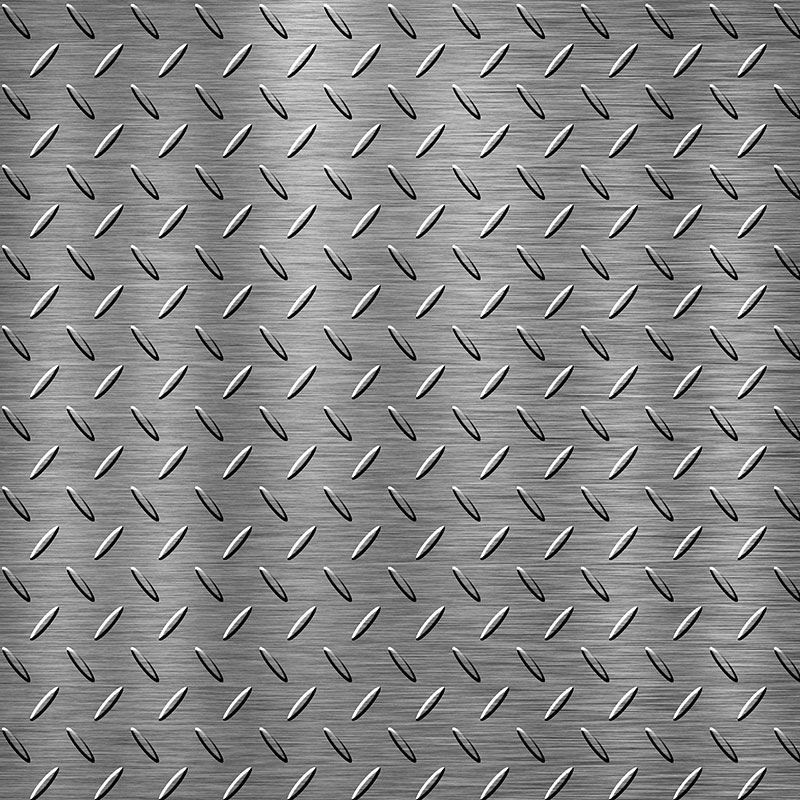

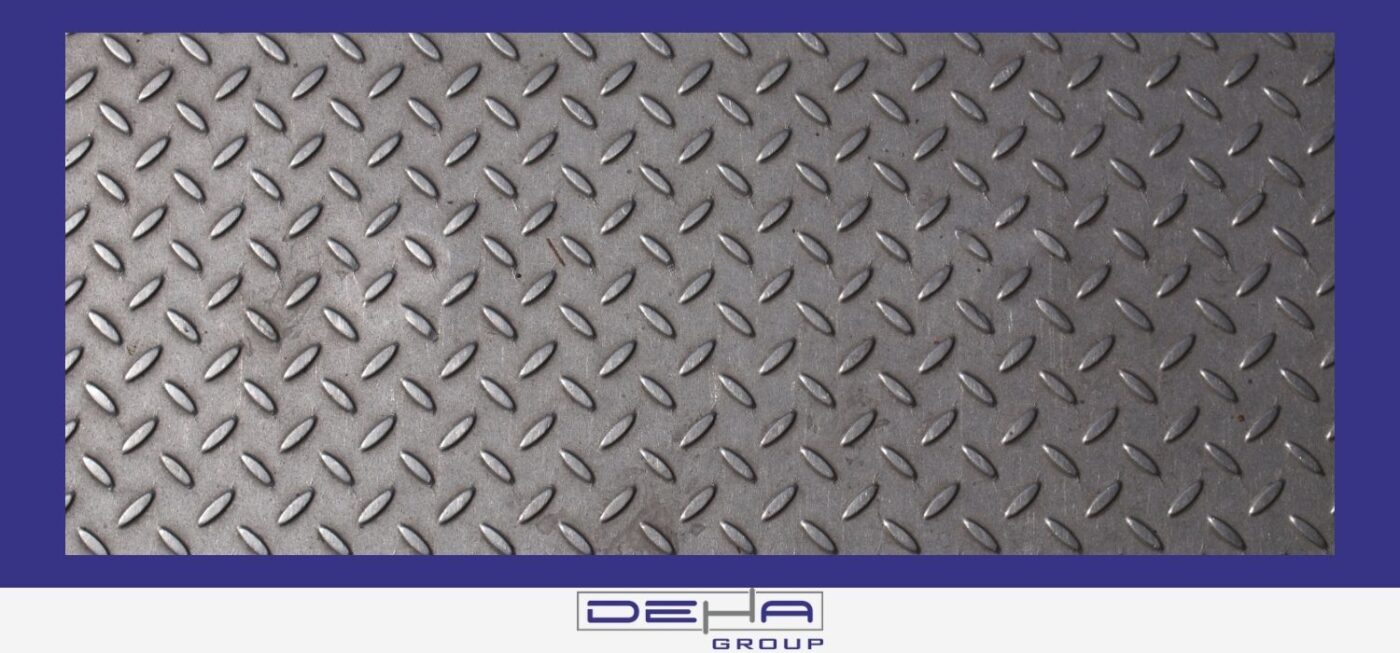

Teardrop patterned sheets are a type of material that stands out with both its aesthetic appearance and functionality. They are often preferred for flooring, stair steps, and industrial areas due to their non-slip surface feature. These sheets, made of aluminum, steel, or galvanized material, are noteworthy for their durability and long-lasting structure. In decorative applications, they offer a modern and stylish appearance.

Tear drop pattern metal sheet is a type of sheet known for its embossed patterns in the shape of teardrops, commonly recognized for its anti-slip properties. These types of sheets are preferred in many industries not only for their aesthetic appearance but also for their functionality. Among patterned sheets, the tear drop pattern metal sheet stands out with its durability and long-lasting structure. It is especially used in industrial areas to enhance safety and minimize the risk of slipping.

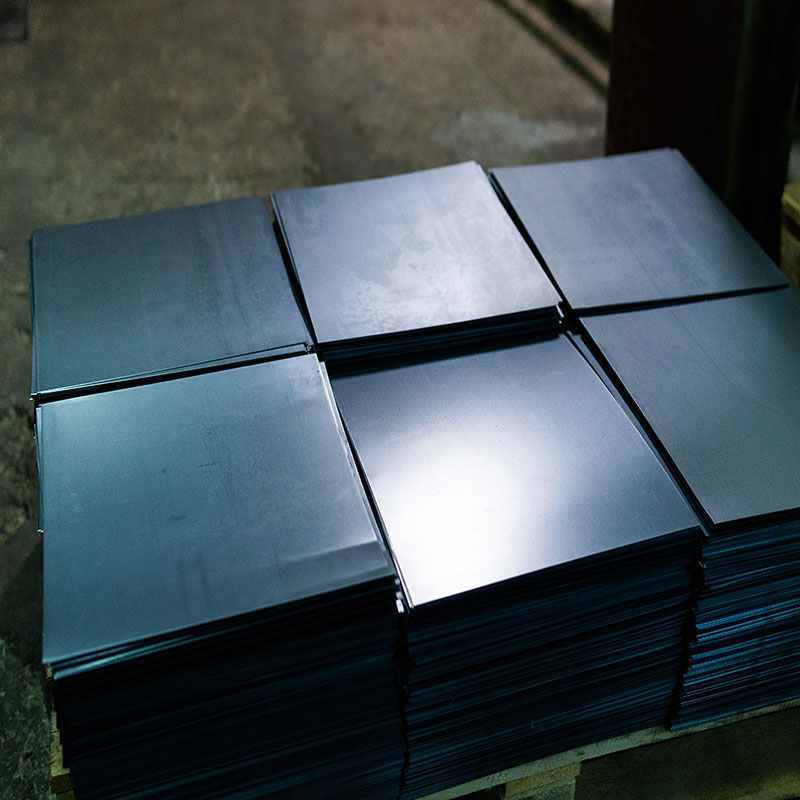

This type of sheet is typically produced from steel, aluminum, or galvanized materials and provides extra grip thanks to its embossed surface. Therefore, it has a wide range of applications both indoors and outdoors. During the production process, sheet metals are shaped with the help of special machines to have a teardrop pattern. These patterns provide both a decorative appearance and increased functionality.

One of the most notable features of tear pattern sheets is their non-slip surface. In addition, this type of sheet offers several advantages:

Non-Slip Surface: The tear patterns create extra friction on the surface, thereby reducing the risk of slipping.

Durability: Because they are made of steel, aluminum, or galvanized material, they are resistant to heavy loads.

Longevity: Patterned sheets with a non-corrosive structure are resistant to harsh weather conditions.

Lightweight: Tear pattern sheets produced using aluminum material provide easy portability with their lightweight structure.

Easy Cleaning: Thanks to their embossed surface, they do not retain dirt and stains and can be cleaned easily.

These features make tear pattern sheets an indispensable material in many applications.

Applications of Tear Drop Patterned Sheet

Tear drop patterned sheet is used in a variety of industries due to its durability and non-slip feature. Here are some common application areas for this type of sheet:

Industrial Flooring: Used to prevent slipping on floors in factories, workshops, and warehouses.

Transport and Logistics: Frequently preferred for truck beds, trailer floors, and loading ramps.

Stairs and Docks: Ensures safety on stair treads and docks due to its non-slip surface.

Decorative Uses: Can also be used for decorative purposes in interior designs due to its aesthetic appearance.

Ventilation and Heating Systems: The sheet's durable structure allows it to be used in equipment like ventilation ducts.

Shipbuilding and Maritime Industry: Used on ship decks and maritime equipment due to its resistance to salty water.

Tear drop patterned sheets combine durability and aesthetics, making a significant impact in these areas. Their wide range of uses ensures they have an important place in every industry.

What Are the Advantages and Disadvantages of Tear Drop Patterned Sheets?

Advantages:

Provides Safety: Offers safe usage thanks to its non-slip structure.

Diverse Material Options: Offers various material options like aluminum and steel to meet different needs.

Aesthetic Appearance: Embossed patterns give it a modern and aesthetic look.

Easy Installation: Its lightweight and workable structure make installation very easy.

Durability: Offers long-lasting use with high load-bearing capacity and rust-resistant features.

Disadvantages:

Cost: The production process may be more costly compared to other types of sheets.

Limited Pattern Variety: Tear drop patterned sheets are limited to a specific pattern, which can be a disadvantage for certain designs.

Surface Wear in Intense Use: Surface wear may occur with prolonged heavy use.

Technical Features of Tear Drop Patterned Sheets

Tear drop patterned sheets are metal sheets with embossed tear drop patterns on them. These special patterns allow the sheet to have a non-slip surface. This feature makes it preferred in areas where safety is a priority. Here are the prominent technical features of tear drop patterned sheets:

Non-Slip Surface

The most important advantage of tear drop patterned sheets is providing a non-slip surface. This feature offers safe usage in flooring and platform applications.

High Durability

These sheets, often made from aluminum, steel, or galvanized steel, are highly resistant to wear and impact. Therefore, they can also be used in heavy load-bearing areas.

Aesthetic Appearance

Tear drop patterned sheet stands out as a decorative material as well. Offering a modern and stylish appearance, it can be used in both industrial and interior spaces.

Easy Workability

Patterned sheets have features that make them easy to cut and shape. This allows the sheets to be easily adapted to different projects.

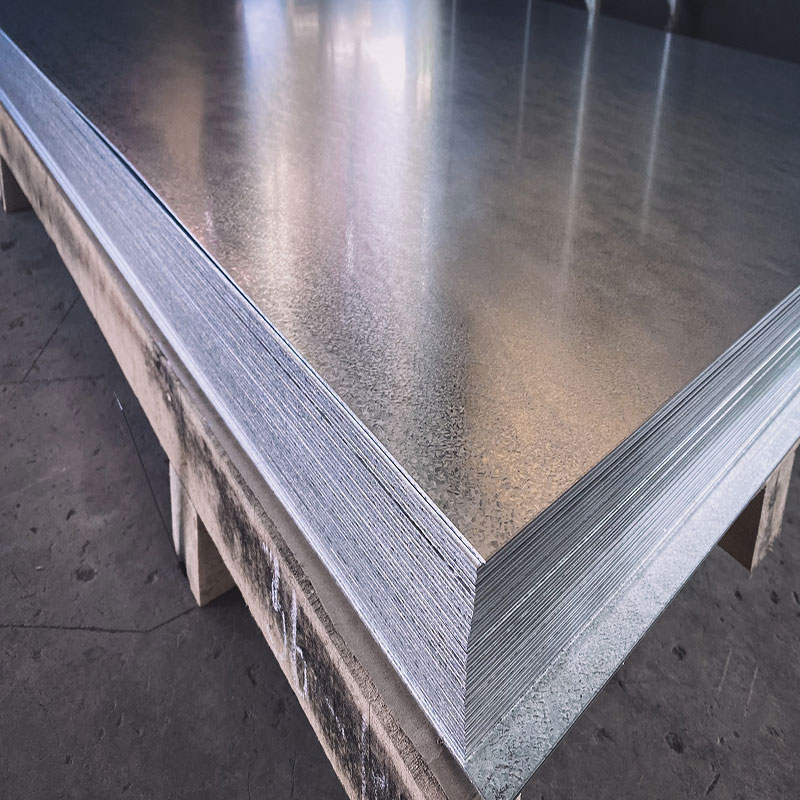

Corrosion Resistance

Especially, galvanized tear drop patterned sheets show high resistance against rust. This feature makes them an ideal choice for outdoor use.

How Is Tear Drop Patterned Sheet Produced?

Production of tear drop patterned sheets is carried out through a special embossing and rolling process. The production process includes the following steps:

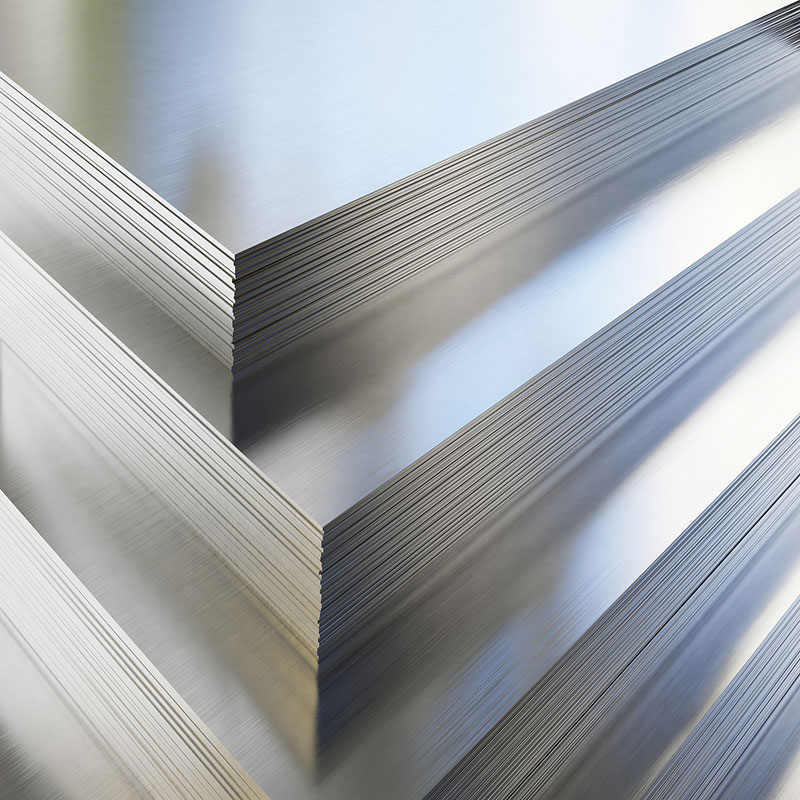

Raw Material Selection

Typically, aluminum, carbon steel, or galvanized steel is preferred in the production of tear drop patterned sheets. These materials have ideal properties in terms of both strength and workability.

Rolling and Embossing

In the production of patterned sheets, hot or cold rolling methods are used. During this process, the metal sheet is thinned to a certain thickness and then special tear drop patterns are applied to its surface.

Surface Treatments

To increase the sheet's corrosion resistance, galvanizing or special coating processes are carried out. This process ensures the product is long-lasting.

Cutting and Sizing

The produced tear drop patterned sheets are cut and packaged according to desired dimensions. At this stage, sizes and shapes suitable for customer needs are provided.

Varieties of Tear Drop Patterned Sheets

Tear drop patterned sheets are divided into different types based on material type and application areas. Here are the most common types:

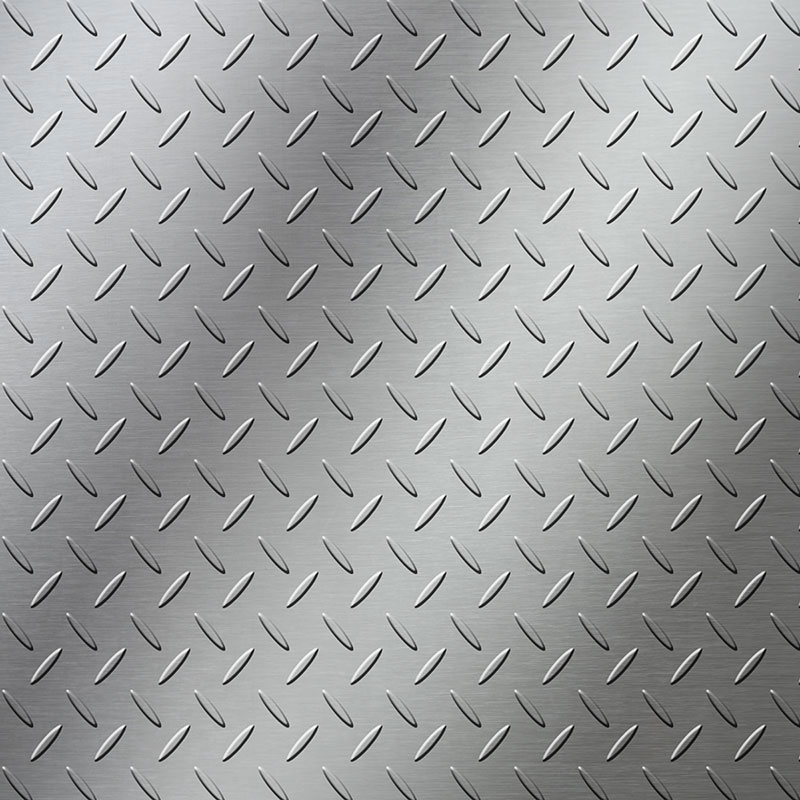

Aluminum Tear Drop Patterned Sheet

Notable for its lightness, aluminum patterned sheets are often preferred in decorative projects due to their ease of transport and aesthetic appearance. Furthermore, with their non-rust properties, they offer long-lasting use in outdoor areas.

Galvanized Steel Tear Drop Patterned Sheet

Known for its resistance to corrosion, galvanized sheets are typically used in heavy industry and construction projects. These sheets stand out with their durability.

Stainless Steel Tear Drop Patterned Sheet

Stainless steel patterned sheets, which have a durable and elegant appearance, are frequently preferred in areas requiring hygiene, such as the food and health sectors.

Carbon Steel Tear Drop Patterned Sheet

Known for its high strength, carbon steel sheets are used on floors carrying heavy loads and in industrial equipment.

Usage Areas of Tear Drop Patterned Sheets

Patterned sheets are used in many different industries due to their non-slip surfaces and durability:

Floor Coverings: They are preferred for safety in factories, warehouse areas, and truck beds.

Stair Treads: Provide safe use due to their non-slip structure.

Decoration: With their aesthetic appearance, they can be used in furniture design and wall coverings in interior spaces.

Industry and Construction: They are commonly used in platforms, ramps, and construction machine equipment.

What Are the Economic Advantages of Tear Drop Patterned Sheets?

Tear drop patterned sheet has a wide range of use in the construction and industrial sectors. This material stands out with both its durability and aesthetic appearance. Its economic advantages are quite significant.

Firstly, tear drop patterned sheets are long-lasting. Their resistance to rust keeps the maintenance costs of these sheets at a minimum. Additionally, their patterned structures have anti-slip properties. This not only provides a safe working environment but also reduces workplace accidents, indirectly lowering costs.

The lightweight nature of these sheets makes transportation and installation easier. They provide cost advantages with less need for labor and equipment. Their low production costs and recyclable nature also make tear drop patterned sheets economically attractive.

Recommendations for Companies Producing Tear Drop Patterned Sheets

Companies manufacturing patterned sheets should focus on offering a wide product range that meets customer needs. Tear drop patterned sheet is frequently used, especially in flooring and stair treads. Therefore, offering various size and thickness options is important.

Additionally, prioritizing quality control in the production process increases customer satisfaction. Using high-quality materials and modern production technologies will enhance the company's competitive power in the industry. In marketing strategies, highlighting the anti-slip, durable, and economic features of tear drop patterned sheets can create a positive impact on the target audience.

Load-Bearing Capacities of Tear Drop Patterned Sheets

The load-bearing capacities of tear drop patterned sheets vary depending on the sheet's thickness and material type. Typically, due to their durable structures, they are frequently used in applications requiring heavy load-bearing. These patterned sheets can be safely used in flooring, load-bearing platforms, and industrial facilities.

Choosing the right material to increase the sheet's load-bearing capacity is very important. Patterned sheets made from high-carbon steel or galvanized steel provide durability and longevity. Additionally, the surface patterns' anti-slip feature enhances safety during transport.

Tear drop patterned sheets offer both economic and functional advantages. Producers can stand out in the industry by effectively promoting the benefits of these sheets and prioritizing product quality.

TR

TR