Trapezoidal sheet price is shaped by production costs, raw material quality, and market conditions, particularly for this product commonly used in construction, roofing, and facade applications. Trapezoidal sheets made from steel materials find their place in various projects due to advantages such as durability and longevity. However, we know that the price factor is also decisive in your planning. At Deha Metal, we adopt a current and customer-focused approach to trapezoidal sheet prices.

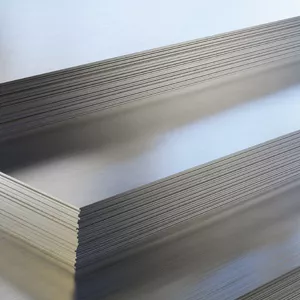

Trapezoidal sheets, having different thickness and size options, can show variability in unit prices. Increased product thickness raises the amount of steel used, affecting costs. On the other hand, it is possible to bring the unit cost to more reasonable levels through bulk purchases in large-scale projects. The carrying capacity of trapezoidal sheets is directly related to their thickness. Therefore, determining the optimal thickness for your projects is a critical step in terms of both durability and cost savings.

An important factor affecting the purchase decision is the coating type and protective features of the sheet. Painted or galvanized trapezoidal sheet varieties increase corrosion resistance and extend the product's lifespan. Therefore, these additional processes can lead to a certain increase in trapezoidal sheet prices. As a company, we strive to offer trapezoidal sheet options that best suit our customers' budget and quality expectations.

Deha Metal provides consultancy in determining the most ideal trapezoidal sheet thickness, dimensions, and coating type according to the nature of your project. In this way, you can create solutions that save on both cost and time in the long term.

Current Trapezoidal Sheet Price

Current trapezoidal sheet price can fluctuate momentarily due to the global and local movements of the steel market. Exchange rates, the supply-demand balance in steel raw materials, and changes in energy costs have a direct impact on trapezoidal sheet prices. We would like to note that prices may increase slightly during periods of high demand but will tend to be more competitive during periods of decreased demand or increased supply.

As Deha Metal, we closely follow developments in the industry and strive to always offer our customers current trapezoidal sheet prices. Transparency is at the forefront of our pricing policy: We clearly express which cost items are included in the price and offer the most reasonable solutions according to your project's needs. This allows you to obtain quality trapezoidal sheets for roofing or facade applications while keeping your projected budget intact.

In some projects, the thickness of the trapezoidal sheet, as well as whether it is coated or painted, may be among the requirements. This affects the product's appearance, durability, and therefore price. Galvanized or painted trapezoidal sheets provide more protection against external factors and can reduce maintenance costs in the long run. While the initial cost of these products may seem higher than standard products, they offer a total cost advantage due to long-term use.

We stock trapezoidal sheets in different thicknesses and sizes for various projects, allowing you to quickly obtain the product in dimensions specific to your needs. To meet your orders on time, we continuously improve our logistics processes and take measures to make stock management efficient.

How is the Trapezoidal Sheet Price Calculated?

Trapezoidal sheet prices are mostly calculated based on the weight of the sheet and the unit price. If additional processes (such as cutting, painting, or special coating) are involved, these are also considered as additional cost items. Below is a basic example formula:

Price = Sheet Weight (kg) × Unit Price (TL/kg) + Additional Process Costs (TL)

- Sheet Weight (kg):

- Thickness of the trapezoidal sheet (mm)

- Width and length (mm)

- Density of the steel (average 7.85 g/cm³)

- For example, to approximately calculate the weight of a trapezoidal sheet with 0.50 mm thickness and 1,000 mm width × 2,000 mm length:

(1,000 × 2,000 × 0.50 × 7.85) / 1,000,000 = 7.85 kg - Unit Price (TL/kg):

- Determined by market conditions

- Exchange rates, steel raw material imports, and energy costs directly reflect on this figure

- Additional Process Costs (TL):

- Cutting, coating, or painting processes

- Transportation or packaging items

Example Calculation:

- Weight: 7.85 kg

- Unit Price: 20 TL/kg

- Additional Cost: 15 TL

Price = (7.85 × 20) + 15 = 157 + 15 = 172 TL

The values in this example are entirely hypothetical and may vary based on your project details. As Deha Metal, our goal is to inform you with the most accurate cost analysis after listening to your project's requirements.

How is the Trapezoidal Sheet Price Determined?

Trapezoidal sheet prices are shaped not only by the cost items mentioned above but also by factors like the competitive structure of the market and the stock status of supplier companies. At Deha Metal, we consider the following factors in the price determination process:

- Raw Material Prices:

Fluctuations in the international market for steel raw materials directly affect trapezoidal sheet prices. Imbalances in supply and demand can lead to rapid changes in prices. - Exchange Rates:

Rises or falls in exchange rates can lead to cost increases related to imported steel raw materials. This plays a significant role in trapezoidal sheet prices. - Energy and Logistics Costs:

Energy costs used in the production stage, shipping, and storage expenses are added to the final product price. This difference becomes more pronounced in shipments to distant locations. - Production Capacity and Demand:

The rapidly growing construction sector or seasonal projects can increase the demand for trapezoidal sheets. While prices may rise when demand is high, they may remain stable or show a downward trend when demand decreases. - Competition and Promotions:

Competition between different supplier companies can lead to advantageous campaigns or discounts for customers. Deha Metal always aims to manage competition in a way that benefits customers.

When all these factors come together, it becomes clear that trapezoidal sheet prices need to be constantly updated and clarified through project-specific analyses. Our goal at Deha Metal is to provide you with transparent and accurate information at all times. When you share the quantity and technical specifications of the trapezoidal sheets you need with us, we can conduct a comprehensive price study and guide you with the most accurate recommendations.

Thus, throughout the process from the beginning to the completion of your project, you achieve a balance of both cost and quality. Remember, beyond trapezoidal sheet prices, fast delivery, adequate stock, and technical consultancy services are among the advantages offered by Deha Metal.

TR

TR