a material with different hardness levels and various mechanical properties. Due to its high strength, flexibility, and workability, it has a wide range of applications from the modern construction sector to the automotive industry, and from electronics to medical device manufacturing. Iron and steel, as the cornerstones of industrial development, continue to exist today as indispensable building materials.

Iron, with the chemical symbol Fe and atomic number 26, is a metallic element. It is abundantly found in nature and constitutes a large part of the Earth's crust. Due to its high strength and malleability, iron is widely used as a construction material. Throughout history, it has been used in various forms across many fields, from weapon making to construction materials and from industrial equipment to vehicles. It also plays an important role in biological systems; for example, it functions in transporting oxygen in hemoglobin molecules.

Steel is a material obtained by alloying iron with carbon in certain proportions. The carbon content typically varies between 0.2% and 2.1%, and this mixture gives steel more hardness, durability, and workability compared to iron. Due to its high strength, malleability, and versatile mechanical properties, steel has a wide range of applications. It is used in many fields from the construction industry to the automotive industry, electronics to medical device production. Steel is considered one of the fundamental building blocks of modern industry and plays a vital role in industrial production.

| Feature | Iron | Steel |

| Chemical Composition | Pure iron | Alloy of iron and carbon, may also include other alloys (nickel, chromium, etc.) |

| Carbon Content | Low (usually between 0.04% – 0.3%) | Usually ranges from 0.2% to 2.1% carbon content |

| Durability | Lower, weak in hardness and durability compared to steel | Provides higher hardness and durability |

| Workability | Malleable, but less workable compared to steel | Much more workable, can be shaped in various forms |

| Strength | Low strength, less durable compared to steel | High strength, can have various mechanical properties |

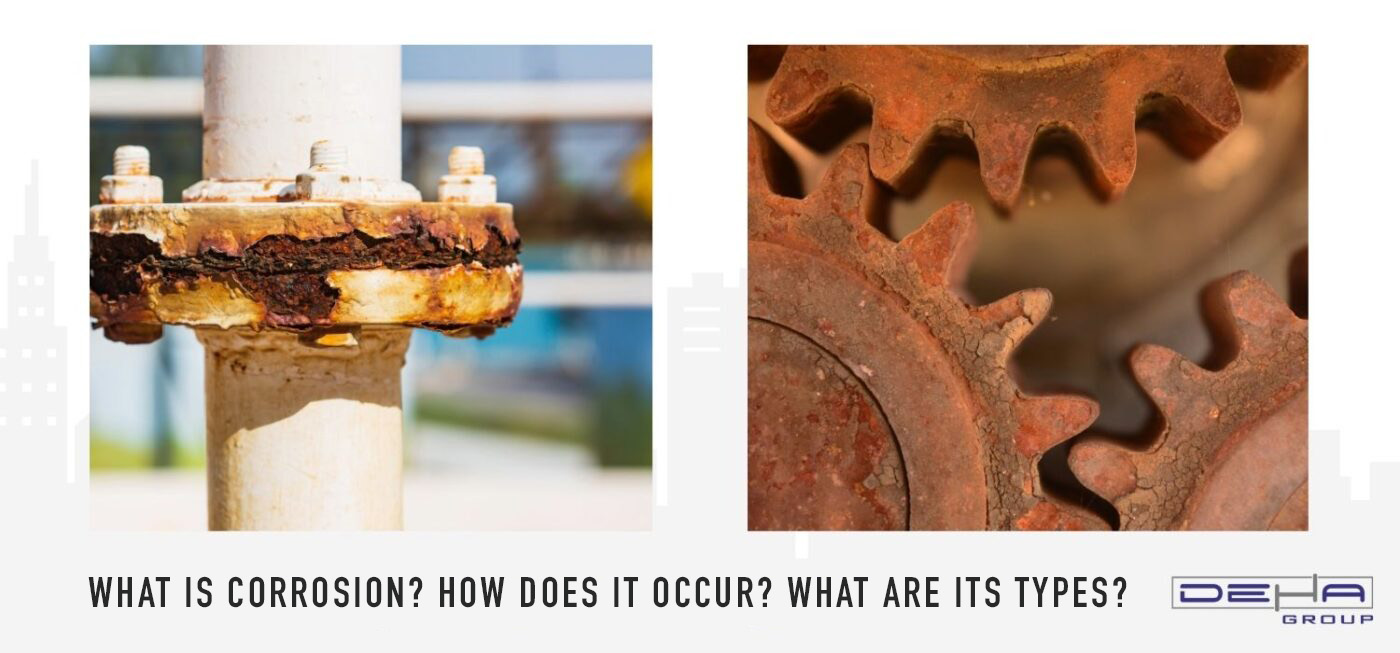

| Rust Resistance | Low rust resistance, prone to corrosion | Generally can rust except for stainless steel types |

| Applications | Used in a wide range of areas such as construction materials, agricultural tools, iron rods | Widely used in areas requiring high strength such as the automotive industry, construction, tools, medical devices |

| Usage Examples | Simple structures like iron rods, iron sheets, wrought iron | Complex structures like car bodies, structural steel, tools, knives |

This table shows in detail the differences in chemical composition, physical properties, durability levels, and application areas of iron and steel.

Iron and steel have many advantages, particularly standing out as ideal options for building materials and industrial applications. Here are the main advantages of iron and steel:

Advantages of Iron

Abundant in Nature: Iron is an element abundantly found in the Earth's crust, making it economically and widely available.

Malleability: Iron is a malleable metal that can be processed and shaped in various forms.

Wide Range of Uses: It has a wide range of applications from construction materials to agricultural tools.

Economic Cost: Compared to other metals, it is generally an economical option.

Advantages of Steel

High Strength: Steel has higher strength than iron, providing more durable and strong structures.

Diversity: It can be diversified with different alloys (carbon, nickel, chromium, etc.), allowing for the production of steel types with various mechanical properties.

Workability: Steel is easy to process and shape, providing flexibility in manufacturing processes.

Various Applications: It has a wide range of applications from the automotive industry to construction, medical devices to kitchen utensils.

Durability: Special types like stainless steel can provide high rust resistance, allowing for the production of long-lasting products.

These advantages explain why iron and steel are preferred in industrial and structural uses and demonstrate their wide range of applications and economic benefits.

TR

TR