Galvanization is a coating process applied to prevent the rusting of metal surfaces. In this process, a thin layer of zinc is coated onto metals like steel. Zinc slows down or completely stops the rusting process by preventing the metal from coming into contact with oxygen. The galvanization process is a highly effective method for extending the lifespan of steel and iron products. Widely used in industrial applications, galvanization provides significant protection by increasing durability under outdoor conditions.

The galvanizing process is typically done using two main methods: hot-dip galvanizing and electro-galvanizing. In hot-dip galvanizing, the metal is immersed in a bath of molten zinc at high temperatures, covering every surface of the metal with zinc. Electro-galvanizing, on the other hand, is a method where zinc coating is applied with the aid of an electric current. Both methods have their advantages and are chosen according to their areas of use. Especially outdoor metal structures maintain their durability for many years thanks to galvanization.

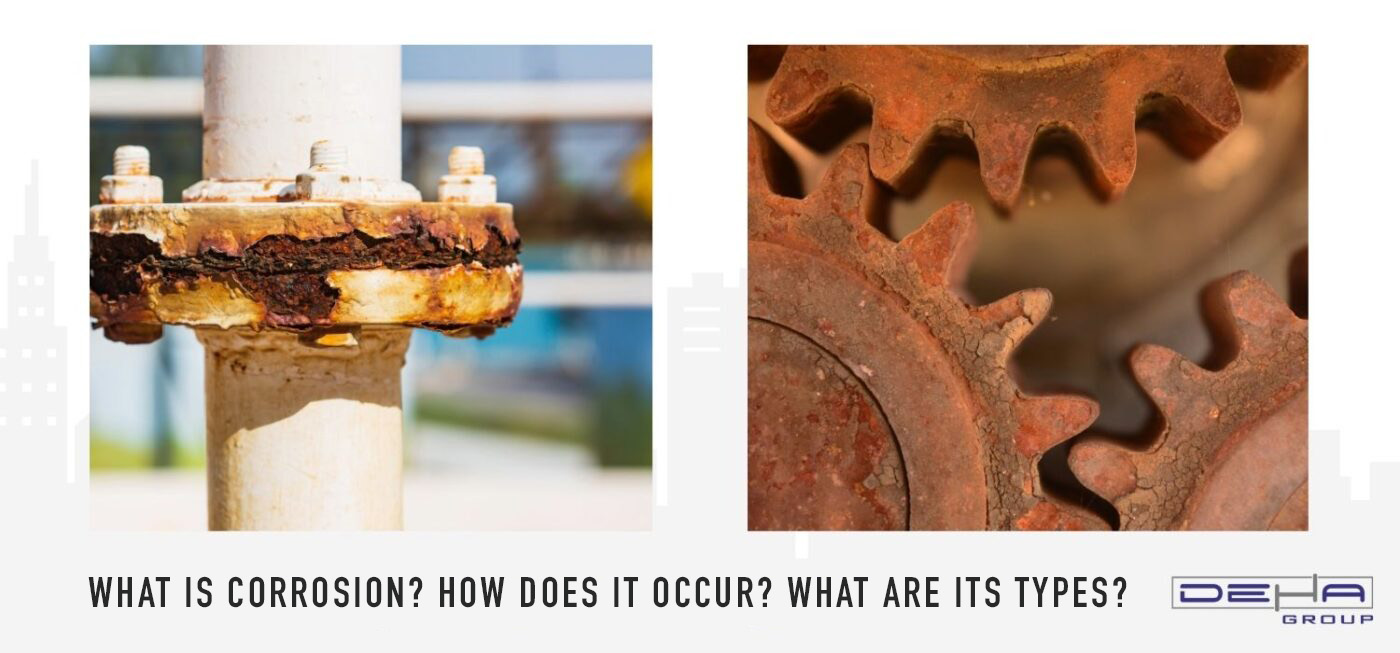

The greatest advantage of galvanization is its ability to protect metal surfaces from corrosion. The zinc layer adheres to the outer surface of the metal, halting the oxidation process and solving the rusting issue that damages the structure of the metal. Galvanized steel products are particularly preferred in fields such as construction, the automotive industry, electrical poles, and pipelines. Thus, galvanization, which reduces the cost of structures, offers long-term protection against environmental conditions.

There are two main methods of galvanization: hot-dip galvanization and electro-galvanization. Hot-dip galvanization involves coating the metal by immersing it in a bath of molten zinc. This method provides comprehensive protection for the metal, forming a homogeneous zinc layer on the surface. The hot-dip method enhances the durability of steel structures used in large-scale projects. In the construction sector, this method is preferred for steel products intended for outdoor use.

Electro-galvanization is a method in which an electric current is used to coat metal with zinc. In this process, zinc ions are transferred to the metal surface by electric current, creating a thin zinc layer. Electro-galvanization provides a thinner and smoother coating, making it preferred for delicate surfaces. For example, in the automotive industry, this method is used for products where an aesthetic and smooth surface is desired.

While both methods serve the purpose of protecting the metal, they offer different advantages depending on the application areas. Hot-dip galvanization forms a thicker protective layer, whereas electro-galvanization provides thin but highly effective protection. The choice of method depends on the intended use of the metal, environmental factors, and aesthetic requirements.

Galvanization is one of the most effective methods used to extend the life of metals. Rust and corrosion are among the most significant issues negatively affecting the durability of metals. The galvanizing process ensures that metal surfaces become more resistant to environmental factors. Especially for metal structures used outdoors, galvanization is an unavoidable solution for longevity. Galvanizing prevents rust by cutting off the metal's contact with oxygen.

Another important benefit is reducing costs. Galvanized steel products require less maintenance. Over time, replacing rusted or corroded metals can result in significant costs. However, thanks to galvanization, metal surfaces provide long-term protection and eliminate the need for recoating. This significantly reduces both material costs and labor costs.

Finally, galvanization also offers environmental benefits. The use of durable and long-lasting products allows for more efficient use of resources. As less metal needs to be renewed or replaced, the negative impacts on the environment decrease. The galvanization process does not prevent the metal from being recyclable, which is an important advantage in terms of environmental sustainability.

Galvanization offers a wide range of applications in many industries. The construction sector is one of the areas where galvanized steel products are most intensively used. Structures such as roof constructions, exterior facades, bridges, and utility poles maintain their durability for years thanks to galvanization. Protecting steel products against corrosion extends the lifespan of structures and reduces maintenance costs in the long term. Therefore, galvanization has become an indispensable solution in large projects requiring durability and safety.

The automotive industry is another significant area of galvanization use. Many automotive parts, such as car bodies, chassis components, and engine parts, are coated with galvanization to protect against rust. This not only ensures that vehicles last longer but also makes them more resistant to external factors. Additionally, galvanized metal surfaces provide a brighter and smoother appearance, offering an important advantage in the automotive sector.

Galvanization is also frequently used in the electrical and energy sector. Utility poles, power transmission lines, substations, and pipelines gain durability against external environmental conditions through galvanizing. The long-term protection of these critical infrastructure elements ensures the reliability of energy and electrical systems. Moreover, the durability provided by galvanization against environmental effects offers sustainable and economic solutions in the energy sector.

TR

TR