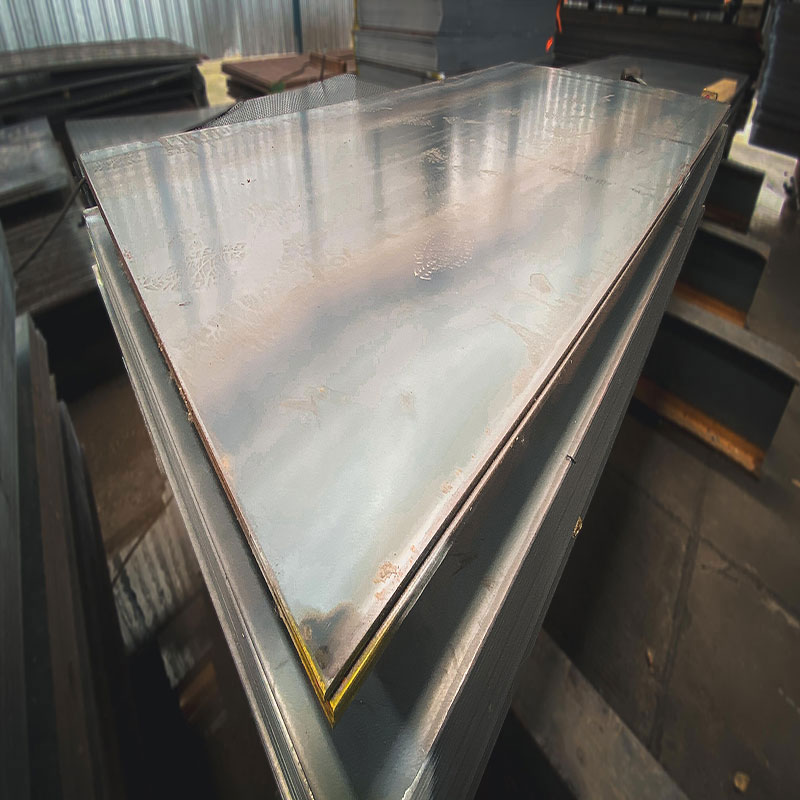

Sheet metals are flat and thin metal materials commonly used in the industrial and construction sectors. These sheets, usually made of steel, aluminum, or stainless steel, are preferred for their durability and workability. While they are used in areas like roofing, automotive, and furniture production, they offer suitable solutions for projects with different thickness and size options. Additionally, they are suitable for processes such as cutting, bending, and welding.

Sheet metal can be described as flat metal plates commonly used in the metal industry and typically made from steel. Notable for its flat and wide surface structure, sheet metal can be produced in various thicknesses and sizes. These products are utilized in many fields ranging from industry to construction, from automotive to furniture sectors. The dimensions of sheet metal can be tailored specifically to the requirements of a project, which makes it stand out as a versatile material.

Sheet metals are known for their high strength, durability, and workability. They can be shaped through different processes and cut to desired sizes. Sheet metals, made more resistant to corrosion through various coating methods, offer both aesthetic appeal and functionality.

Sheet metal types differ based on production method, coating type, and intended use. Here are the most common sheet metal types:

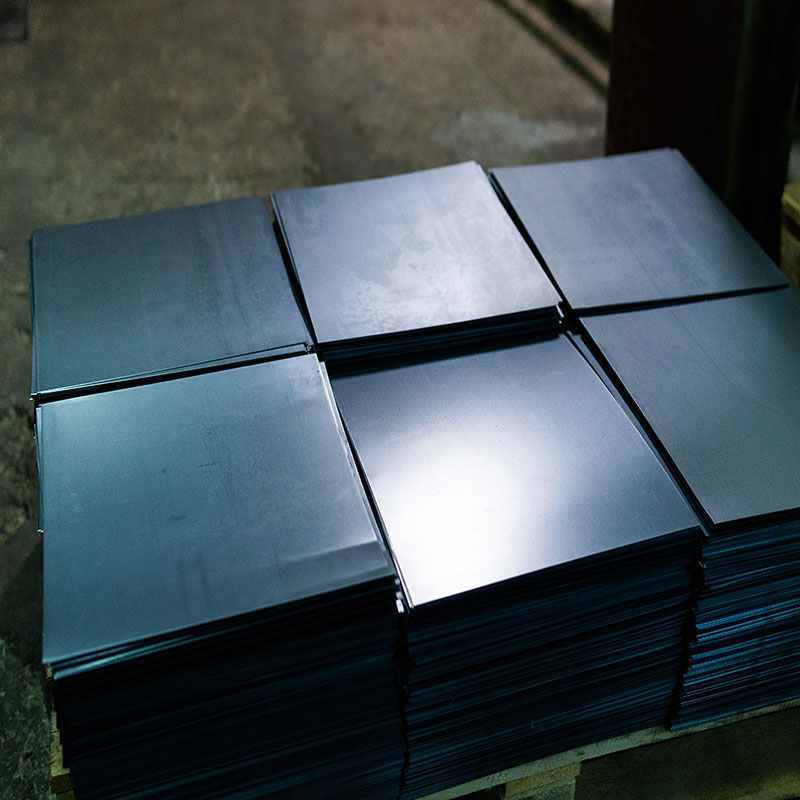

Hot Rolled Sheet Metals:

Sheet metals shaped at high temperatures have a durable and hard structure. They are widely used in the construction and machinery sectors.

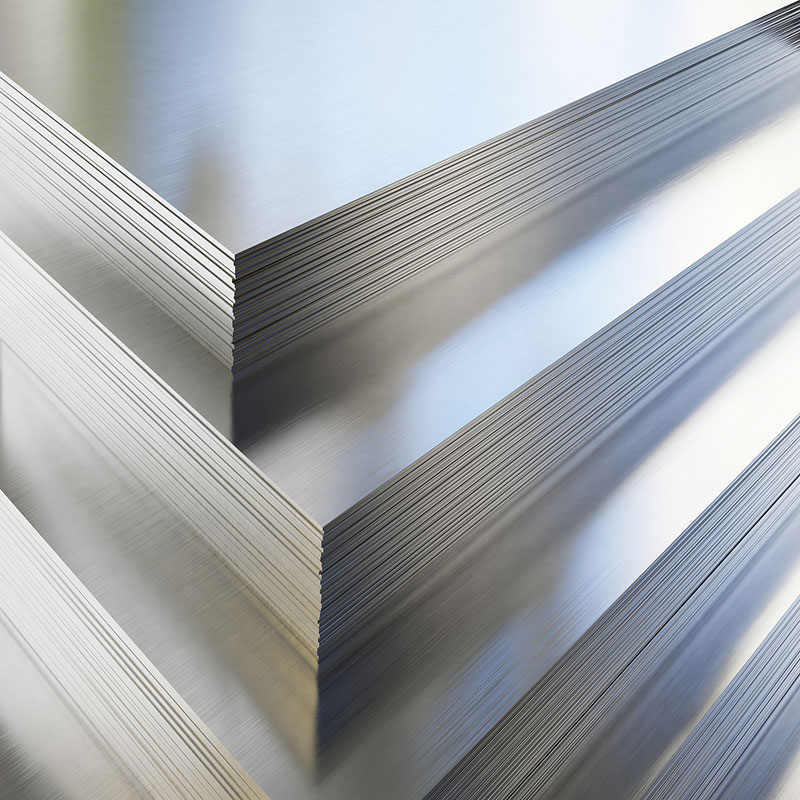

Cold Rolled Sheet Metals:

Preferred for applications that demand a smoother and thinner surface. They are used in the decoration and automotive sectors.

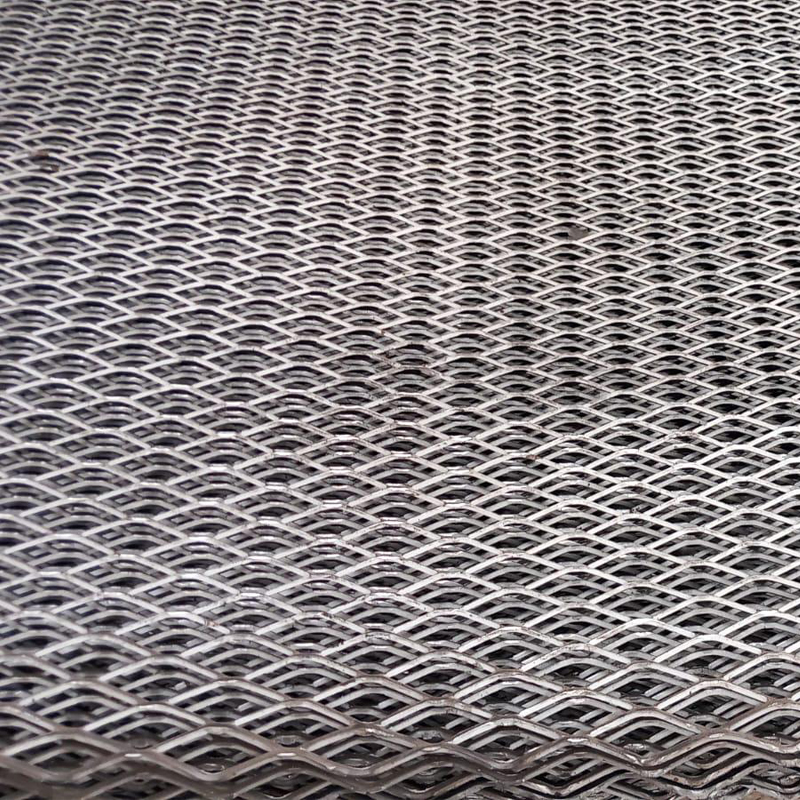

Galvanized Sheet Metals:

These are types made resistant to corrosion. Used in fences, roofing systems, and outdoor applications.

Stainless Sheet Metals:

Due to their steel components, they are extremely resistant to rust. Commonly preferred in the food industry and kitchen equipment.

Paintable Sheet Metals:

Used in projects requiring an aesthetic appearance. They offer various color options.

Where Are Sheet Metals Used?

The areas of use for sheet metal are extremely wide. This broad range of applications stems from the versatility of the material. Here are the main areas where sheet metal is used:

Construction Sector:

Sheet metal is used as a fundamental material in building and infrastructure projects. Steel constructions are commonly used in roof covering and wall panel systems as well.

Automotive Industry:

Sheet metal is used in vehicle bodies, chassis systems, and engine parts. Its light yet durable structure makes it an indispensable part of the automotive industry.

Furniture Sector:

Sheet metal is frequently used in metal furniture designs. It is preferred in the production of items such as cabinets, tables, and shelf systems.

Industry and Machinery:

Sheet metal varieties can be used in many different areas in machine components, equipment cases, and industrial facilities.

Decoration and Architectural Design:

Thanks to its aesthetic and durable structure, sheet metals are preferred in decoration projects. It is widely used in modern buildings for both interior and exterior cladding.

Rolling Methods in Sheet Metal Production

One of the most commonly used methods in sheet metal production is rolling. Rolling describes the process of shaping metals under hot or cold conditions. Here are the details of these methods:

Hot Rolling:

When the hot rolling method is used in sheet metal production, the metal plate is processed at high temperatures to achieve the desired thickness and dimensions. This method is suitable for obtaining thicker sheet metal sizes.

Cold Rolling:

The cold rolling method is applied at lower temperatures, resulting in thinner and smoother surfaces. This method is generally preferred for decorative and precision projects.

Coating Rolling:

With this method, a protective coating is added to the sheet metals. The coating increases the durability of the sheet metal and reduces the risk of corrosion.

Sheet Metal Forming

Sheet metal stands out as an indispensable material in modern industrial applications. Used in construction, automotive, home appliances, energy, and many other sectors, it is preferred for its durability, versatile properties, and economic efficiency. Made from materials like steel or aluminum, sheet metal can meet various needs through forming methods.

The Importance of Sheet Metal in Construction and Building Sector

Sheet metal emerges as one of the fundamental materials in the construction and building sector. It is extensively used in applications such as roof coverings, wall panels, suspended ceiling systems, and facade claddings. Among the main reasons for this are the material's durability, eco-friendliness, and ease of processing.

The use of sheet metal allows for time and cost savings in projects. Especially in prefabricated buildings, the material's lightness and durability enable projects to be completed more quickly. Additionally, as an eco-friendly material, its contribution to reducing the carbon footprint is noteworthy.

Turkey's Role and Potential in Sheet Metal Export

Turkey holds a significant position in the world regarding sheet metal production and export. Being among the leaders in steel production in Europe, the country also continuously develops its sheet metal production sector.

One of Turkey's advantages in sheet metal export is its geopolitical position. Proximity to European, Middle Eastern, and African markets keeps export costs low. Likewise, local manufacturers' use of modern technology and high-quality production standards increase competitiveness in international markets.

However, to elevate this success to higher levels, innovation, R&D investments, and pursuit of new markets are essential. Turkey's potential in sheet metal export is directly linked to future advancements in the steel sector.

The Future of Sheet Metal Production

With the Industry 4.0 revolution, the impact of digital technologies in sheet metal production is increasingly growing. Innovations like automation, robotic systems, and data analytics are making production processes more efficient. Simultaneously, renewable energy and recycling-focused efforts contribute to reducing the environmental impacts of steel production.

In sheet metal production, the use of nanotechnology and lightweight materials are among the prominent trends of the future. These innovations will make the material much more durable, lightweight, and functional. For example, the use of lighter sheet metals in the automotive sector will improve fuel efficiency while reducing carbon emissions.

What Are the Dimensions of Sheet Metal?

Sheet metal dimensions can vary depending on the application areas and needs. Standard dimensions generally cover thickness, width, and length values. The following dimensions are widely used:

Thickness: It can vary between 0.2 mm and 20 mm. Thin sheets are usually preferred as part of decorative applications or delicate architectural details, while thicker sheets are used in applications requiring durability.

Width: Standard dimensions range between 600 mm and 2500 mm.

Length: Sheets are typically cut in dimensions ranging from 1000 mm to 6000 mm. However, production can be done in special sizes according to needs.

These dimensions can vary depending on different types of steel and processing methods, so making project-specific choices is important.

Advantages of Sheet Metal

The use of sheet metal provides cost-effective and eco-friendly solutions in many sectors. Some of the advantages of this material are:

Lightweight and Durability: Sheet metals offer very high durability despite being lightweight.

Flexibility: It can be easily processed and transformed into different forms.

Corrosion Resistance: It is resistant to rusting thanks to coating techniques.

Aesthetic Solutions: It is an ideal material for decorative applications.

Sustainability: It is recyclable and has a minimal impact on the environment.

TR

TR