Square profile is a construction material widely used in the construction, automotive, and furniture industries due to its durability and aesthetic appearance. It is typically made from steel, aluminum, or stainless steel. Its robust structure, high load-bearing capacity, and easy workability make it a preferred choice for both industrial and decorative purposes.

Square tubing is a structural element produced from steel materials that have four equal sides and can be either hollow or solid. Generally manufactured from durable metals such as steel, aluminum, and stainless steel, square tubing is widely preferred in many industries due to its high strength.

Frequently used in industrial and structural projects, these profiles are notable for their aesthetic appearance and sturdy construction. As Deha Metal, we offer a wide range of products to produce the highest quality square tubing and provide the best solutions for our customers.

Square profiles find their place in many industries due to their wide range of applications. Thanks to their durability, load-carrying capacity, and aesthetic design, they are commonly used in the following areas:

Construction and Building Sector: Square profiles are preferred for many building components such as steel constructions, roof systems, door and window frames.

Furniture and Decoration: Especially in metal furniture production and interior designs, square profiles offer a modern and durable appearance.

Automotive Industry: Used for vehicle chassis, support systems, and safety equipment.

Machinery and Industrial Production: Machine frames, support systems, and equipment used in production lines are reinforced with square profiles.

Agriculture and Livestock: Stands out for its durability in agricultural sectors such as greenhouse and livestock equipment.

As Deha Metal, we guarantee high quality in your projects by offering the most suitable square profile solutions for our customers' needs.

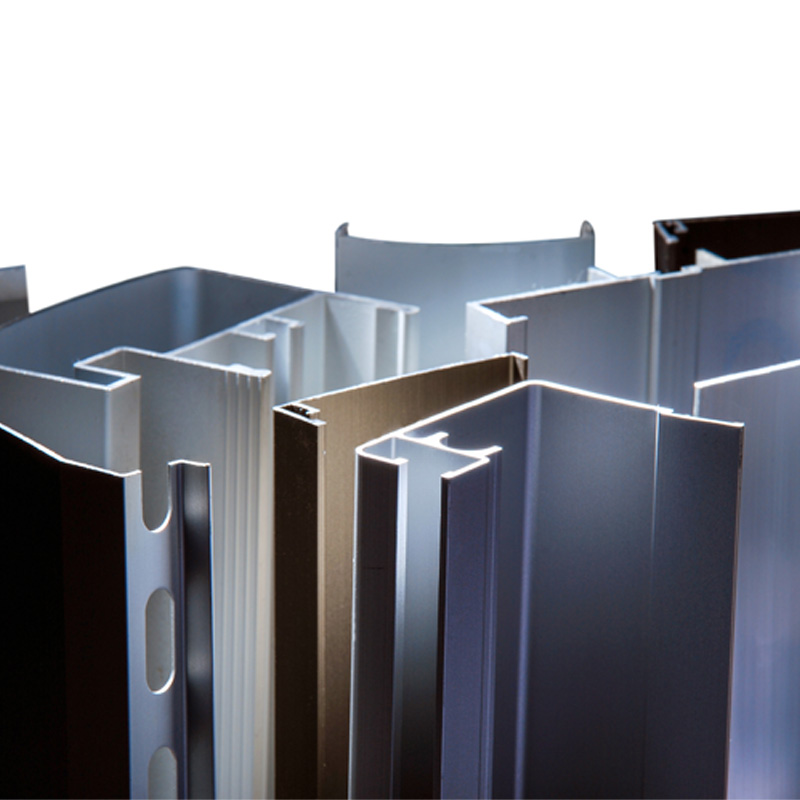

What are the Types of Square Profiles?

Square profiles are produced in different types depending on the manufacturing process and area of use. The types of square profiles we offer at Deha Metal are as follows:

Hot Rolled Square Profiles: These profiles, produced by shaping at high temperatures, stand out for their durability and are preferred in heavy industrial applications.

Cold Rolled Square Profiles: Known for their smoother surface quality and precise dimensional tolerance, they are widely used in construction and decoration projects.

Galvanized Square Profiles: Resistant to rust, these profiles are preferred in outdoor and humid environments.

Stainless Steel Square Profiles: With high chemical and mechanical resistance, these profiles are used in hygienic environments such as the food and pharmaceutical industries.

Aluminum Square Profiles: Thanks to their lightweight structure and corrosion resistance, they are frequently used in the transportation and aviation sectors.

At Deha Metal, our expert team is at your service to help you choose the most suitable square profile for your projects.

What are the Materials Used for Square Profiles?

The materials used in the production of square profiles vary according to the area of use and desired features. The material types of square profiles offered by Deha Metal are as follows:

Carbon Steel: One of the most commonly used material types. It is preferred in the construction and industrial sectors due to its high strength and cost-effectiveness.

Stainless Steel: Used in sectors such as food, chemical, and marine due to its corrosion resistance.

Galvanized Steel: This material, made resistant to rust, is preferred in outdoor and humid environments.

Aluminum: Thanks to its lightweight and durable structure, it is used in the aviation, automotive, and decoration sectors.

At Deha Metal, we offer the most suitable square profile materials for your needs with the highest quality standards.

Advantages of Square Profiles

One of the biggest advantages of square profiles is their sturdiness and durability. Square profiles made from steel, aluminum, and other metals offer high strength for long-lasting use. Additionally, they are made resistant to corrosion through galvanization or painting techniques applied during the manufacturing process.

Besides, square profiles also provide a significant aesthetic advantage. With sharp edges and smooth surfaces, they offer a modern and sleek appearance. Therefore, they are frequently preferred in architectural projects and decorative applications. The fact that square profiles can be welded and easily shaped also facilitates the assembly process, saving on labor and time.

Technical Specifications of Square Profiles

Square profiles can be produced from different materials, which directly affect the features of the product. Square profiles, usually made from steel and aluminum, offer high strength and durability. Square profile manufacturers produce in different dimensions and thicknesses to meet customer demands.

Technical specifications include elements like wall thickness, size, and material quality of the profile. For instance, square profiles used in the construction sector can be thicker and heavier, while those used in decorative applications might be thinner and lighter.

What to Consider When Buying Square Profiles?

There are several important factors to consider when purchasing square profiles. First, the material quality of the product should be evaluated. Square profiles manufactured from high-quality steel or aluminum will be a better choice for long-term use.

Moreover, the production standards and certifications offered by square profile manufacturers should be noted. Manufacturers with ISO and TSE certifications provide quality and reliable products. Additionally, profiles should be chosen in dimensions and thicknesses that meet the requirements of the intended area of use.

How is the Durability of Square Profiles Tested?

The durability of square profiles is measured through various tests during the production stage. Strength tests determine how much load the profile can withstand. Moreover, corrosion tests measure the product's resistance to rust. These tests are particularly crucial for square profiles used in outdoor applications.

Additionally, welding and bending tests are also conducted. Welding tests examine the profile's joining performance, while bending tests assess the product's flexibility and durability. All of these tests are applied in the quality square profile manufacturing process to produce high-standard products.

Square Profile Manufacturers and Manufacturing Process

Square profile manufacturers offer quality products using advanced technologies and modern production techniques. The square profile manufacturing process includes the stages of cutting, shaping, and processing the raw material according to certain standards. Using hot and cold rolled steel sheets in the production process, products with different levels of durability are obtained.

Galvanizing and coating processes ensure the square profiles are protected against corrosion. Additionally, the quality controls carried out during production offer customers long-lasting and reliable products.

What are the Similarities Between Square and Rectangular Profiles?

Square profiles and rectangular profiles are structural elements commonly used in many industries. Both types of profiles hold significant importance in fields such as construction, automotive, furniture, machinery, and industry. Square profile manufacturers and rectangular profile manufacturers produce durable and long-lasting materials by adhering to high-quality standards. There are many similarities between these two types of profiles.

Material Usage and Production Process

Both square profiles and rectangular profiles are typically made of materials such as steel, aluminum, and stainless steel. This enables both profile types to offer high strength and durability. The manufacturing processes of square profiles and rectangular profiles consist of similar stages. During production, hot-rolled or cold-rolled steel sheets are used to obtain profiles in various sizes and thicknesses. Post-production galvanizing, coating, and quality controls enhance the corrosion resistance of the profiles.

Durability and Areas of Use

Square profiles and rectangular profiles have a strong structure that allows for high load-bearing capacity. Both types of profiles are used as load-bearing elements in the construction sector. Preferred in steel construction projects, skeletal systems, roofs, and pillar structures, these profiles are ideal for long-term projects.

Furthermore, square profiles and rectangular profiles are also frequently used in the automotive and machinery sectors. The choice of these profiles in areas requiring high durability, such as chassis and framework structures, enhances project reliability.

Aesthetic and Design Flexibility

Square and rectangular profiles offer a modern and sleek appearance due to their straight-edged structures. The use of these profiles in architectural designs and decorative projects brings together aesthetics and functionality. Furthermore, as these profiles are easy to process and weld, they speed up assembly processes and save labor.

Weldability and Ease of Assembly

Both square profiles and rectangular profiles are highly suitable for welding. During welding, both types of profiles can be easily combined, forming strong connections. This feature that facilitates assembly processes allows for faster and more efficient work in projects.

TR

TR