Rectangular profile is a versatile material frequently used in construction, furniture, automotive, and industrial sectors. Typically made from steel, aluminum, or stainless steel, these profiles offer durability, lightness, and aesthetics. Preferred in framing, support, and decorative applications, rectangular profiles are produced in various sizes, offering a wide range of uses.

Rectangular profile is a structural element in the form of a rectangular cross-section rod or pipe, made from metal or other materials, commonly used in the construction and industrial sectors. Due to its lightweight, durability, and the ability to be produced in different sizes, it has a versatile range of applications. These profiles, which can be made from materials like steel, aluminum, or stainless steel, are an indispensable part of various sectors.

Rectangular profile standards are of great importance in terms of the quality of the products and their suitability for usage areas. Standards cover criteria such as the dimensions, material quality, and surface characteristics of the profiles. Thanks to these standards, profiles are designed to create reliable and long-lasting structures.

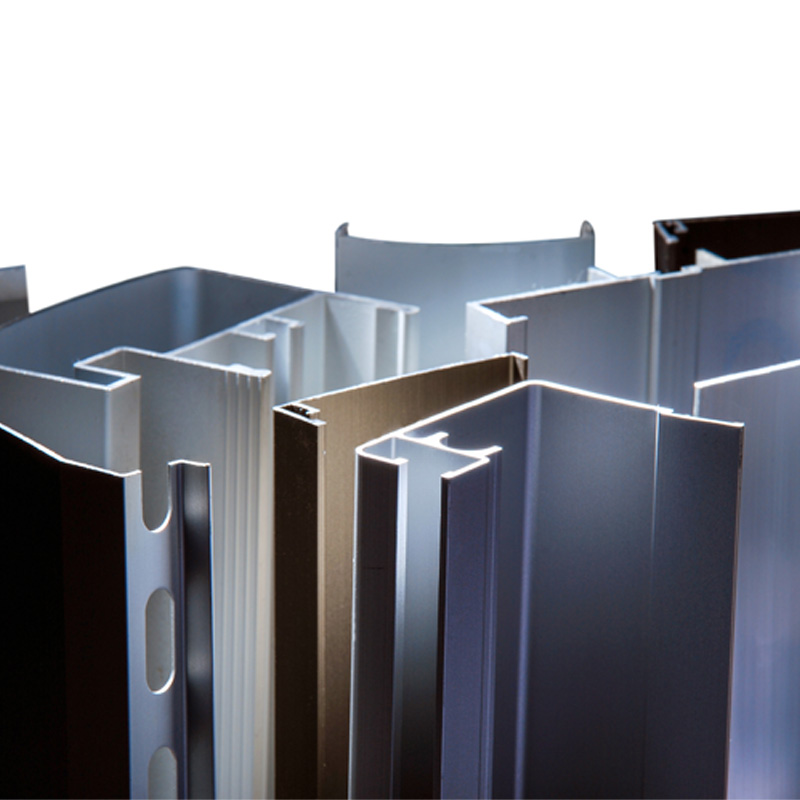

Types of rectangular profiles vary depending on the purpose of use. Thin-section profiles are preferred in lightweight structures, while thick-section and heavy profiles are used in more durable and large-scale projects. These profiles, which gain diversity with perforated, galvanized, or special coating options, can be customized according to the needs of projects.

Producing rectangular profiles in accordance with the correct standards provides advantages in terms of both safety and cost. For long-lasting structures and durable projects, the correct selection of profiles is critically important.

Rectangular profiles have a wide range of uses in various sectors. They are preferred in many areas, from the construction industry to furniture design, from the automotive industry to machinery manufacturing. The durability, aesthetic appeal, and economic advantages they offer are among the main reasons for their preference.

In the construction sector, rectangular profiles are often used in load-bearing systems, roof structures, and building frameworks. Thanks to their lightweight yet durable structure, they are confidently preferred even in large projects. Additionally, the standards of rectangular profiles ensure that these structural elements are suitable in terms of safety and durability.

In the automotive sector, rectangular profiles are used in vehicle bodies, chassis structures, and various connecting elements. The variations of the profile are selected to meet different design and durability requirements during production. Especially among the types of rectangular profiles, thin-sectioned and lightweight structures offer aerodynamic advantages.

In furniture design, profiles used for decorative purposes are ideal for modern and minimalist designs. Due to their lightness and ease of processing, they are frequently chosen in custom-designed furniture. In machinery manufacturing and industrial plants, rectangular profiles stand out as strong and durable connecting elements.

Rectangular profiles offer a reliable solution in every sector thanks to their different varieties and standards. With the right material and standard selection, they contribute to the success of projects.

Structural Features of Rectangular Profiles

The rectangular profile is a material widely used in engineering and construction, noted for its durability and functionality. Rectangular profiles are often chosen for their load-bearing capacity and aesthetic appearance. Produced in various sizes and thicknesses, these profiles offer customized solutions for projects.

The most significant structural feature of the rectangular profile is its rectangular-shaped cross-section. This design makes the profile more robust and durable. Despite its thin-walled structure, it demonstrates high strength and provides ease of use due to its light weight. Rectangular profiles have resistance against bending, buckling, and external factors, which increases their use in both building constructions and industrial applications.

Additionally, rectangular profiles are suitable for various surface treatments. When made from stainless steel or with galvanized coatings, they offer superior resistance to corrosion. Although light, their high load-bearing capacity provides an economical solution, especially for large structures. Rectangular profiles are used in a broad array of areas such as power plants, bridges, shelving systems, and furniture production. Their structural durability and aesthetic compatibility make this material indispensable.

How Are Rectangular Profiles Produced?

The production of rectangular profiles is carried out precisely using modern technology. In the first stage, steel rolls or plates prepared to specific standards are used. These materials are cut and bent into the desired rectangular shape.

The initial step in the production process is the straightening of the steel and cutting it to appropriate sizes. Then, the cut steel plates or strips are shaped in rolling machines. The rolling process allows the material to take on a rectangular form. At this stage, the dimensions of the rectangular profile are precisely controlled and ensured to comply with production standards.

After the shaping process is completed, the profile is welded. The welding process strengthens the joining points of the profile and ensures its sealing. Subsequently, the profiles undergo surface treatments. Galvanized coating or stainless steel surface treatments increase the profiles' resistance to corrosion. The quality control stage is the final step of production. In this stage, rectangular profiles are tested for size, durability, and surface quality.

Thanks to precise production processes, the rectangular profile takes its place in projects as a durable and long-lasting structural element. The advantages provided both during production and in use make this material indispensable for many industries.

What Materials Are Used in the Production of Rectangular Profiles?

Rectangular profiles, preferred frequently in the construction industry due to their durability and versatile application areas, are typically produced using materials such as steel, aluminum, and stainless steel. Steel, known for its high strength and long-lasting structure, is one of the most common choices. Carbon steel, in particular, stands out in projects requiring durability. Aluminum, due to its lightness and corrosion resistance, is preferred more in decorative or low-weight requiring applications. Stainless steel can be used in special projects both for its robustness and aesthetic appearance.

The choice of materials used in the production of rectangular profiles is determined by the needs of the area where the profile will be used. For example, materials with high corrosion resistance are preferred in outdoor applications. Adherence to quality standards in rectangular profile production processes ensures the emergence of long-lasting and durable products. Therefore, the choice of materials directly affects both durability and aesthetic outcomes.

Differences Between Rectangular and Square Profiles

The differences between rectangular and square profiles vary based on their application areas and structural features. Here are the main differences:

Cross-sectional Shape

- Square Profile: Has four sides of equal length.

- Rectangular Profile: Has two long sides and two short sides, with different dimensions.

Durability and Load Distribution

- Square Profiles, with their equal sides, offer balanced load distribution and can be more durable in certain applications.

- Rectangular Profiles, due to their long sides, provide more strength in certain directions, making them advantageous in horizontal load-bearing systems.

Application Areas

- Square Profile: Suitable for construction, steel structure systems, furniture, and decorative applications.

- Rectangular Profile: Preferred in roof systems, load-bearing columns, and structures carrying heavy loads.

Weight and Material Usage

- Square Profiles, due to their symmetric structure, have a more balanced mass distribution in cross-section.

- Rectangular Profiles, potentially having more load-bearing capacity in certain directions, could be ideal for material savings.

Both profile types are widely used in construction, automotive, industrial, and machinery sectors. Choosing the right profile type according to the purpose of use will increase the efficiency of the project.

Advantages of Rectangular Profiles in the Construction Industry

The use of rectangular profiles in the construction industry offers many advantages, such as high strength and design flexibility. Having a wide surface area enhances structural durability, making it easier to carry heavy loads. Rectangular profile types are frequently preferred in columns, beams, and roof systems. These profiles offer economical solutions as they provide high performance despite low material costs.

Rectangular profile varieties can be tailored according to the needs of projects since they are produced in different sizes and thicknesses. Additionally, their weldable structure speeds up assembly processes. Rectangular profiles made from corrosion-resistant materials are ideal for long-lasting projects. Another reason for the preference of these profiles in the construction sector is their compatibility with aesthetic and modern designs, offering a significant solution in terms of both durability and appearance.

What Should Be Considered When Choosing Rectangular Profiles?

There are several important points to consider when selecting a rectangular profile. First, the quality of the material is critical. For a long-lasting and durable structure, the profiles used should be manufactured from high-quality materials such as stainless steel, aluminum, or galvanized coating. The dimensions and wall thickness of rectangular profiles should be chosen according to the purpose of use. Thicker profiles should be preferred, especially in structures carrying heavy loads.

The second essential point is the application area. For instance, rectangular profiles used for decorative purposes in interior designs should be selected from aesthetic and lightweight models. However, products resistant to weather conditions should be chosen for outdoor or industrial uses. Additionally, the load-bearing capacity and ease of assembly of the profile should be considered during the selection process.

The reliability of the supplier is a significant factor. Working with companies that offer certified products and provide quality service presents a more economical and safe solution in the long run.

Which Sectors Are Prominent in the Use of Rectangular Profiles?

Rectangular profiles are prominent in many sectors due to their wide range of applications. The construction industry is one of the areas where these profiles are most intensively used. They are particularly preferred in roofs, staircases, railings, and various load-bearing structural elements. Their durability and easily workable structure make these products indispensable for construction projects.

The furniture sector also frequently uses rectangular profiles. They offer both aesthetic and durable solutions in the production of tables, chairs, shelving systems, and similar furniture. Similarly, the automotive sector utilizes these profiles due to the need for lightweight and durable materials.

Agricultural equipment, industrial machinery, and infrastructure projects also heavily use these profiles. In particular, rectangular profiles provide reliability and long-lasting use in applications like storage racking systems and load-bearing platforms. Thanks to their wide range of applications, they are widely preferred in many sectors.

TR

TR