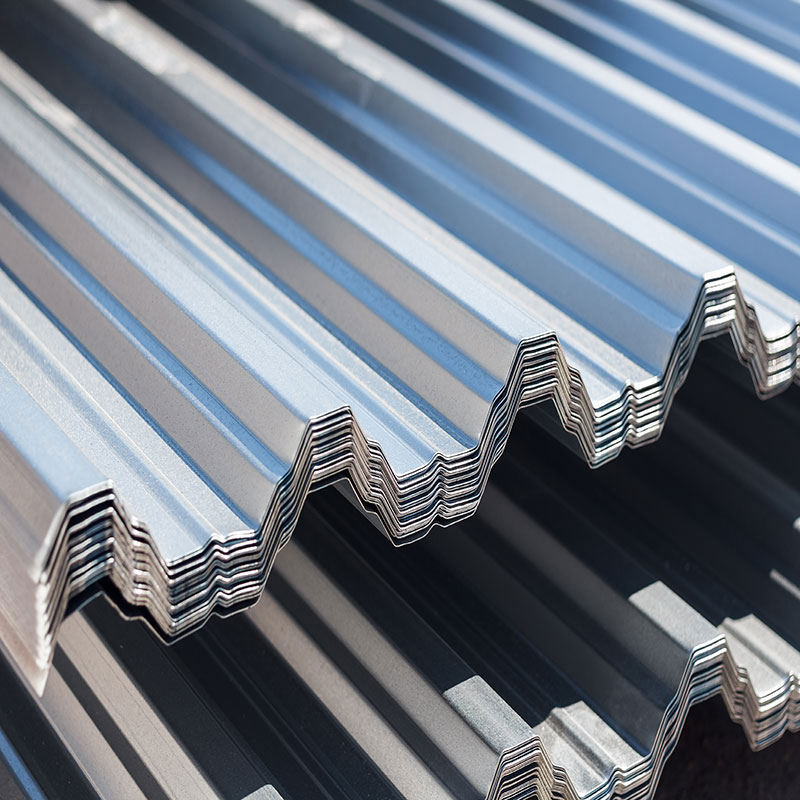

Trapezoidal sheets are materials widely preferred in the construction industry due to their durable and flexible structures. They can be used in roof covering, wall panels, and facade applications. With different thickness and color options, they offer aesthetic and functional solutions. Additionally, trapezoidal sheets are resistant to weather conditions and provide long-lasting use. They are both a practical and economical choice.

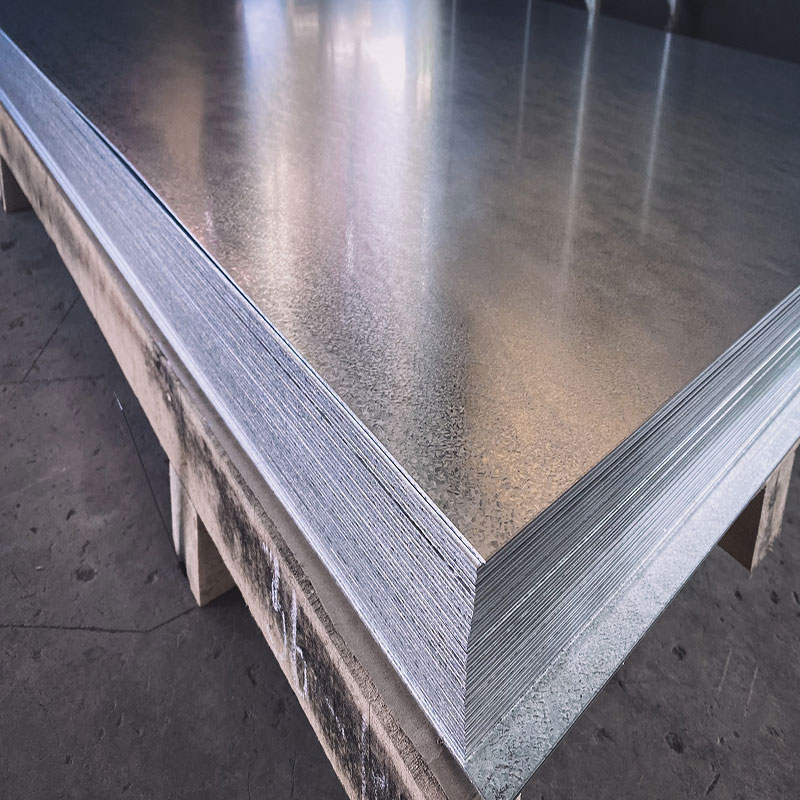

Trapezoidal sheet is a durable and long-lasting building material commonly used in the construction industry. Made from galvanized steel, these sheets have a trapezoidal shape due to their special form. This design not only gives the material an aesthetic appearance but also provides strength. Trapezoidal sheet is frequently preferred for roofing and facade cladding of buildings. Its high durability offers excellent protection against external weather conditions and its lightweight ensures ease of application.

Trapezoidal sheet can be used in various projects in different thicknesses and sizes. This allows users to choose according to their needs. When used as a roofing material, its structure facilitates the drainage of rainwater, minimizing the risk of leaks. Additionally, trapezoidal sheet is a commonly preferred cladding material in industrial areas such as warehouses, hangars, and factories.

There are many features that highlight trapezoidal sheet metal. These features make it ideal for various applications:

- High Strength: Its trapezoidal shape increases the sheet's load-bearing capacity and provides high durability.

- Lightweight: Despite being thin, its durable structure allows for easy transportation and installation of trapezoidal sheet metal.

- Long Life: Thanks to its galvanized coating, it is resistant to rust and corrosion. This ensures that trapezoidal sheet metal can withstand environmental conditions.

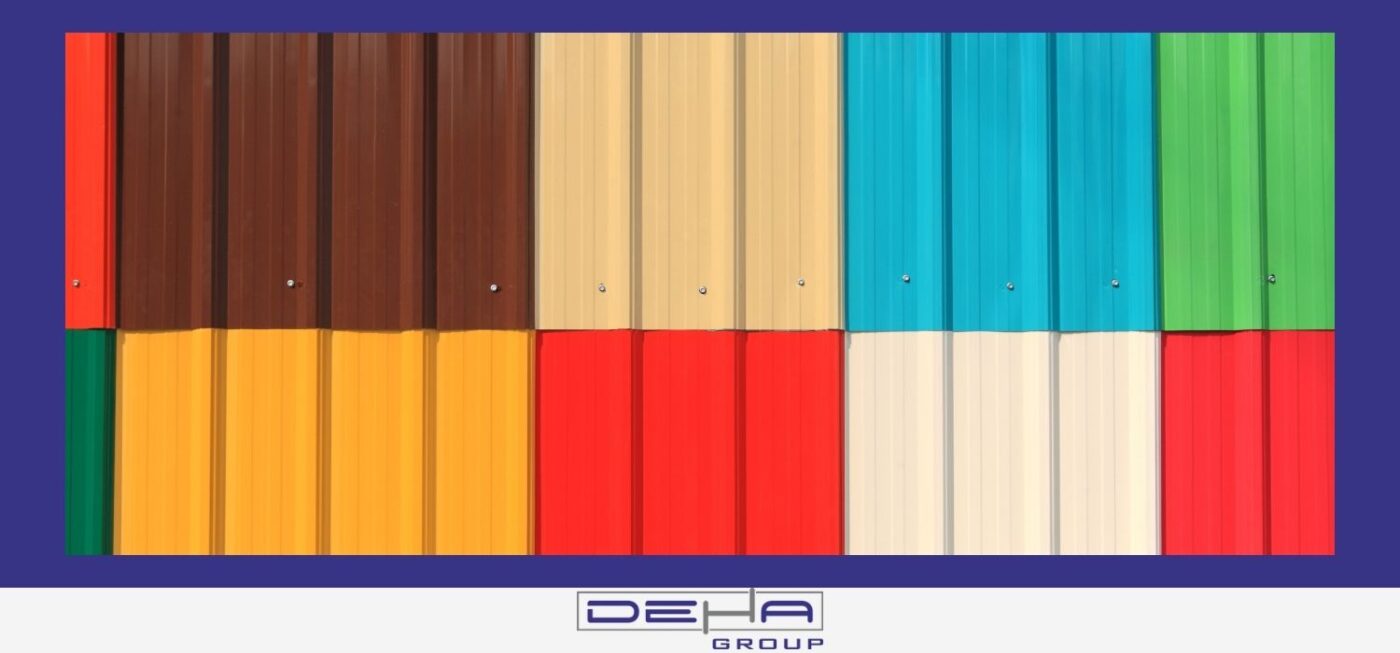

- Aesthetic Solutions: With different color and surface options, it can also be used decoratively. For example, it offers a sleek and industrial look in modern architecture.

- Economical: It is more cost-effective compared to other cladding materials, making it a budget-friendly option.

- Easy Installation: Its modular structure allows for easy installation. This feature reduces labor costs.

What Are the Uses of Trapezoidal Sheet?

Trapezoidal sheet is a versatile material used for various purposes. Its main areas of use and purposes are as follows:

Roof and Facade Claddings: Due to its durability and waterproof nature, trapezoidal sheet is commonly used in roof and wall claddings. It is frequently found in industrial facilities, warehouse buildings, and sports halls.

Prefabricated Structures: It is preferred in prefabricated structures due to its lightweight and durable nature, facilitating quick assembly and long-lasting structures.

Agricultural and Livestock Structures: In barns, warehouses, greenhouses, and other agricultural structures, trapezoidal sheet offers both an economical and practical option.

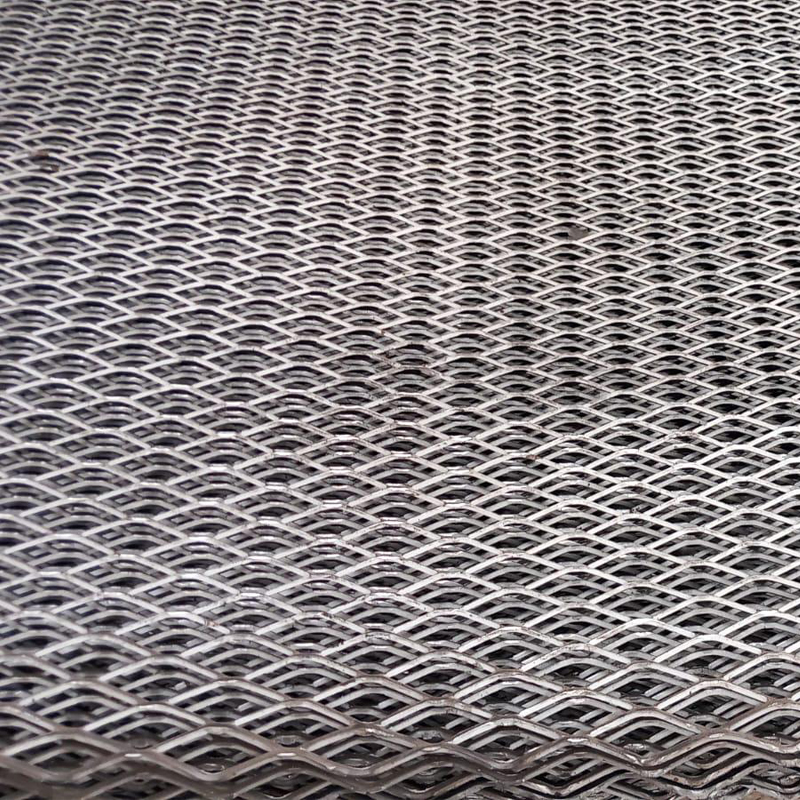

Security and Protection: Trapezoidal sheet is also used in temporary fences, barriers, and protection systems, providing long-lasting durability.

Decorative Purposes: Aesthetic trapezoidal sheet types offer decorative solutions in modern architecture. They can be used in interior and exterior designs with various color and pattern options.

What Are the Similarities Between Trapezoidal Sheets and Printed Sheets?

The similarities between trapezoidal sheets and printed sheets are as follows:

Material: Both types of sheets are generally made from steel and are durable materials suitable for outdoor use.

Corrosion Resistance: Trapezoidal and printed sheets are manufactured using corrosion-resistant materials like galvanized steel, ensuring their longevity.

Surface Treatment: Both types of sheets undergo special surface treatments to enhance durability and aesthetics. While trapezoidal sheets often have a wavy structure, printed sheets may have patterns, yet both feature surface coatings and designs.

Structural Applications: Both types of sheets are widely used in roofing, facade cladding, wall cladding, and other sectors. They are also utilized in industrial buildings.

Flexibility: Both trapezoidal and printed sheets exhibit a certain degree of flexibility and can be bent into desired shapes to suit different applications.

These similarities allow both types of sheets to be used for different aesthetic and functional requirements.

What Are the Types of Trapezoidal Sheets and How Are They Classified According to Their Uses?

Trapezoidal sheets are produced in various types and can be classified based on their usage. The main types of trapezoidal sheets are as follows:

Roof Trapezoidal Sheet:

Designed for roof claddings, offering high water resistance and durability.

Nowadays, roof trapezoidal sheets are used in a wide range of applications from modern homes to factory roofs.

Facade Trapezoidal Sheet:

Used for wall claddings, offering an aesthetic appearance with various color and pattern options.

It provides thermal performance, enhancing energy efficiency.

Galvanized Trapezoidal Sheet:

Offers long life with its corrosion-resistant galvanized coating.

Frequently preferred in coastal areas with high corrosion risks.

Painted Trapezoidal Sheet:

Offers decorative solutions and is produced in different colors.

Used as an aesthetic choice in modern architectural projects.

High-Strength Trapezoidal Sheet:

Used in roofing and fencing systems due to its high strength.

Sandwich Panel Trapezoidal Sheet:

Produced by placing insulation material between two trapezoidal sheets.

Used in roofs and cold storage facilities.

Role of Trapezoidal Sheet Manufacturers in the Market

Manufacturers in the trapezoidal sheet sector offer solutions tailored to customer needs by providing different sizes, shapes, and color options. Trapezoidal sheet manufacturers continue to produce more durable and aesthetic products by keeping up with technological innovations.

Trapezoidal sheet, with its durability, lightness, and longevity, is an indispensable material in various industrial and architectural projects. Thanks to trapezoidal sheet manufacturers, this material is produced to meet a wide range of needs and is widely used. Today, trapezoidal sheet continues to maintain its popularity by offering both economical and aesthetic solutions.

Factors Determining the Durability of Trapezoidal Sheet

Trapezoidal sheet is a durable and lightweight material widely used in construction and steel structure industries. The main factors determining its durability include material quality, production techniques, coating type, and profile design.

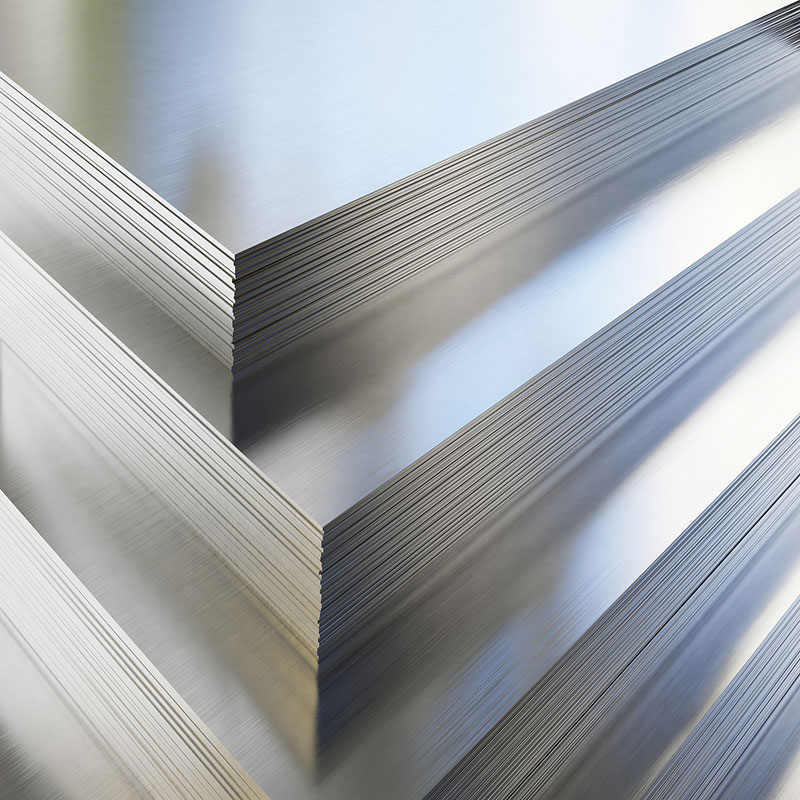

Material Quality: Trapezoidal sheet is generally made from galvanized steel. The thickness and quality of the steel directly affect its durability. When high-strength steel is used, the trapezoidal sheet becomes more long-lasting and durable.

Coating Type: The corrosion resistance of trapezoidal sheet is enhanced by the coating applied to it. Treatments like galvanizing, painting, or PVC coating are preferred. High-quality coating increases the product's resistance to environmental factors.

Profile Design: The wave form (profile) and geometry of the trapezoidal sheet affect its load-bearing capacity. Deeper profiles provide more strength and can carry heavier loads.

Production Techniques: The rolling and forming techniques applied during steel processing can affect the durability of the trapezoidal sheet. Modern and precise production techniques yield trapezoidal sheets with a more homogenous structure and predictable durability characteristics.

Advantages and Disadvantages of Using Trapezoidal Sheet

Trapezoidal sheet offers various advantages as a versatile material, but it also has certain disadvantages.

Advantages

Lightweight and Easy to Transport: Due to its lightweight nature, trapezoidal sheet can be easily transported and quickly installed.

Durability: Thanks to its galvanized coating, trapezoidal sheet is resistant to rust and is preferred in long-lasting structures.

Aesthetic Appearance: Available in different colors and profiles, trapezoidal sheet adds an aesthetic look to buildings.

Cost Efficiency: Offers an economical option both in terms of material and installation. Trapezoidal sheet manufacturers present many product alternatives to accommodate every budget.

DisadvantagesInsulation: Trapezoidal sheet alone does not provide sufficient insulation. Additional insulation materials are required.

Installation Precision: Incorrect installation can lead to water leaks or reduced structural strength.

Impact Sensitivity: Trapezoidal sheet surfaces are sensitive to hard impacts and can be easily scratched.

Position of Turkish Trapezoidal Sheet Manufacturers in the Sector

Turkey represents a significant market in the production of trapezoidal sheets. Local manufacturers hold an essential place in the sector through domestic market presence and export activities.

Local Production Capacity: Turkish trapezoidal sheet manufacturers produce with high-level technologies in modern facilities, allowing them to offer quality products at competitive prices.

Export Potential: Trapezoidal sheet manufacturers contribute to the Turkish economy by exporting to various countries, primarily in Europe.

Local Demand: Large projects in the construction sector ensure the widespread use of trapezoidal sheets in the local market. Manufacturers develop innovative solutions to meet this demand.

Main Methods Used in Trapezoidal Sheet Production

Trapezoidal sheet production is carried out using modern steel forming techniques.

Rolling: It starts with the steel being rolled into sheets of desired thickness. During rolling, the basic durability characteristics of the trapezoidal sheet are shaped.

Profiling: The trapezoidal sheet gains a wavy surface through shaping in special press machines. In this step, the profile depth and form are determined.

Coating: Coating processes like galvanizing or painting are applied to render the sheet corrosion-resistant.

Machines and Equipment Used for Creating Trapezoidal Sheets

Precision machines and equipment are used in trapezoidal sheet production.

Rolling Machines: Used to shape steel to correct thicknesses and dimensions.

Profile Forming Machines: These machines ensure the sheet assumes a trapezoidal form and operate rapidly and accurately.

Coating Facilities: Special equipment is used for galvanizing and painting processes, ensuring the trapezoidal sheet is durable and aesthetic.

Cutting Machines: Trapezoidal sheets are cut to desired lengths and dimensions. Cutting machines ensure precise measurement of products.

Trapezoidal sheet plays a vital role in modern construction projects as a strong and versatile material. Turkish manufacturers, with innovative production methods and competitive pricing, effectively serve both local and international markets.

TR

TR