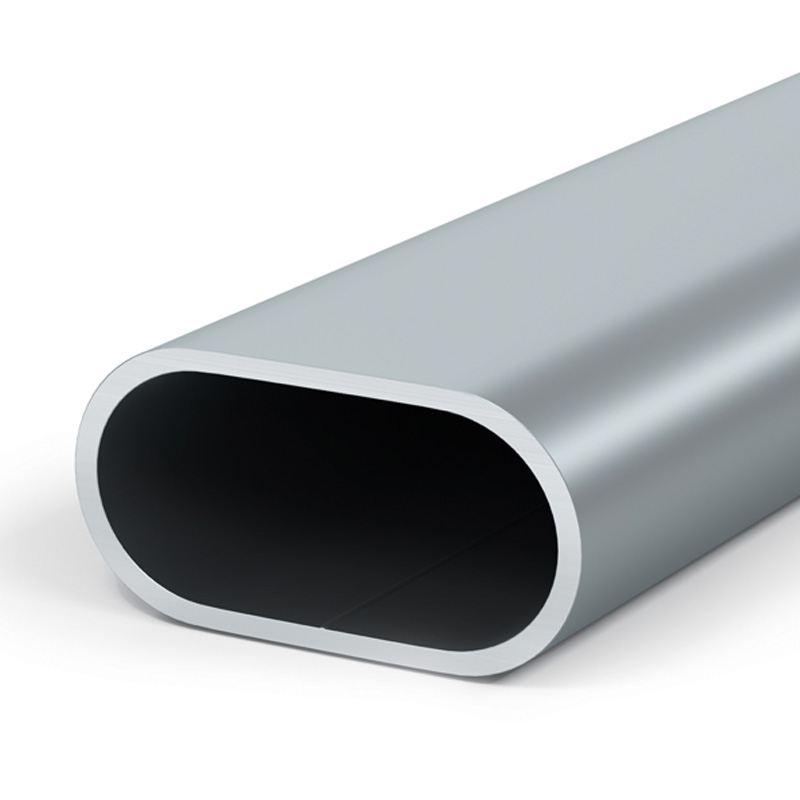

Oval profiles are among the metal materials frequently preferred in the industry. They offer a combination of lightness, durability, and aesthetic appearance. They are especially common in the furniture, construction, automotive, and decoration sectors. With various size and thickness options, they provide flexibility for projects. Additionally, their corrosion-resistant structure ensures long-lasting use.

Oval profile is a type of profile usually made from metal or plastic materials and has an oval-shaped cross-section. Thanks to their rounded lines and aesthetic appearance, oval profiles offer both durability and elegance. These profiles are preferred across a wide range from industrial applications to decorative uses. Produced in various sizes and thicknesses, oval profiles offer solutions suitable for the needs of different sectors.

Oval profiles are typically made from materials such as aluminum, steel, stainless steel, and PVC. These materials ensure that the profiles are long-lasting, durable, and lightweight. The oval shape offers both aerodynamic and ergonomic advantages compared to other cross-sections, making them a preferred option in many fields.

Oval profiles are used in numerous areas due to their aesthetic appearance and functionality. The common application areas of these profiles include:

Furniture and Decoration: Oval profiles are often preferred in furniture designs that seek elegance and modernity. They are used in products such as table legs, chair frames, and shelving systems.

Construction and Architecture: Due to their lightness and durability, oval profiles are used in building facades, railings, and structural supports. They are also included in architectural designs to add an aesthetic touch.

Automotive and Transportation: Oval profiles play a significant role in the automotive industry thanks to their aerodynamic structures. They can be used in products such as vehicle body structures and bicycle frames.

Industry and Machinery: In industrial machinery and equipment, they are used as a material that provides durability and functionality.

Advertising and Signage: Due to their aesthetic appearance, oval profiles are preferred in advertising boards and signage systems.

Oval profiles offer an ideal solution for many sectors with their durability, lightness, and aesthetic structure. With advancements in production processes, it is possible to say that the application areas of oval profiles are steadily expanding.

If you want to obtain more information about the production or application areas of oval profiles, you can contact an expert supplier in the industry.

How is Oval Profile Produced?

The production of oval profiles is typically accomplished with techniques that require high precision. The methods used in the production process may vary depending on the type of material and the intended use.

Raw Material Preparation: The production process of oval profiles starts with the preparation of the selected raw material. Materials such as steel, aluminum, or PVC are prepared to suit the production line.

Shaping: One of the most common methods used in the production of oval profiles is cold drawing or hot rolling. In these methods, the material is shaped into an oval form using special molds.

Welding and Cutting: When necessary, profiles are joined through welding. They are then cut to the desired length.

Coating and Surface Processing: Processes like galvanizing, painting, or anodizing are applied to enhance resistance to corrosion. This stage improves the aesthetic and protective features of the oval profile.

Thanks to technological advancements, the production process of oval profiles is becoming faster and more efficient. Especially processes conducted with CNC machines allow for precise manufacturing of profiles.

Which Materials are Preferred in Oval Profile Production?

Oval profiles are widely preferred across various industries due to their durability, aesthetic structure, and versatility. The materials used in the production of these profiles can vary based on their area of use and needs.

The most commonly used materials include steel, aluminum, stainless steel, and PVC.

Steel Oval Profiles: Steel, known for its high durability and strength, is frequently preferred in construction and the automotive industry. Steel oval profiles can be safely used in structures that carry heavy loads.

Aluminum Oval Profiles: With its lightweight and corrosion-resistant structure, aluminum is a material that is easy to transport and has a long lifespan. It is often used in decorative and interior applications.

Stainless Steel Oval Profiles: Stainless steel oval profiles, which are highly resistant to corrosion, are frequently used in the food, healthcare, and chemical industries.

PVC Oval Profiles: PVC, being a lighter and more economical alternative, is typically used in the decoration and furniture industry. Its low cost makes it a preferred choice for a wide user base.

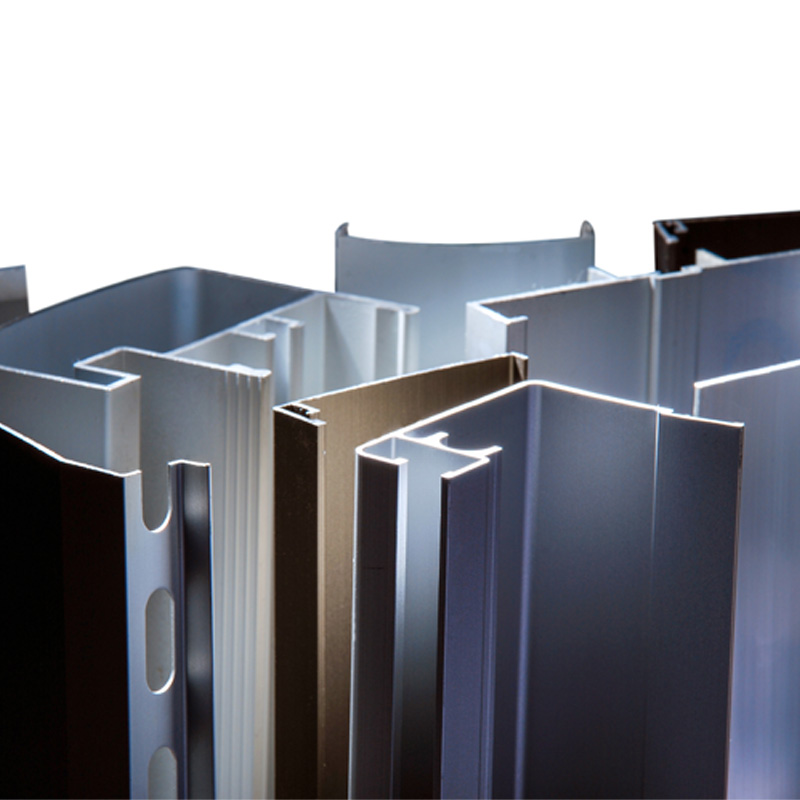

What are the Types of Oval Profiles?

Oval profiles can be categorized into different types according to their designs and areas of use.

Standard Oval Profiles: These profiles, typically characterized by a symmetrical structure, are used in basic carrier elements and decorative applications.

Thin-Wall Oval Profiles: Preferred in structures carrying light loads and in minimalist designs. Its low weight provides practical use.

Thick-Wall Oval Profiles: Used in applications requiring high strength. They are generally used in construction and industrial projects.

Decorative Oval Profiles: These profiles, prominent for their aesthetic appearance, are preferred in interior designs and furniture production.

Custom Production Oval Profiles: These profiles, shaped according to user needs, can be designed and produced specifically for a particular project.

What are the Advantages of Oval Profiles?

Oval profiles offer many advantages both functionally and aesthetically.

Aesthetic Design: Thanks to its oval shape, it provides a modern and stylish appearance. This feature is one of the reasons it is preferred in decoration and architectural projects.

Durability: Thanks to the quality of materials used in production, oval profiles have a long-lasting and durable structure.

Lightweight: Produced with materials like aluminum or thin-wall steel, its lightweight structure allows for easy transportation and installation.

Versatile Use: It can meet different needs in many areas such as construction, automotive, furniture, and interior decoration.

Corrosion Resistance: Especially stainless steel and aluminum oval profiles show high resistance to corrosion, making them suitable for outdoor applications.

Oval profiles have become an indispensable product in many sectors by offering functionality and aesthetic features together. With the ability to be produced in different materials and its variety, it appeals to a wide user base. By choosing the right material, you can find an oval profile that suits your needs.

Where are Oval Profiles More Preferred?

Oval profiles are widely used in various industries due to their aesthetic appearance and aerodynamic features. These products are especially preferred in the following areas:

Furniture Industry: Manufacturers looking to offer modern and elegant designs use oval profiles in chairs, tables, and other decorative furniture. The oval shape provides a graceful appearance while also offering durability.

Automotive Industry: Due to its aerodynamic structure, it is frequently used in the automotive industry. It stands out as an aesthetic option in vehicle frames and decorative parts.

Architecture and Construction: Due to its lightness and durability, oval profiles are preferred in interior and exterior building designs. They are widely used in stair railings, ceiling systems, and decorative partitions.

Advertising and Signage Production: Oval profiles provide a stylish appearance while ensuring that signs are mounted securely.

How is the Durability of Oval Profiles Tested?

Various methods are used to test the durability of oval profiles:

Tensile Test: Conducted to measure the material's durability up to its breaking point. This test helps evaluate the internal strength of the profile.

Bending Test: Determines the profile's capacity for bending when force is applied. This test is essential for measuring the load-bearing capacity of oval profiles.

Corrosion Resistance Test: Profiles used especially in outdoor applications are tested for resistance to rust and environmental effects.

Impact Resistance Test: Determines how an oval profile responds to a sudden force. This test is particularly important for safety equipment.

What to Consider in Oval Profile Manufacturing

During oval profile production, some key points should be considered to enhance quality and durability:

Raw Material Quality: The quality of the steel or aluminum used is critically important for the durability and longevity of oval profiles.

Cutting and Shaping: It is important to shape the profile smoothly and without errors to prevent issues during application.

Welding and Assembly: The welding points should be solid and smooth during the joining processes of the profile.

Surface Coating: Suitable coating methods should be chosen to ensure oval profiles are resistant to rust and corrosion.

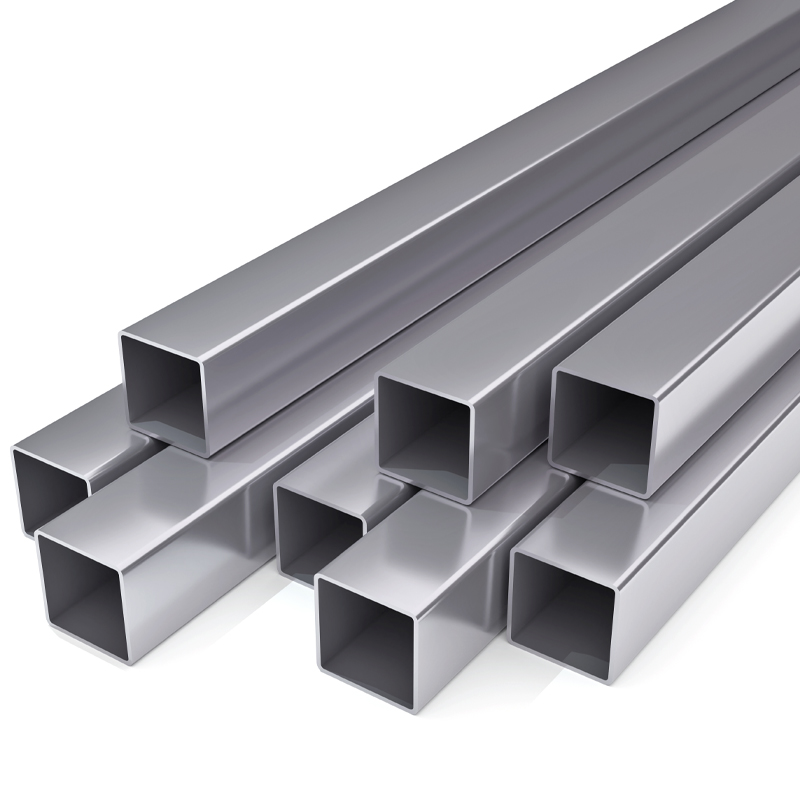

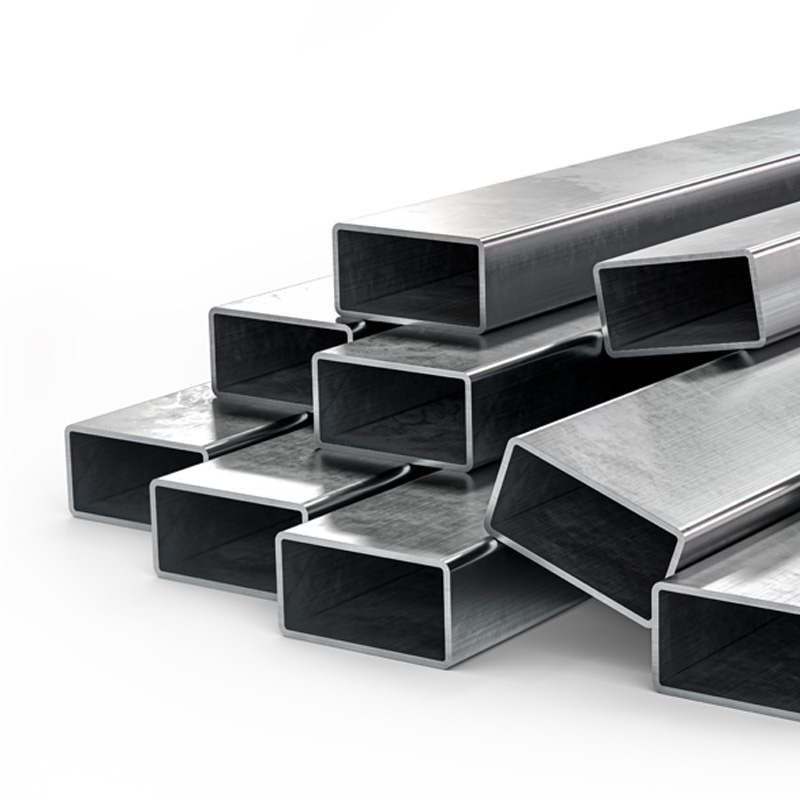

Differences Between Oval Profile and Rectangular Profile

There are significant differences between oval profiles and rectangular profiles both in design and usage:

Aesthetic: Oval profiles offer a more modern and stylish appearance due to their rounded curves. Rectangular profiles offer a sharper and more straightforward design.

Aerodynamic: Oval profiles have a structure that reduces air friction. This feature provides a significant advantage in industries such as automotive and aviation.

Usage Areas: Rectangular profiles are typically preferred in projects requiring a heavy load-bearing capacity, while oval profiles are used in lighter and more decorative applications.

Durability: The round structure of oval profiles provides even load distribution, making them more resistant to breaking and bending.

TR

TR