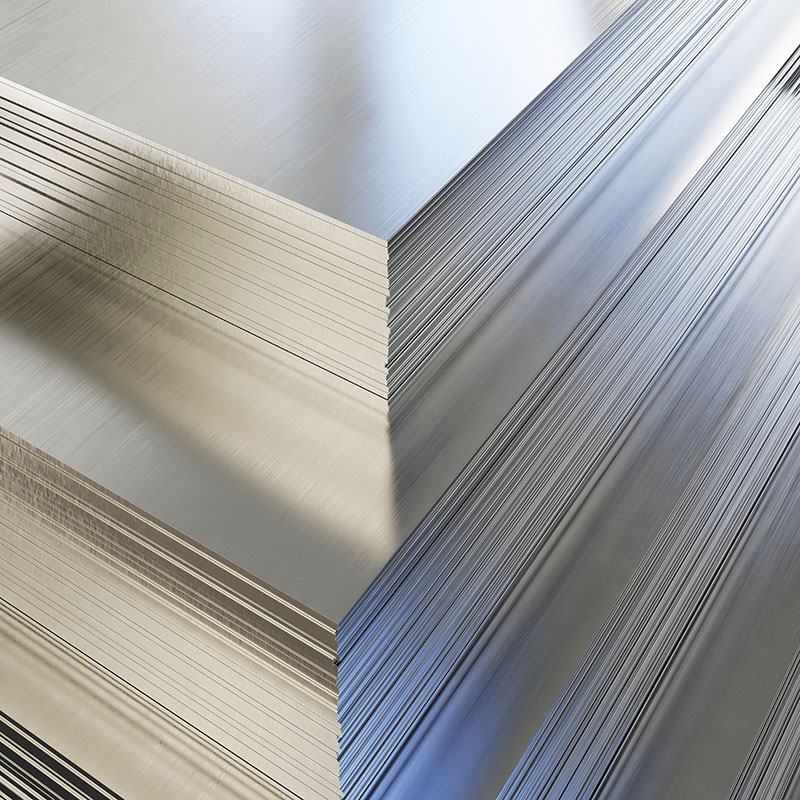

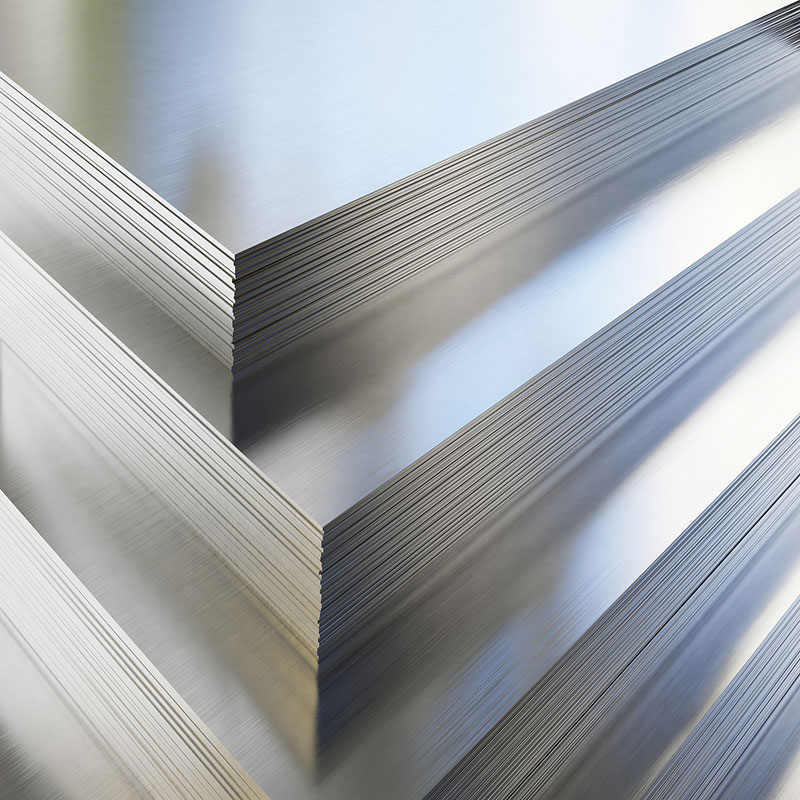

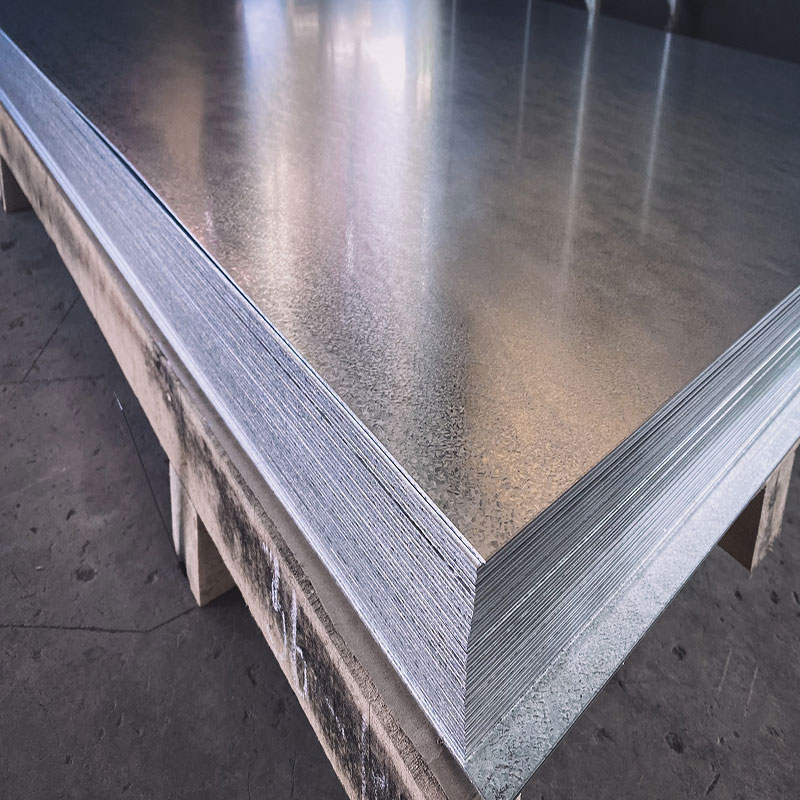

Galvanized sheets are durable materials produced by applying a protective zinc coating to the surface of steel sheets. This process increases the sheets' resistance to corrosion and ensures long-lasting use. Frequently preferred in the construction, automotive, white goods, and furniture industries, galvanized sheets offer both aesthetic and functional advantages. They are ideal for effective solutions against rust.

Galvanized sheets are products obtained by coating the surface of steel sheets with zinc. The zinc coating protects the steel from environmental effects and significantly slows down the rusting process. Thanks to these properties, galvanized sheets are safely preferred for both indoor and outdoor uses. Additionally, the galvanizing process enhances the durability of the sheet while also providing an aesthetic appearance. Since the zinc coating is tightly bonded to the steel's surface, it ensures the sheet's longevity.

The main material of galvanized sheets is steel. Steel, due to its high strength and workability, provides an ideal base for the galvanizing process. The zinc coating on the surface of the steel provides the main feature of galvanized sheets, which is corrosion resistance. The zinc coating not only physically covers the steel but also offers electrochemical protection. Thus, the steel is protected against environmental factors such as water, moisture, and oxygen.

The zinc used in galvanized sheets is one of the most important factors determining the quality of the coating. When zinc is evenly distributed on the surface of the steel, the product's longevity and durability increase.

In Which Sectors Are Galvanized Sheets Used?

Galvanized sheets are used in a wide range of sectors due to their durability and functionality. Here are some of the areas where these sheets are commonly preferred:

1. Construction Industry

Galvanized sheets are used in construction for applications such as roofing, wall panels, water tanks, and drainage systems. Their corrosion-resistant structure provides a long-lasting solution, especially for outdoor use.

2. Automotive Industry

Galvanized sheets are widely used in vehicle bodies, chassis components, and exhaust systems. The zinc coating prevents rusting of vehicle parts while offering a lightweight structure.

3. Home Appliances and Electronics

Galvanized sheets are commonly used in home appliances such as refrigerators, washing machines, and ovens. This material also stands out in electronics for its durability and aesthetic appearance.

4. Agriculture and Livestock

Due to their durability and resistance to environmental effects, galvanized sheets are widely used in agricultural machinery, irrigation equipment, and animal shelters.

5. Energy and Telecommunications

In solar energy panels and telecommunications towers, galvanized sheets are a critical material because of their strength and resistance to rust.

Methods Used in the Production of Galvanized Sheets

The production process of galvanized sheets varies according to the method used. The most common galvanizing methods are:

1. Hot-Dip Galvanizing

This method is one of the most commonly used techniques in the production of galvanized sheets. The steel sheet is dipped into a bath of molten zinc. During this process, the zinc adheres tightly to the steel surface, creating a durable coating. The hot-dip method increases the corrosion resistance of the sheet and provides a homogeneous coating over large surfaces.

2. Electro Galvanizing

Electro Galvanizing is a method where zinc coating is applied to the steel surface using an electric current. This technique is preferred for obtaining a thinner and smoother coating. Electro Galvanizing is used in delicate applications and areas requiring high aesthetic quality.

3. Thermal Spray Coating

The thermal spray method is carried out by spraying zinc in a thin layer onto the steel surface. This method is an effective solution in cases where local galvanizing is required.

4. Metal Coating

In the metal coating method, zinc is applied as a thin film layer on the steel surface. This technique is used in applications requiring a lighter coating.

Galvanized sheets have become an indispensable material in many fields, from construction to automotive, home appliances to agriculture, due to their durability and aesthetic features. The perfect harmony of steel and zinc materials offers long-lasting solutions. Moreover, the variety of galvanizing methods allows for production according to different needs. With these features, galvanized sheets are one of the cornerstones of modern industries and construction projects.

Advantages of Galvanized Sheets

Galvanized sheets are favored by many sectors due to their numerous advantages. Here are some of the standout benefits:

Superior Resistance to Rust

Galvanized sheets exhibit high resistance to rust caused by the effects of moisture, water, and oxygen thanks to their zinc coating. This feature provides a significant advantage, especially for materials used outdoors.

Long-Lasting Use

The galvanizing process protects the steel by covering its surface with a zinc layer, extending the lifespan of galvanized sheets and minimizing maintenance costs.

Economical and Environmentally Friendly

Galvanized sheets offer a cost-effective solution due to their long-lasting durability. Furthermore, the galvanizing process is an environmentally friendly method, and these sheets are recyclable.

Aesthetic Appearance

The zinc coating gives the sheets a shiny and smooth surface, making galvanized sheets a popular choice for projects where aesthetic appearance is important.

Suitability for Various Applications

Galvanized sheets are suitable for use in diverse sectors such as construction, automotive, home appliances, energy, and agriculture. They meet many needs in terms of both durability and workability.

Why Are Galvanized Sheets Resistant to Rust?

The fundamental reason for the rust resistance of galvanized sheets is the zinc coating process. Zinc has a lower oxidation potential compared to iron or steel. The zinc layer physically covers the sheet surface, preventing contact with moisture and air. Even if the zinc coating oxidizes over time, it retains its protective properties and continues to shield the sheet from rust. Zinc provides "cathodic protection" on the sheet. This means that the zinc coating prevents rusting of the sheet even if scratches or damage occur on any part of the sheet.

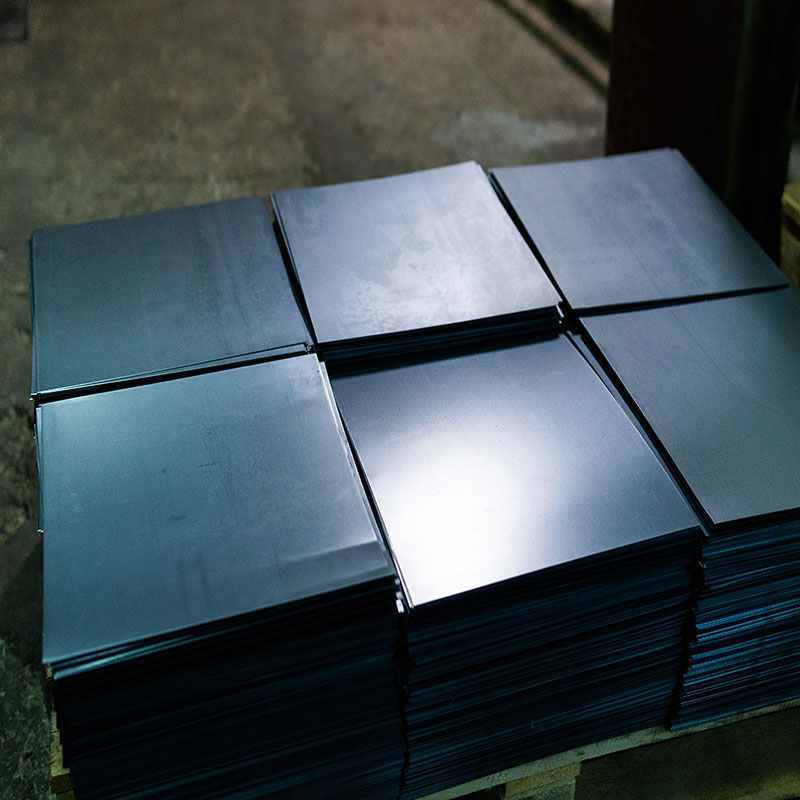

Differences Between Galvanized Sheets and DKP Sheets

Galvanized sheets and DKP sheets are different types of steel produced for different purposes. The main differences between them are:

Coating Status:

Galvanized Sheets: Coated with zinc, giving them high resistance to rust.

DKP Sheets: Uncoated, making them more susceptible to corrosion.

Usage Areas:

Galvanized Sheets: Used in outdoor applications, and in the white goods, automotive, and construction industries.

DKP Sheets: Preferred in products requiring deep drawing and shaping, such as furniture and kitchenware.

Surface Quality:

Galvanized Sheets: Have a shiny and smooth surface due to the zinc coating.

DKP Sheets: Have a more matte and flat surface.

Durability:

Galvanized Sheets: Have high corrosion resistance, making them suitable for harsh weather conditions.

DKP Sheets: Softer and more suitable for shaping, but have lower corrosion resistance.

Both types of sheets offer different advantages depending on the need, and the right choice depends on the intended use.

In Which Sectors Are Galvanized Sheets Preferred?

Galvanized sheets are heavily preferred in many sectors due to their resistance to corrosion and long-lasting usage. They have a wide range of applications, from the construction industry to automotive, white goods production, and energy plants. In the construction industry, galvanized sheets are frequently used in roofing, facade systems, and structural components. In the automotive industry, they are preferred in vehicle body parts for offering both durability and lightness. In white goods production, these sheets are used to prevent rusting in products such as washing machines, refrigerators, and ovens. In addition, in the energy sector, the durability of galvanized sheets is prominent in solar panels and power poles.

How Is the Galvanizing Process Done?

The galvanizing process involves the zinc coating of metal surfaces to protect against corrosion. This process is typically done using the hot-dip method. First, the metal surface is cleaned and rid of all impurities. Then, the metal is submerged in a bath of molten zinc. During this process, the zinc forms a chemical bond with the metal surface, creating a protective coating layer. The hot-dip galvanizing method is the most commonly used because it provides a durable and long-lasting coating. Alternatively, an electro-galvanizing method may also be used, where an electric current is used to coat the metal surface with zinc.

How Can the Durability of Galvanized Sheets Be Increased?

Various methods can be used to increase the durability of galvanized sheets. First, the quality of the zinc used in the production of sheets is crucial. High-quality zinc coating provides longer-lasting protection. Additionally, ensuring the galvanizing process is correctly done provides a uniform and sufficient coating thickness. The environment where galvanized sheets are used also affects their durability. Additional protective coatings can be applied for sheets used in humid and salty environments. For instance, painting or special chemical coating methods can extend the lifespan of galvanized sheets. Regular maintenance and cleaning procedures are also effective methods for enhancing the durability of sheets.

Galvanized sheets stand out as an indispensable material in many sectors due to their corrosion resistance and versatile usage features. With the right production and maintenance processes, the durability of these sheets can be further enhanced.

TR

TR