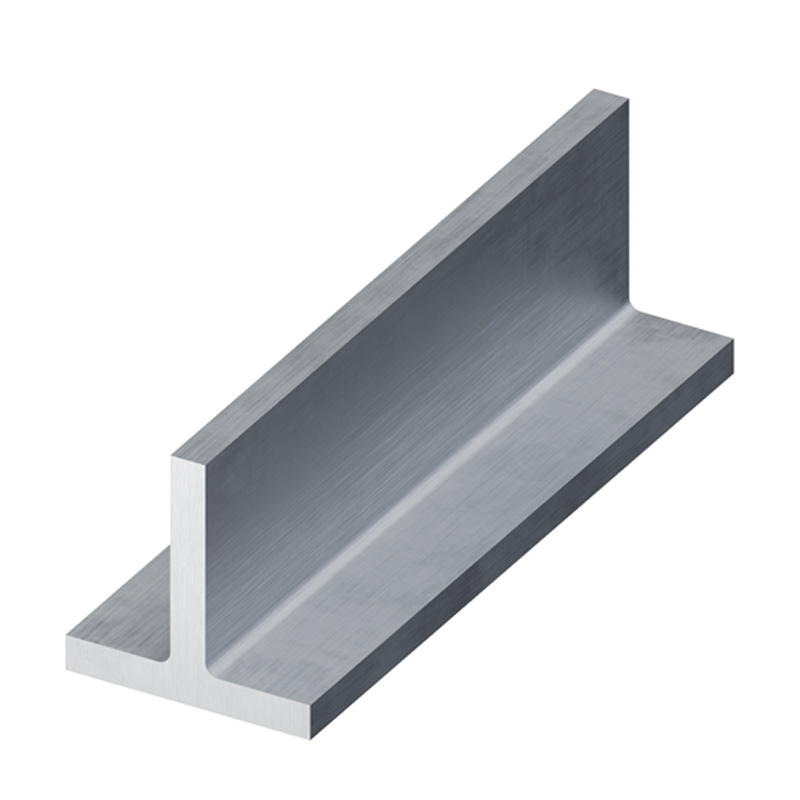

How to Determine the Durability Level of T Profile Irons?

The durability level of T profile iron varies depending on the material used, production techniques, and dimensions. The following factors determine this level:

Material Type

T profile iron is usually made of steel. However, by using different materials such as carbon steel, stainless steel, or aluminum, varying strength characteristics can be achieved according to needs.

Size and Cross-Sectional Area

The cross-sectional area and dimensions of the T iron directly affect the amount of load it can carry. Thicker cross-section T profiles can withstand heavier loads.

Production Standards

T profile irons produced in accordance with international quality standards are more reliable in terms of durability. Standards such as EN and ASTM determine the mechanical properties of the material.

Surface Treatments

T profile iron can be made resistant to corrosion through processes like galvanizing or painting, which extends its lifespan in outdoor applications.

What Materials Are Used in the Production of Profile Irons?

T profile iron production generally involves the following materials:

Carbon Steel

Carbon steel is preferred in projects requiring high durability and flexibility. This material ensures the longevity of structures.

Stainless Steel

Stainless steel T profile iron is preferred for outdoor applications or areas requiring corrosion resistance.

Aluminum

When lightness is a priority, T profiles are produced using aluminum material. This type of material is generally preferred in decorative and portable projects.

Composite Materials

In some special cases, composite materials can be used in T iron production. This can reduce the weight of profiles while increasing durability.

What Tools Are Needed for the Installation of T Profile Irons?

Using the correct equipment during the installation of T profile irons is important. Here are the tools frequently used in this process:

Drills and Fastening Tools

Drills and fastening tools are essential for securing T profile irons to different surfaces.

Welding Machines

Welding machines are used for a more robust installation, allowing T iron to be permanently joined with other metal surfaces.

Cutting Tools

T profile iron is cut to project-appropriate dimensions using a metal cutting saw or laser cutting tools.

Screwdriver and Wrench Sets

Screwdriver and wrench sets are indispensable parts of the installation process for the bolted connections of T iron.

Measuring Tape and Spirit Level

These tools are necessary for making accurate measurements and ensuring that elements are properly aligned during the installation of T profile iron.

What Tools Are Needed for the Installation of T Profile Irons?

The equipment used during T profile iron installation can vary depending on the project requirements and the size of the irons. However, the following tools are generally widely used:

Welding Machine: The most basic tool used to secure T profiles together. A professional welding process is important to achieve a solid and durable structure.

Metal Cutting Saw or Plasma Cutter: Used for cutting T irons to appropriate sizes. These cutting tools provide a smooth and clean surface.

Drill and Drilling Tools: A drill is used to create holes in T profile iron, facilitating the use of connectors during installation.

Bolt and Nut Sets: When bolted connections are preferred instead of welding for joining T profile irons, nut and bolt sets are indispensable.

Level and Measuring Tape: Leveling and measuring tools are essential for the proper installation of T profiles. These tools ensure the structure is aesthetically and functionally correct.

Protective Equipment: Protective gear such as a welding helmet, gloves, and goggles ensure safety during installation.

Using the correct tools increases the durability and longevity of T profile irons. It also contributes to speeding up the work and achieving a higher quality result.

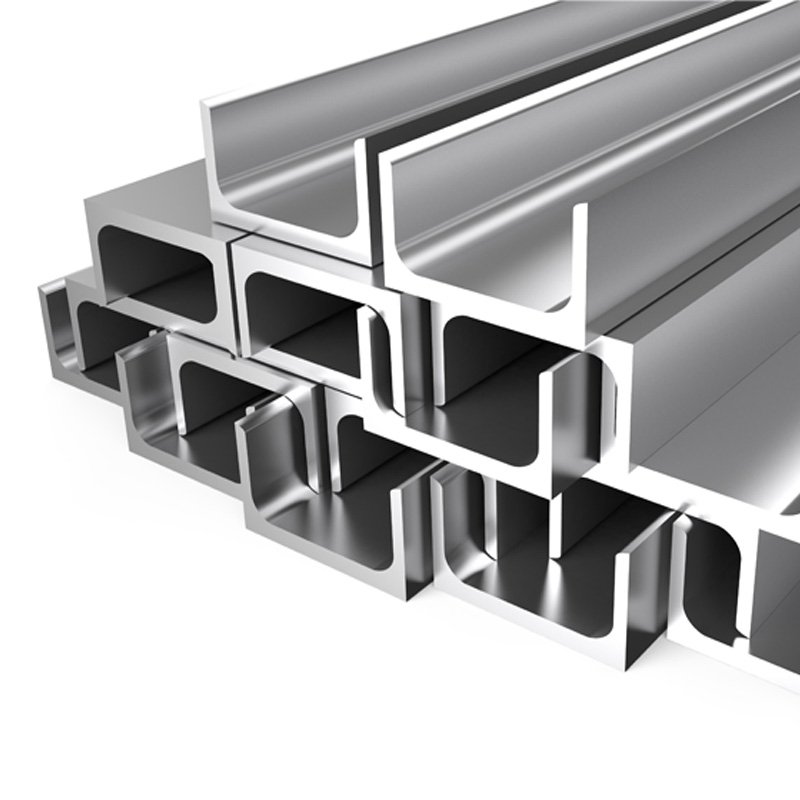

What Differences Exist Among T Profile Iron Types?

T profile iron types are produced to offer solutions suitable for different projects. Some basic differences among these types are:

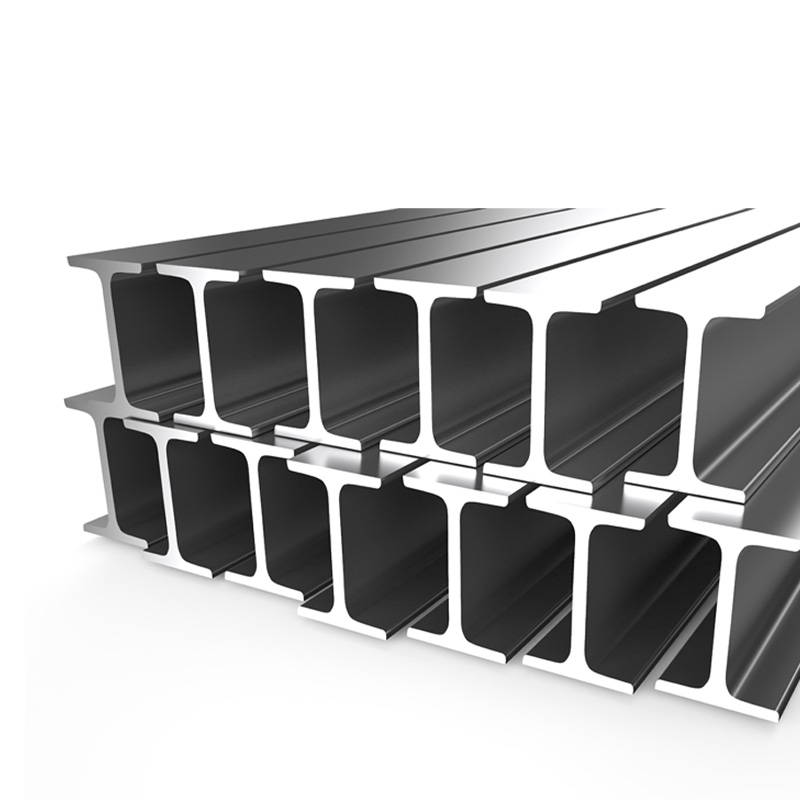

Size and Cross-Section Shapes: The measurements of T profiles, such as width and thickness, vary according to their areas of use. Larger and thicker profiles are preferred in structures carrying heavy loads, while thinner profiles are ideal for light applications.

Material Type: Although T irons are typically made from carbon steel, models with stainless steel or galvanized coating are also available. These materials offer varying levels of durability and corrosion resistance.

Surface Coating: Galvanized or painted T profile irons can be preferred to increase corrosion resistance and provide an aesthetic appearance.

Design According to Use Area: T profiles designed for the construction sector may have different design features compared to those produced for sectors like automotive or furniture.

These differences enable the wide utilization of T profile irons. Making a choice suitable for your project's needs provides advantages in terms of both cost and performance.

How to Increase the Corrosion Resistance of T Profile Irons?

Increasing the corrosion resistance of T profile irons is especially important for structures used outdoors. Here are some ways to boost this resistance:

Galvanized Coating: Applying zinc coating to T irons protects them against moisture and water. This method is one of the most commonly used protection techniques.

Paints and Coating Materials: Applying special anti-corrosion paints to the T profile iron surface minimizes the harmful effects of environmental factors.

Use of Stainless Steel: T profiles made of stainless steel naturally have high corrosion resistance.

Regular Maintenance: Periodically cleaning and maintaining T profiles provides long-term protection against corrosion. This maintenance is especially important in high-humidity environments like seaside areas.

Chemical Treatments: T profile irons can be processed with chemical methods to provide protection against corrosion. Surface treatments like phosphating yield effective results.

These methods extend the life of T profile irons, reducing costs and enhancing the durability of the structure.

What Should Be Considered When Buying T Profile Irons?

There are some critical points to consider when purchasing T profile irons. Here are these considerations:

Material Quality: The material quality of the T profile to be used is extremely important for the safety and durability of the structure. Certified and tested products should be preferred.

Size and Cross-Section Selection: Choosing T iron in dimensions suitable for your project's needs ensures load-bearing capacity and aesthetic compatibility.

Supplier Reliability: Purchasing from a reliable supplier guarantees the products are compliant with standards.

Coating and Processing Details: T profiles to be used outdoors require galvanization or painting for long-lasting use.

Price Comparison: You can get quotes from different suppliers to make a choice that fits your budget. However, you should consider quality, not just focus on price.

Delivery and Storage: Proper delivery and storage of T profile irons facilitate the installation process.

By paying attention to these points, you can choose the most suitable T profile irons for your project, achieving both time and cost savings in the long run.

What Environmental Impacts Does the Use of T Profile Irons Have?

The use of T profile irons can create various positive and negative environmental impacts. Here are these effects:

Recycling Advantage: Since T irons are made of steel, they are recyclable materials. They can be recycled and used to produce new products at the end of their lifecycle.

Long-Lasting Use: Due to their durable structures, T profile irons can be used for extended periods, reducing the consumption of natural resources.

Energy Consumption: High energy consumption can occur during the production process. However, modern production techniques aim to reduce energy consumption.

Environmental Pollution: Corroded T profiles can create visual pollution in the environment. Therefore, protective coatings and regular maintenance are important.

Structural Strength and Durability: The solid structure of T irons enables the construction of safe structures protected from environmental impacts.

Conscious selection and use of T profile irons contribute to minimizing environmental impacts. This is important for a sustainable future and also provides economic advantages.

TR

TR