Jet grout is an advanced technique used in soil improvement and reinforcement works. This method involves injecting cement slurry into the soil under high pressure. The jet grout process is based on drilling a hole in the ground with a specially designed drilling machine and then injecting cement slurry through this hole at high pressure (usually 200-400 bar). The cement slurry injected at high pressure disrupts the internal structure of the soil, ensuring a thorough mix with the cement and hardening the soil. This way, cylindrical columns filled with cement slurry are formed within the soil. These columns increase the bearing capacity of the soil and provide impermeability.

The jet grout method is a flexible technique that can be effectively used in various types of soil. It yields successful results, especially in soils such as sand, clay, and gravel. This method has a wide range of applications, including foundation strengthening, underground structure construction, water impermeability, and deep excavation support. For example, it is used to strengthen the foundations of buildings and bridges, ensure soil stability in tunnel and metro construction, and increase water tightness in dams and ponds. Jet grout enhances the stability of weak soils, creating safe and durable grounds, and is therefore widely preferred in engineering projects.

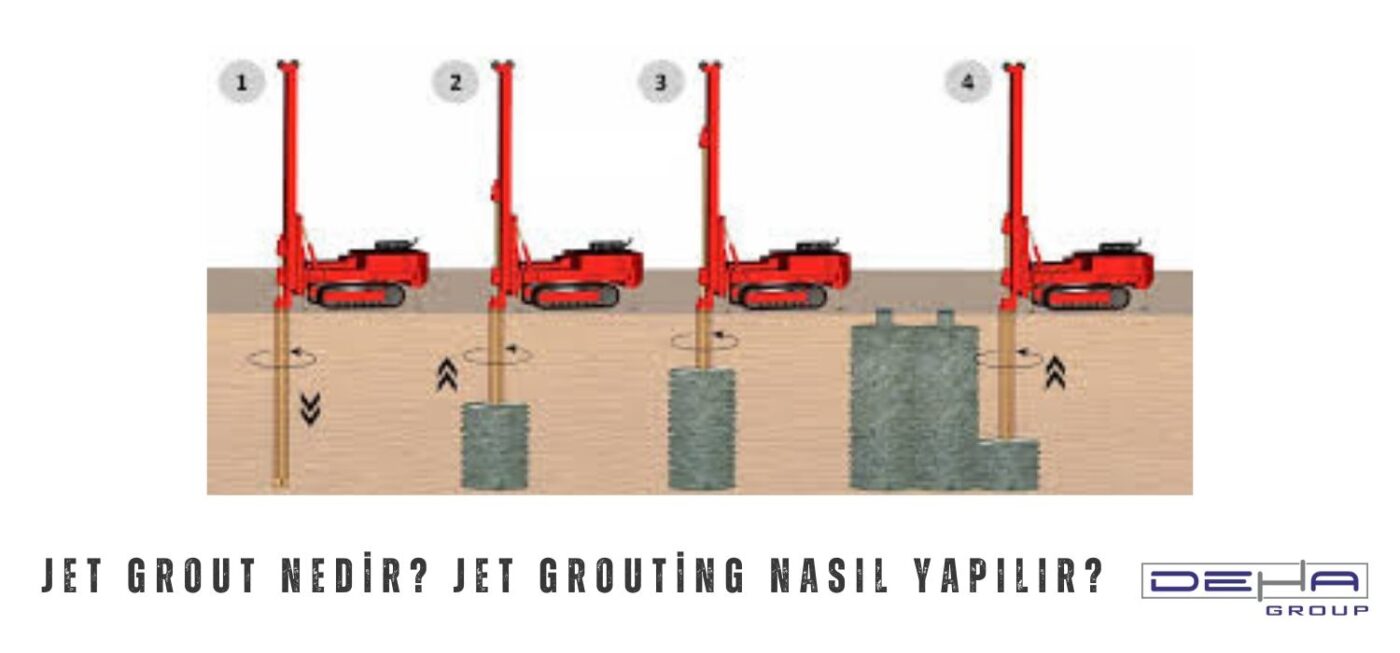

Jet grouting is one of the soil improvement and reinforcement techniques, and the application process consists of the following steps:

Jet Grouting Application Process

Soil Drilling: Before starting the jet grouting process, holes are drilled into the ground using a specially designed drilling machine. These holes are determined based on the soil depth to be treated and the project's requirements. During the drilling process, the diameter and depth of the holes are carefully controlled.

Placement of Injection Pipe: After drilling the hole, the injection pipe (jet grout rod) is placed into the hole. This pipe is equipped with a series of nozzles that allow the grout to be injected into the soil. Once the injection pipe is lowered to the desired soil depth, the injection process begins.

High-Pressure Injection: During the injection process, the grout is injected into the soil through the nozzles of the injection pipe at high pressure (usually 200-400 bar). The high-pressure grout disrupts the natural structure of the soil, ensuring a thorough mix with the grout. This mixture forms cylindrical-shaped columns in the soil.

Pipe Withdrawal and Column Formation: As the injection process is completed, the injection pipe is slowly withdrawn. While the pipe is being withdrawn, grout continues to be injected into the soil. This process ensures the formation of a continuous and homogeneous grout mixture column in the soil. The size and shape of the column are controlled based on factors such as injection pressure, grout flow rate, and pipe withdrawal speed.

Hardening and Inspection: After the grout injection process is completed, a specific period is allowed for the columns formed in the soil to harden. This period varies depending on the type of grout and environmental conditions. Once hardening is complete, the quality of the columns and the effectiveness of the soil improvement process are inspected.

Jet grouting is an effective method widely used in projects such as reinforcing weak soils, foundation reinforcement, providing impermeability, and deep excavation support. This process plays a crucial role in creating safe and durable grounds in geotechnical engineering projects.

Jet grouting is a flexible ground improvement and strengthening method that can be effectively used in a wide variety of soil types. Below are the soil types where jet grouting can be applied and the benefits it provides in each:

Applicable Soil Types

Sandy Soils: Sandy soils are generally low cohesion and highly permeable soils. Jet grouting is used in such soils to increase ground stability and provide impermeability. The high-pressure injected cement grout fills the voids between sand particles, compacting the soil and preventing water passage.

Gravelly Soils: Gravelly soils have large grain sizes and show high permeability. Jet grouting forms columns in gravelly soils, increasing the load-bearing capacity and ensuring water tightness. This method is widely used in gravelly soils, especially in deep excavations and foundation strengthening projects.

Clayey Soils: Clayey soils have high plasticity and low permeability characteristics. Jet grouting is suitable for soil improvement in clayey soils. The cement grout combines with clay particles to enhance the soil's load-bearing capacity and stability.

Silty Soils: Silty soils have grain sizes between sand and clay and demonstrate medium permeability. Jet grouting is used in silty soils for ground strengthening and providing impermeability. The cement grout mixes well with silt particles, forming durable columns in such soils.

Fill Soils: Man-made fill soils are commonly encountered in construction projects. Jet grouting is effective in improving and stabilizing fill soils. This method enhances the load-bearing capacity of the soil depending on the type of fill material and ensures underground water tightness.

Benefits

Increased Load-Bearing Capacity: Jet grouting increases the soil's load-bearing capacity with the injected cement grout, making the foundation systems of structures safer and more durable.

Water Impermeability: Particularly in projects where water tightness is crucial, the jet grouting method helps protect structures by ensuring the soil's impermeability.

Stability and Strengthening: By increasing the stability of weak soils, jet grouting ensures safe execution of construction projects.

Jet grouting is a widely preferred ground improvement method in engineering projects due to its effectiveness across a broad range of soil types.

There are various techniques and types of jet grout methods, each selected according to specific ground conditions and project requirements. Here is detailed information about jet grout techniques and types:

Jet Grout Techniques

Single Fluid Jet Grout: This technique is performed by injecting only cement grout into the ground at high pressure. The single fluid method is simple and economical, commonly used in less complex ground conditions. The cement grout disrupts the ground structure, mixes with the soil, and hardens.

Double Fluid Jet Grout: In this method, high-pressure air (usually 10-20 bar) and cement grout are used together. The cement grout is injected into the ground with high-pressure air, allowing it to spread over a larger area. This technique is suitable for higher performance and creating wider diameter columns.

Triple Fluid Jet Grout: The most advanced jet grout technique, using high-pressure water, air, and cement grout simultaneously. The water washes the soil to enable a more homogeneous mix of cement grout, while the air increases its spread. This technique is preferred in very challenging ground conditions and projects requiring high strength.

Jet Grout Types

Jet Grout Columns: Jet grout columns are used to create cylindrical-shaped columns within the ground. These columns are ideal for increasing the load-bearing capacity of the soil and ensuring impermeability. They can be created using single, double, or triple fluid techniques.

Jet Grout Walls: Jet grout walls are used to create a continuous wall within the ground, especially for ensuring impermeability. This technique is widely used in projects like dams, ponds, and water reservoirs.

Jet Grout Blocks: A technique used to create larger and more homogeneous blocks within the ground. This method is suitable for stabilizing large areas and is often preferred in deep excavations and underground structures construction.

Application Areas and Advantages

Foundation Strengthening: Jet grout techniques are used to strengthen the foundations of buildings and bridges, increasing stability in weak soils.

Water Impermeability: Jet grout walls and blocks are used to ensure water impermeability. They provide water tightness, especially in dam and pond projects.

Deep Excavation Support: Jet grout techniques are used to protect surrounding structures during deep excavations and ensure the stability of the excavation area.

Soil Improvement: Jet grout methods are effective in increasing the load-bearing capacity and stability of different soil types.

Jet grout techniques have a wide range of applications in geotechnical engineering projects, offering effective solutions for soil improvement, stabilization, and ensuring water impermeability.

TR

TR