NPU profiles are widely used in the construction and industrial world. These profiles are especially preferred to enhance the durability and stability of steel structures. Offered in various sizes and thicknesses, NPU profiles find a wide range of applications in various sectors. So, what is an NPU profile, in which sectors is it used, and how is it produced?

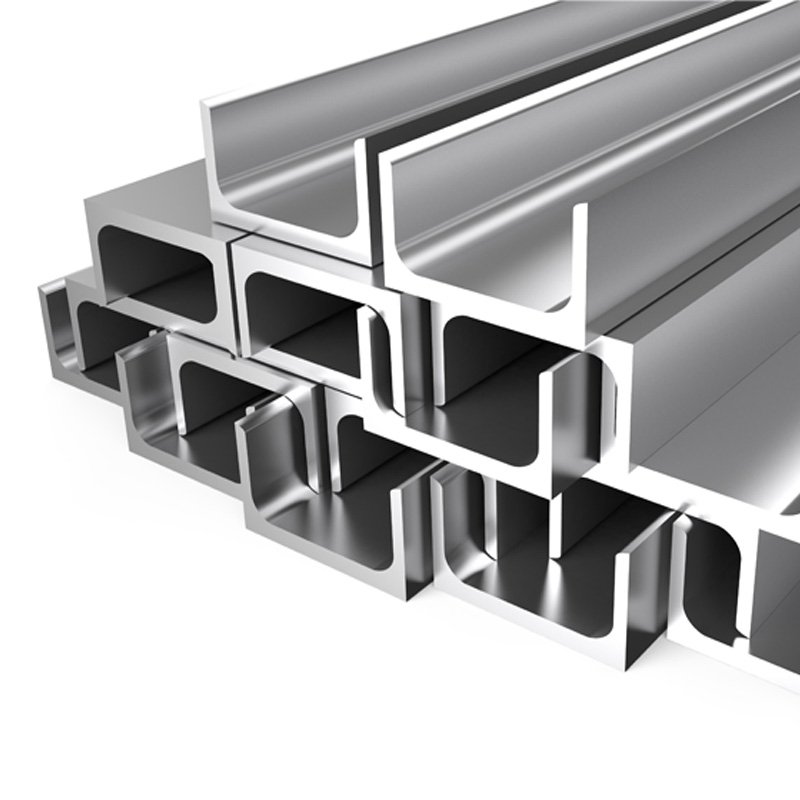

NPU profile is a structural element, typically made from steel material, that has a "U" shaped cross-section. These profiles are preferred as load-bearing structural elements due to their strength and durability. NPU profiles are available in various sizes and thicknesses, which adds versatility to them. They are commonly used in buildings, industrial facilities, bridges, and similar structures.

NPU profiles have a very wide range of applications across various sectors. Here are the main sectors that utilize them:

Construction Sector: NPU profiles are widely used in the load-bearing systems of structures like buildings and bridges. These profiles are ideal for enhancing the durability of structures.

Industrial and Manufacturing Structures: In industrial facilities and factories, NPU profiles are used for machine support systems and steel constructions. They are an indispensable component of systems that bear heavy loads.

Automotive Sector: In the automotive industry, NPU profiles are used in the skeletal structures and support systems of vehicles. These profiles provide both lightness and durability.

Energy Sector: NPU profiles are used in structures like wind turbines and power poles to provide stability.

Maritime and Shipbuilding: NPU profiles are preferred for enhancing the durability and strength in ship and platform constructions.

What Materials Are Used in NPU Profile Production?

The production of NPU profiles generally involves the following materials:

1. Carbon Steel: It is the most commonly preferred material due to its low cost and high strength.

2. Alloy Steel: Provides resistance to rust and greater durability.

3. Galvanized Coating Materials: Used to provide resistance to corrosion.

4. Paint and Coating Materials: Offers protection against external factors and provides an aesthetic appearance.

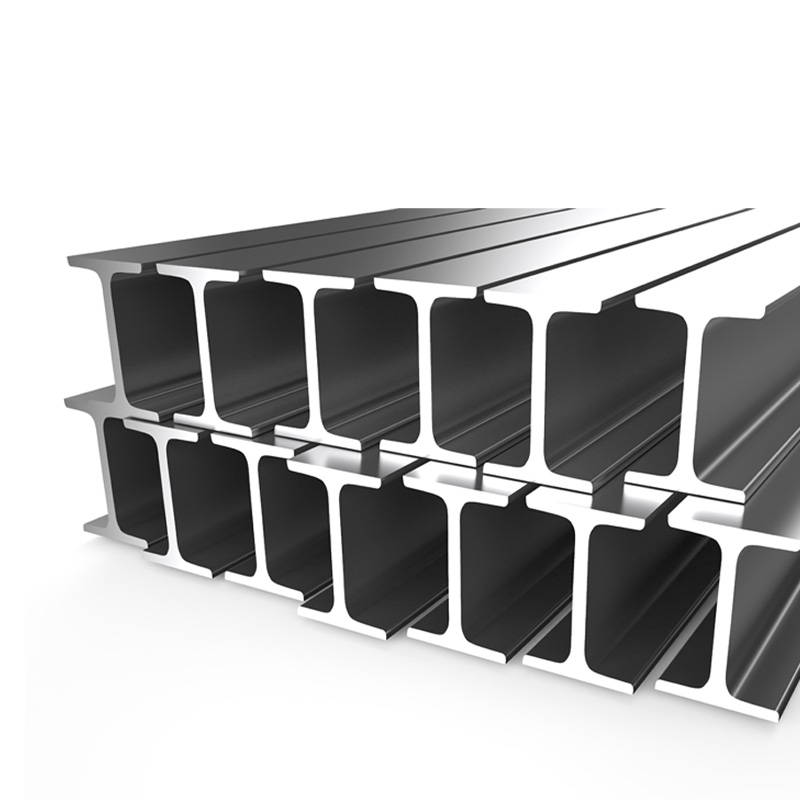

What Are the Differences Between NPU Profile and IPE Beams?

NPU and IPE beams have different application areas and are distinguished by specific characteristics:

Cross-Section Shape: NPU profiles have a "U" shaped cross-section, while IPE beams have an "I" shaped cross-section.

Usage Areas: NPU profiles are generally used as horizontal and vertical structural elements, while IPE beams are more commonly preferred in columns and girders.

Strength and Durability: NPU profiles provide greater tensile strength, whereas IPE beams offer better compressive strength.

Weight: NPU profiles are generally lighter, which facilitates transportation and installation processes.

Main Usage Areas of NPU Profiles in the Construction Sector

NPU profiles are used as a fundamental building material that provides durability, stability, and versatility in the construction sector. They are typically chosen for steel structure systems, column and beam supports, roof constructions, and industrial building projects.

The designs of NPU profiles highlight the strength and durability obtained from steel. Their usage areas in the construction sector can be summarized as follows:

Load-Bearing Systems:

Used as columns and beams in buildings, NPU profiles enhance the stability of structures.

Bridges:

These profiles, offering high load capacity, serve as main support elements in bridges.

Industrial Structures:

They are generally preferred for steel construction in factory and warehouse buildings.

Machinery and Equipment:

Suitable for steel machine frames and equipment chassis.

The robust structure of NPU profiles and their adaptability to a variety of ideas have made them a crucial part of the construction sector.

Technologies Used in the Production of NPU Profiles

The technologies used in the production of NPU profiles ensure these profiles are high-quality and durable. Today, advanced technologies in steel production are employed to reduce costs and adopt environmentally friendly approaches.

- Hot Rolling:

- The most common technique used in shaping NPU profiles. In this method, steel is heated to a malleable temperature and shaped.

- Welding Technology:

- Modern welding techniques are used to assemble profiles and shape them in various dimensions.

- Galvanizing:

- Preferred as a surface coating technology to prevent rusting.

- Quality Control Systems:

- Production errors are minimized with modern sensor and AI-supported systems.

These technologies are developed to enhance both the durability and environmental compatibility of NPU profiles.

What Standards Are Used in NPU Profile Production?

The application of specific standards in NPU profile production ensures the production is of high quality, safe, and compliant with international norms.

EN 10025 Standard:

This standard regulates the mechanical and chemical properties of structural steel profiles.

ISO 9001:

A quality management system standard. It helps factories manage their production processes effectively.

ASTM A36:

This system, part of American standards, aims to test material durability in accordance with given conditions.

The use of these standards allows producers to gain a competitive advantage in both domestic and international markets.

What Are the Coating Methods for NPU Profiles and What Advantages Do They Provide?

The coating of NPU profiles provides resistance to environmental conditions while also making important aesthetic contributions. Coating methods enhance the service life and durability of NPU profiles, offering long-term solutions.

Galvanized Coating:

Makes NPU profiles resistant to corrosion.

Powder Coating:

Creates an aesthetic surface and is environmentally friendly.

Anodic Oxidation:

Improves chemical properties and enhances surface durability.

Thanks to coating methods, NPU profiles become resistant to environmental conditions and their aesthetic features are enhanced.

Turkey’s Global Market Potential in NPU Profile Exports

Turkey is among the leading countries worldwide in the production of NPU profiles. Due to high-quality and cost-effective production processes, the country has become a significant player in the global market.

Strategic Location:

Turkey's proximity to Europe, Asia, and Africa provides a logistical advantage.

Competitive Costs:

NPU profiles are produced more economically in Turkey compared to other countries.

Quality:

Production in compliance with international standards increases demand in export markets.

Market Demand:

Demand from regions such as the European Union, the Middle East, and Africa is increasing every day.

If Turkey continues its investments in this area, it is expected to gain a larger market share globally.

NPU profiles play an important role in the construction sector. These profiles are an indispensable building block for durable structures and international competition.

TR

TR