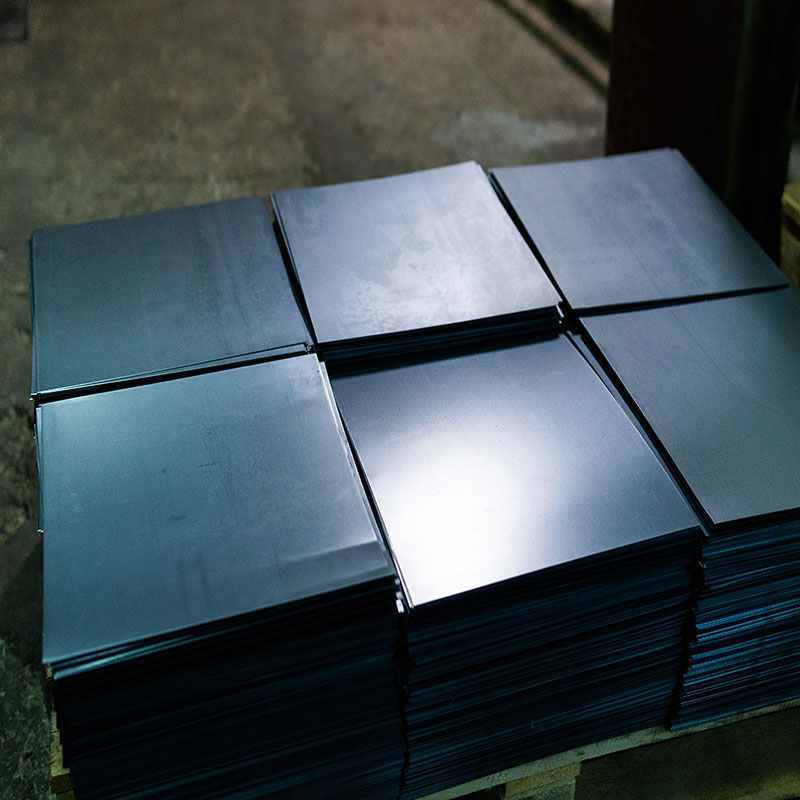

DKP sheet stands for Iron Coated Stainless sheet and is widely used especially in the industrial sector. Preferred for being durable, long-lasting, and economical, DKP sheets play an important role in many areas such as construction, automotive, and white goods production. These sheets, with high surface quality, offer a smooth coating and easy processability.

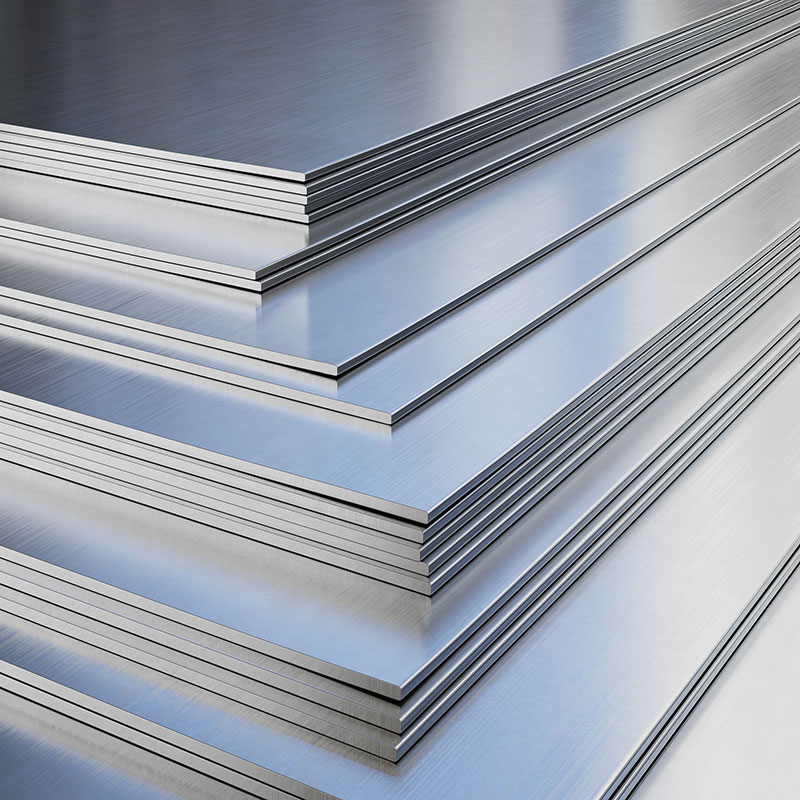

DKP sheet is derived from the abbreviation of "Deep Drawing Press" and is a type of material produced from low-carbon mild steel. It generally has a thin and smooth surface. DKP sheets are very suitable for forming and drawing operations, and they stand out for their durability and workability. DKP sheets, preferred in sectors requiring high quality, are obtained by cold rolling hot-rolled sheets during the production process. This results in a smoother surface and more precise thickness.

DKP sheet materials offer a structure suitable for different projects with their physical and chemical properties. Here are their standout features:

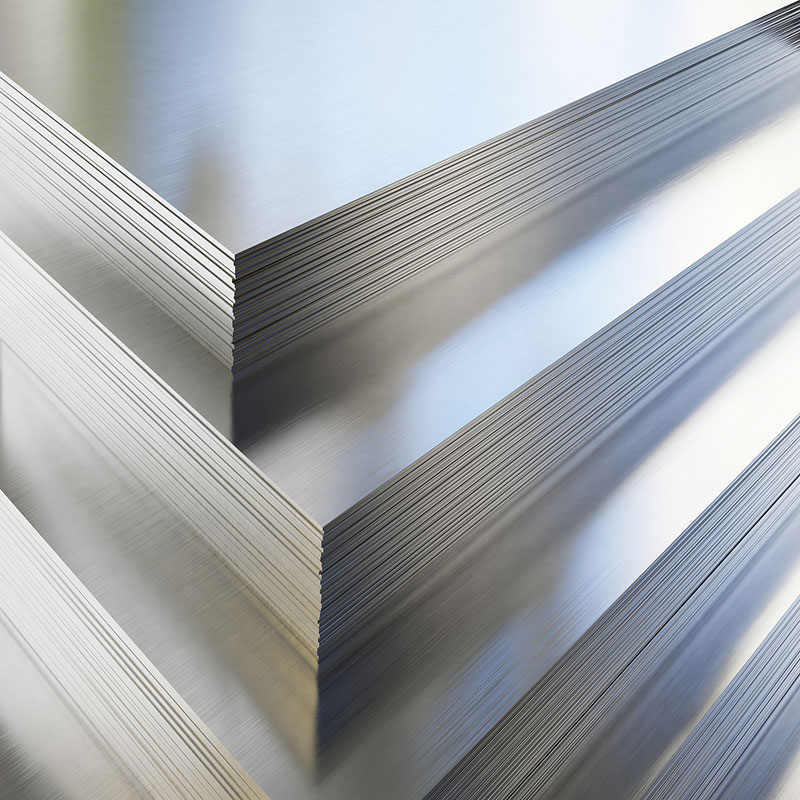

Smooth Surface: Thanks to their cold rolling process, DKP sheets have a highly smooth surface. This feature provides a significant advantage in products where aesthetic requirements are important.

Easy Formability: Due to its thin structure, DKP sheet easily adapts to processes such as bending, cutting, and drawing. It is particularly ideal for deep drawing processes.

High Strength: Despite their light structure, DKP sheets offer long-lasting durability.

Corrosion Resistance: When subjected to processes such as galvanizing or painting, they become highly resistant to corrosion.

Variety: DKP sheet varieties come in a wide range in terms of thickness and size, offering tailored solutions for the needs of different industries.

Where is DKP Sheet Used?

DKP sheet has a wide range of applications and meets various needs in many industries. Below you can explore the areas where this material is most commonly used:

Automotive Industry: DKP sheets are widely used in the automotive sector for the production of vehicle bodies, bodywork parts, and engine covers. The main reason for the automotive industry's preference for this material is its easy formability due to its thin structure.

White Goods Production: DKP sheets are frequently used in white goods such as washing machines, refrigerators, and ovens. In these products, a smooth surface and durability are of great importance.

Furniture Production: Different varieties of DKP sheet are used in metal furniture designs, especially in products like cabinets, tables, and chairs. Its aesthetic appearance and strength increase its use in the furniture sector.

Construction Sector: DKP sheets are utilized in the production of structural elements and decorative products in construction projects. Its lightness and high durability provide a great advantage in this sector.

Electronic and Mechanical Parts: DKP sheets are used in electrical panels, small machine parts, and various electronic device cases.

What are the Differences Between DKP Sheet and Galvanized Sheet?

DKP (deep drawing sheet) and galvanized sheet are types of sheets used for different purposes and have different properties. Here are the main differences between them:

1. Production and Surface Treatment

DKP Sheet

Specially produced for deep drawing processes.

Cold-rolled sheets with a smooth surface.

Generally, the surface is uncoated, so it does not provide protection against corrosion.

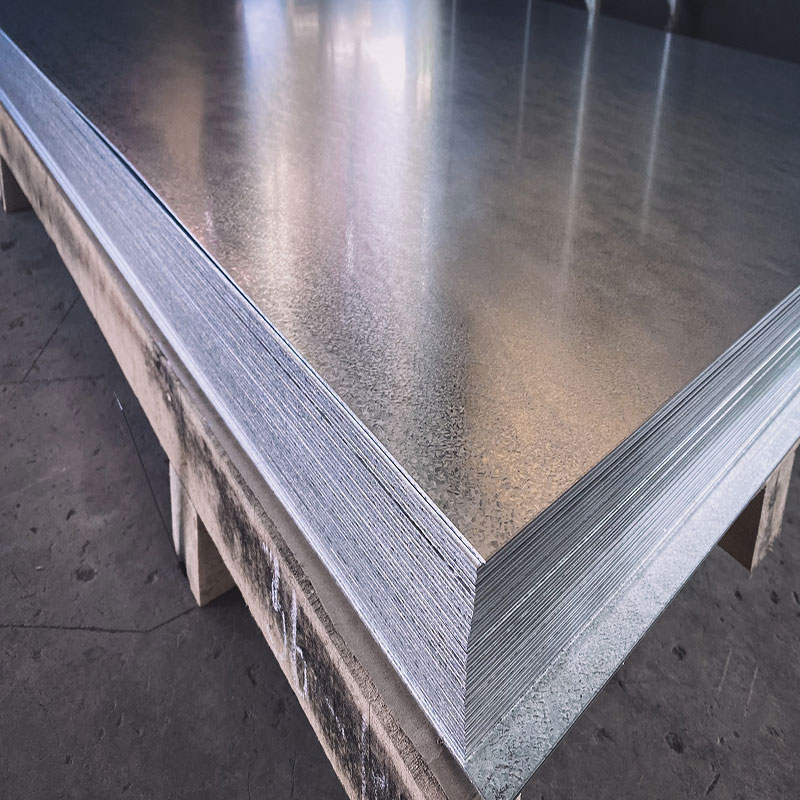

Galvanized Sheet

Coated with zinc.

Zinc coating provides excellent protection against corrosion.

Preferred for outdoor applications due to its rust resistance.

2. Areas of Use

DKP Sheet

Used in areas requiring deep drawing processes (e.g., automotive industry).

Also preferred for furniture, white goods, and various decorative purposes.

Galvanized Sheet

Used in roofing, exterior applications, ventilation systems, and other outdoor areas.

Common in electrical panels and products requiring corrosion resistance.

3. Corrosion Resistance

DKP Sheet: Not resistant to corrosion and requires protection against rust in outdoor environments.

Galvanized Sheet: Resistant to corrosion thanks to the zinc coating.

4. Workability

DKP Sheet: Easily formable due to its flexible structure and suitable for deep drawing processes.

Galvanized Sheet: The zinc coating may peel off or get damaged during processing, requiring care during handling.

5. Cost

DKP Sheet: Generally more economical than galvanized sheets. However, additional processes for corrosion protection may increase costs.

Galvanized Sheet: Usually more expensive due to zinc coating but can reduce long-term maintenance costs due to rust resistance.

The Production Process of DKP Sheets

The production of DKP sheets requires meticulous and careful work. The production process begins with the selection of high-quality steel raw materials. These raw materials are subjected to special rolling processes to produce sheets of the desired thickness and smoothness. DKP sheet manufacturers typically carry out this process with high-tech equipment that is crucial for optimizing the surface quality and strength of the sheets.

Another important stage in the production process is the annealing process. During annealing, the sheets are heated to a specific temperature and then slowly cooled. This process improves the mechanical properties of the sheets and reduces potential surface stresses. The smooth surface of DKP sheets is also obtained during these processes. Moreover, special coating and cleaning techniques used in the production process make the sheets suitable for painting and other processes.

DKP sheet varieties diversify due to differences in this production process. For instance, some sheets are produced thinner, while others are made thicker and more durable. This variety increases the applicability of DKP sheets in different sectors.

The Importance of DKP Sheets in Construction and Building Materials

DKP sheets hold critical importance in construction and building materials. Due to their high strength and smooth surface structures, they offer significant advantages both aesthetically and functionally. DKP sheet varieties are widely preferred especially in applications such as roofing, wall panels, and decorative elements.

These sheets are an ideal choice for designers seeking lightness and durability in construction projects. Their light structures reduce building loads, providing a cost advantage. Additionally, the suitability of DKP sheets for painting and coating processes enhances the aesthetic appearance of structures. DKP sheet manufacturers provide sheets in various sizes and properties tailored to the construction sector to meet different needs.

Another advantage of DKP sheets is their corrosion resistance. Thanks to special coatings, these sheets are resistant to moisture and weather conditions, offering a significant advantage especially in outdoor applications. Furthermore, DKP sheets are recyclable materials, making them an environmentally friendly choice.

DKP sheets offer sustainable solutions both economically and environmentally in the construction and building materials sector. Innovative approaches by DKP sheet manufacturers continually expand the application areas of these products, making them an indispensable part of modern construction projects.

Challenges in the Production and Use of DKP Sheets

DKP sheet is a durable and versatile material widely used in the industry. However, the production and use process of DKP sheet may involve certain challenges. During production, the quality of the raw material and the selection of appropriate processing techniques are of great importance. DKP sheet manufacturers must establish a careful quality control system to prevent microscopic cracks and deformations that may occur on the steel surface. During use, the resistance level of DKP sheet to environmental factors (humidity, temperature changes) must be carefully evaluated.

Another common challenge is the appropriate material selection among DKP sheet varieties. Each DKP sheet variety targets a different area of use, and an incorrect material choice can increase project costs or lead to functional loss. Therefore, both companies selling DKP sheets and users must understand the technical specifications of the product and make choices suitable for the application area.

Surface Defects in DKP Sheets and Solution Suggestions

Surface defects in DKP sheets can result from manufacturing errors or negligence during transportation and storage. Some common surface defects include:

Wrinkles: This issue can arise from incorrect tension settings during DKP sheet production.

Rust: DKP sheets can be susceptible to rust in unsuitable storage conditions.

Cracks and Holes: These issues can occur on the steel surface due to incorrect cutting or processing.

To prevent these defects, the following steps are suggested:

Quality Control: DKP sheet manufacturers should act meticulously at all production stages, from raw material analysis to final product inspection.

Proper Storage: DKP sheets should be preserved with protective coatings against moisture and rust.

Trained Personnel: Companies selling DKP sheets should train their staff on the transportation and storage of the materials.

What Advantages Do DKP Sheets Offer?

DKP sheet is preferred in different industries due to its many advantages. The main advantages are as follows:

Durability: DKP sheet is particularly durable against impacts and heavy loads due to its steel content.

Adaptation to Different Varieties: Solutions suitable for needs can be found among DKP sheet varieties. Many options are available, whether thin or thick, galvanized or stainless.

Economic Solutions: The appropriate production cost of DKP sheet offers a cost-effective alternative for project-based works.

Ease of Processing: It provides ease of installation and application due to its weldability and formability.

Companies selling DKP sheets can emphasize these advantages to customers and conduct a more effective marketing strategy.

What Should Companies Selling DKP Sheets Pay Attention To?

Key elements for the success of companies selling DKP sheets include:

Quality Product Supply: It is essential to cooperate with DKP sheet manufacturers to supply quality materials. Selling low-quality products can lead to a loss of reputation for the company.

Inventory Management: A full stock of DKP sheet varieties is necessary to meet different customer needs.

Training and Technical Support: Providing accurate information about DKP sheet properties and application areas to customers can boost sales.

Customer Satisfaction: Companies selling DKP sheets should prioritize customer satisfaction and pay attention to after-sales services.

As competition increases in the DKP sheet industry, companies offering various DKP sheet types at competitive prices by developing their marketing strategies will gain a significant advantage.

TR

TR