Galvanized profiles are structural elements where steel materials are subjected to a zinc coating process to increase resistance to corrosion. Frequently used in the construction, automotive, furniture, and energy sectors, these profiles stand out for their long-lasting nature and high strength. Their aesthetic appearance and resistance to environmental conditions make galvanized profiles an ideal choice for both indoor and outdoor projects.

Galvanized profile is steel material enhanced with a zinc coating process to increase its resistance to corrosion. Steel can rust over time due to moisture and weather conditions, and galvanizing is done to prevent this issue. Galvanized profiles are preferred in areas such as construction, furniture, and industry due to their durability and long-lasting nature. These profiles, which can be produced in various dimensions such as thickness, length, and shape, are diversified according to needs. Types of galvanized profiles are generally offered with different designs such as box profile, L profile, and U profile. Due to the extra protection provided by zinc coating, these profiles can be easily used outdoors. Galvanized profile manufacturers produce these profiles according to high-quality standards, offering users a reliable solution.

Galvanized profiles hold an important place in many industries with their wide range of applications. In the construction sector, they are generally preferred for load-bearing systems and roof constructions. Additionally, in the agricultural sector, they are used in greenhouse applications, and in furniture production, they are used for making durable tables and chairs. Galvanized profile types are shaped according to different needs and are also used in decoration projects, the automotive industry, and energy systems. Particularly in outdoor areas, their resistance to rust thanks to the galvanization process makes these profiles stand out. Galvanized profile manufacturers offer specialized solutions for every industry, developing durable and functional products. Therefore, galvanized profiles stand out as a material that meets both aesthetic and functional needs across a wide range.

What Are the Advantages of Galvanized Profiles?

The primary advantage of galvanized profiles is their superior protection against rust. The zinc coating forms a barrier on the profile's surface, preventing corrosion from moisture, water, and other external factors. This extends the product's lifespan and provides cost savings in the long run. Additionally, these profiles offer elegance in decorative projects due to their aesthetic appearance. Galvanized profile types, with their durable structure, are a reliable option for projects requiring high strength. Moreover, these products are environmentally friendly solutions due to their recyclability. Galvanized profile manufacturers provide a wide range of product options to meet every need. With advantages in durability and aesthetics, galvanized profiles are an indispensable part of modern structures.

In Which Industries Are Galvanized Profiles Preferred?

Galvanized profiles are preferred in many industries due to their robust structure and high resistance to corrosion. These versatile profiles, known for their broad range of uses, add value to many sectors due to their durability and longevity.

1. Construction Industry:

In the construction industry, galvanized profiles are extensively used in steel structures, roofing systems, and building construction. These profiles are particularly reliable for outdoor use due to their resistance to rust over many years.

2. Automotive Industry:

Galvanized profiles are frequently used in vehicle chassis, exhaust systems, and transport equipment. They have become indispensable materials in the automotive sector by ensuring vehicles withstand harsh weather conditions.

3. Energy and Electricity:

Galvanized profile types are preferred in solar energy systems, power poles, and cable transport systems. These profiles offer reliability and durability in energy infrastructure.

4. Agriculture and Livestock:

Galvanized profiles are commonly used in greenhouse structures, animal shelters, and fence systems. In this sector, the need for durable and long-lasting construction materials increases the significance of galvanized profiles.

Galvanized profile manufacturers deliver tailored solutions to different industries, making these profiles a top choice across many sectors due to their durability, aesthetic appeal, and longevity.

What Are the Differences Between Galvanized Profiles and Oval Profiles?

The differences between galvanized profiles and oval profiles are as follows:

Material and Coating:

Galvanized Profile: Made from steel and protected against rust by applying a galvanized coating. This is done by adding a thin layer of zinc over the steel profile.

Oval Profile: Unlike traditional flat and angular profiles, this type has an oval shape. It can be galvanized or protected with other coatings, but its oval shape means it may have different functions and uses.

Shape and Design:

Galvanized Profile: Typically found in standard shapes like rectangular, square, or round, widely used in construction, automotive, and industrial applications.

Oval Profile: Used for aesthetic and aerodynamic purposes, often favored in architectural designs and specific mechanical constructions.

Application Areas:

Galvanized Profile: Used for structural purposes, commonly chosen in the construction sector, roofing frames, pipelines, and similar areas.

Oval Profile: Applied where aesthetics and design are important, such as decorative structures, lighting poles, furniture design, and some automotive components.

Durability:

Galvanized Profile: Resistant to rust due to the protective galvanized coating against external elements.

Oval Profile: Durability depends on the material and the type of coating used. These profiles can have their durability enhanced with galvanization or other protective coatings.

Production and Cost:

Galvanized Profile: Generally more common and typically less costly to produce.

Oval Profile: The specific manufacturing process for the oval shape can make it more expensive.

These differences determine where each profile type is preferred. Galvanized profiles are usually chosen for their durability and structural needs, while oval profiles stand out in projects focused on aesthetics and design.

What Techniques Are Used in the Production Process of Galvanized Profiles?

The production of galvanized profiles involves applying various techniques to create materials resistant to rust and long-lasting. Galvanized profile manufacturers adeptly utilize these techniques to offer high-quality profiles suitable for different sectors.

1. Hot-Dip Galvanizing:

In this method, the profile is immersed in a molten zinc bath. The zinc completely covers the profile, providing protection against external factors. The hot-dip method offers high adhesion strength and durability.

2. Electro-Galvanizing:

Involving electric current, this method provides a thin and smooth coating, allowing for a more aesthetic surface. It is preferred for delicate applications.

3. Mechanical Galvanizing:

In this technique, zinc powder and other chemicals are applied to the profile within a mechanical drum, suitable for small parts and special applications.

4. Spray Coating:

Zinc is applied to the profile using a spray method, used for providing thin and controlled coatings in specific areas.

Thanks to these production techniques, galvanized profile types are produced to suit various needs. Choosing the right method directly affects the performance of the profile in its application area. High-quality production processes enhance the durability and reliability of galvanized profiles. Galvanized profile manufacturers offer services with solutions tailored to each sector.

What Are the Types of Galvanized Profiles?

Galvanized profiles are produced in various types for different needs and have a wide range of applications. Galvanized profile types are classified based on shape, size, and application areas. Different designs have been developed by galvanized profile manufacturers to meet the specific requirements of each sector.

1. Square and Rectangular Galvanized Profiles: These profiles are often used in construction projects, steel structures, and roofing systems, known for their durability and strength.

2. Round Galvanized Profiles: Highlighted by their lightweight structure and flexible use, these profiles are commonly used in ventilation systems, decorative applications, and pipe structures.

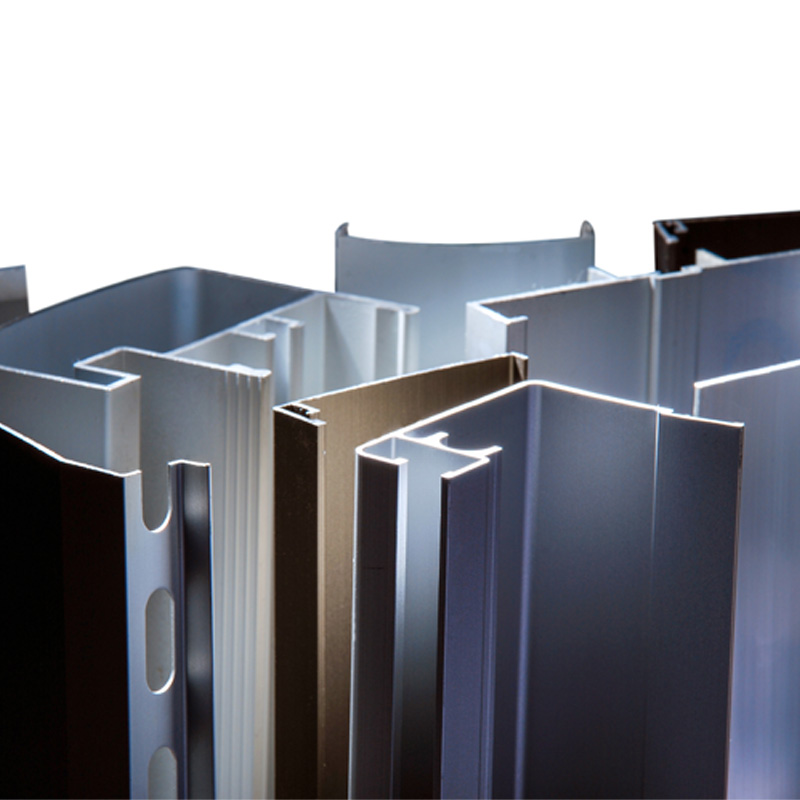

3. Special Design Profiles: Special designs like oval, perforated, or linked profiles are developed for use in the energy sector or agricultural machinery, providing project-specific solutions.

Galvanized profile manufacturers offer a wide range of durable and long-lasting galvanized profile types suitable for every sector. This diversity, catering to various application areas, has made galvanized profiles an indispensable building block of modern industry.

For What Purposes Are Galvanized Profiles Used?

Galvanized profiles are widely used in various sectors due to their durability, long-lasting structure, and resistance to corrosion. Galvanized profile types play a crucial role in industrial and structural projects due to their versatile nature.

1. Construction and Building Sector: Galvanized profiles are extensively used in areas like roof coverings, wall supports, and steel constructions, ensuring the longevity and durability of projects.

2. Automotive Industry: Galvanized profiles are preferred in vehicle skeletons, exhaust systems, and various transport equipment, emphasizing their robustness and resistance to environmental impacts.

3. Agriculture and Livestock: Galvanized profiles hold a significant place in greenhouse structures, fence systems, and agricultural storage areas, offering a perfect solution to the challenging conditions in this sector due to their corrosion resistance.

Galvanized profile manufacturers develop products with different features to meet the changing needs of sectors. With their durability and versatility, galvanized profile types have become an ideal choice across many areas.

What Are the Cost Advantages of Galvanized Profiles?

Galvanized profiles are preferred in many sectors due to the cost advantages they offer in the long term. Galvanized profile manufacturers provide an ideal solution for all projects by combining durability and economic efficiency in the production process.

1. Longevity and Durability: Galvanized profiles are long-lasting due to their corrosion-resistant structure, reducing renewal or repair expenses.

2. Reduced Maintenance Costs: Since galvanized coating prevents rust, it minimizes regular maintenance requirements, which is particularly important for long-term projects.

3. Energy and Material Savings: Galvanized profile manufacturers utilize environmentally friendly production techniques, achieving energy and raw material savings, which reduces costs and environmental impacts.

4. Reasonable Price and Broad Usage Areas: While galvanized profiles may appear slightly more expensive at first glance, their longevity and durability offer cost advantages over time.

The use of galvanized profiles guarantees both cost efficiency and long-term durability in projects. These features are offered by galvanized profile manufacturers tailored to various applications.

What Should Be Considered When Choosing a Galvanized Profile?

Selecting the right galvanized profile is crucial for projects to be long-lasting and durable. Choosing the appropriate galvanized profile ensures cost efficiency and enhances the structure's performance. Certain factors should be carefully evaluated among the different solutions offered by galvanized profile manufacturers to select the most suitable option.

1. Coating Quality: The thickness and uniformity of the coating are critical factors when choosing a galvanized profile. The coating directly affects the profile's resistance to corrosion. The appropriate coating quality for the project ensures long-term protection.

2. Manufacturer Reliability: When selecting from galvanized profile manufacturers, the manufacturer's reliability and experience should be considered. Certified manufacturers with references are more trustworthy in delivering quality products.

3. Project Requirements: When choosing a galvanized profile, the needs of your project should be carefully evaluated. Environmental conditions, load-bearing capacity, and usage area are important factors in determining the right profile.

4. Delivery and Technical Support: When working with galvanized profile manufacturers, the supply process and technical support services should also be considered. Timely delivery and adequate technical support contribute to the smooth progress of projects.

TR

TR