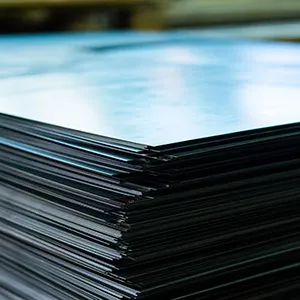

Laser cutting technology has created a significant transformation in the industry and design fields. Laser cutting, which enables fast and precise cutting of materials like metal, wood, acrylic, and plastic, is widely used in many sectors today. However, being informed about laser cutting prices is critically important for individuals and businesses wishing to benefit from this service.

How Are Laser Cutting Prices Calculated?

Laser cutting prices are calculated considering multiple factors. Primarily, the type of material to be cut, its thickness, cutting length, and the complexity of the design are influential in determining the price. Here are the main factors that determine laser cutting prices:

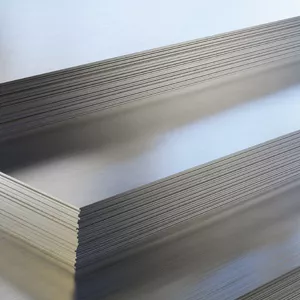

- Material Type:

- Laser cutting prices vary for different materials like metal, wood, acrylic, plastic, or fabric. For example, cutting metals generally requires more energy, which is reflected in the prices.

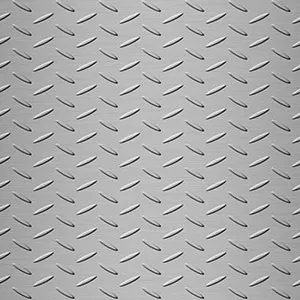

- Material Thickness:

- As the thickness of the material to be cut increases, the time and energy required for the cutting process also increase. This can cause laser cutting prices to rise.

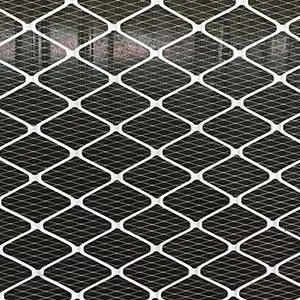

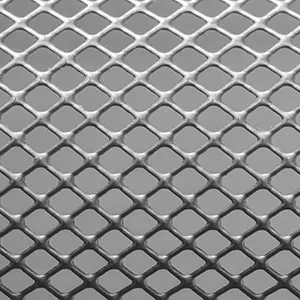

- Design Complexity:

- The level of detail in the design to be cut directly affects the processing time. More complex designs may increase the cost since the laser needs to work longer.

- Cutting Length:

- The total cutting length on the design plays an important role in pricing. Naturally, longer cutting processes lead to higher laser cutting prices.

- Order Quantity:

- In high-volume orders, the unit price generally decreases. Therefore, laser cutting prices can be more economical for bulk orders.

- Additional Services:

- If additional services such as cleaning, edge polishing, or painting are requested after the laser cutting process, these services can also increase the total cost.

What Causes Laser Cutting Prices to Vary?

There are many reasons for the variation in laser cutting prices. These include the equipment used, geographical region, energy costs, and the service provider's level of experience.

- Equipment Quality:

- The quality and capacity of the laser cutting machine used directly affect the prices. High precision and modern equipment generally offer more costly operations.

- Regional Differences:

- The city or region where the laser cutting service is offered is another factor that affects the prices. In major cities, laser cutting prices are usually higher.

- Energy Costs:

- Laser cutting machines are energy-intensive devices. Therefore, increases in electricity costs can be reflected in the prices.

- Experience of the Service Provider:

- Experienced and quality service providers usually demand higher laser cutting prices. However, the quality of service they provide may justify the cost.

- Urgency of the Job:

- Jobs requiring fast delivery are usually charged above standard prices. Therefore, considering delivery times is important when planning.

Current Laser Cutting Prices

As of 2025, laser cutting prices generally vary within the following range:

- Metal Cutting:

- For thickness between 0.5 mm - 2 mm, prices can range from 2 TL to 10 TL per meter.

- For thicker metals, this price can go up to 20 TL.

- Acrylic and Plastic Cutting:

- For materials with 1 mm - 5 mm thickness, prices per meter range from 1 TL to 5 TL.

- Wood Cutting:

- For wood materials between 3 mm - 10 mm, prices can be between 2 TL to 8 TL per meter.

These prices are provided to offer general information and may vary depending on service providers. To obtain more precise information on current laser cutting prices, it is important to request quotes from multiple companies.

Laser cutting prices vary due to many factors. The type of material, design complexity, cutting length, and equipment quality play an important role in determining these prices. By being informed about current laser cutting prices, you can manage your budget more efficiently and realize your projects at the most affordable cost. Remembering to obtain quotes from multiple companies will help you find the best option in terms of both quality and price.

TR

TR