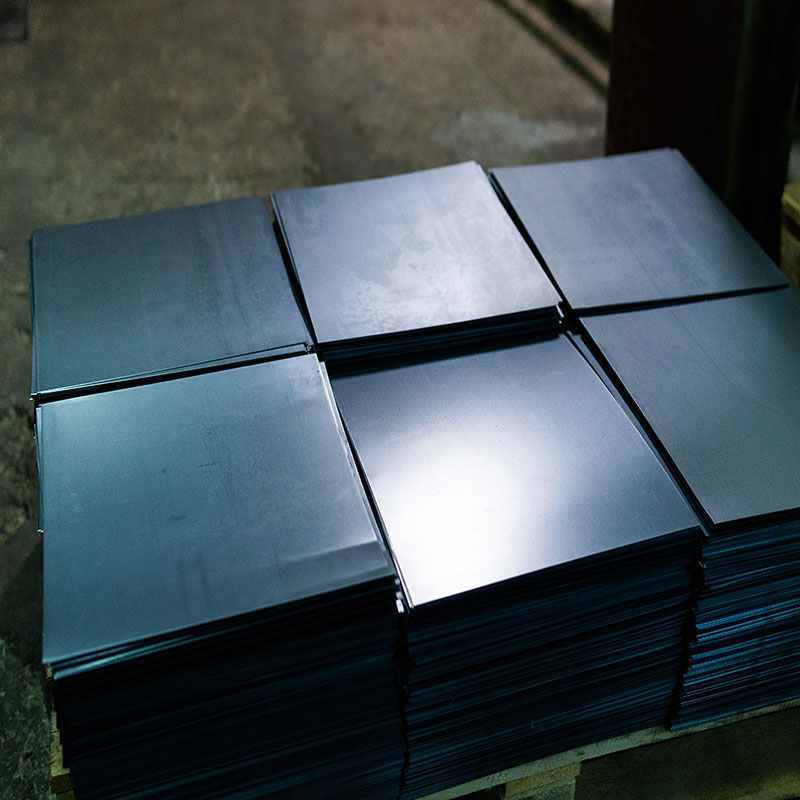

HRP sheet is a type of high-strength steel that is cold-rolled and uncoated. It is frequently used in the production of automotive, white goods, and industrial equipment. Its light weight and durability provide energy savings and reduce costs. With high tensile strength, it offers protection against impacts.

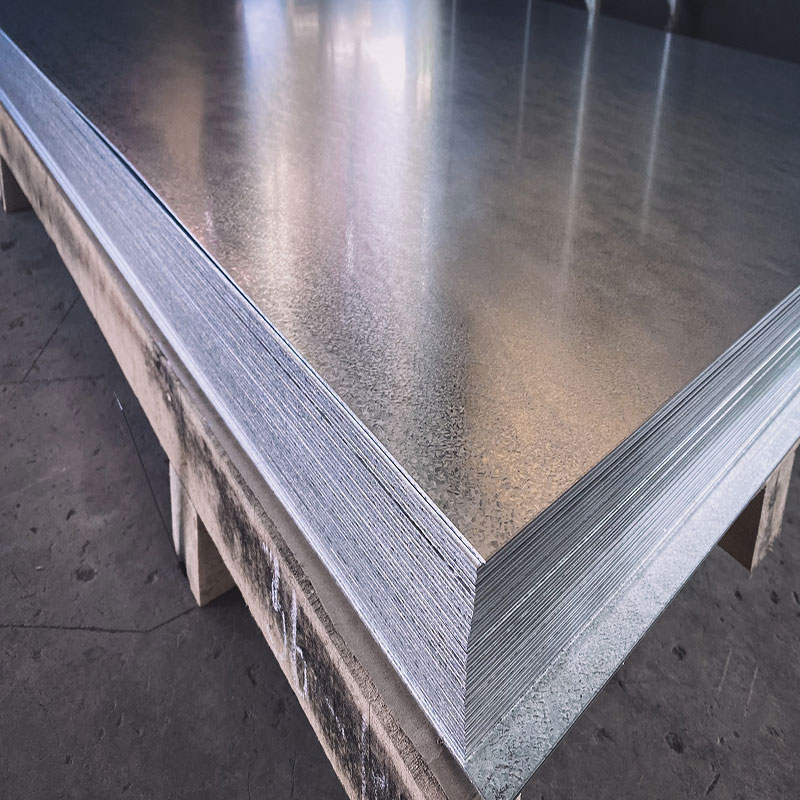

HRP sheet refers to "Hot Rolled Plate" or "Hot Rolled Pickled" sheets, which are one of the flat steel products. HRP sheets, obtained during the production of steel plates from billets through hot rolling and special processes, stand out with their high strength and durability. During the manufacturing process, they are passed through various acid baths to protect the surface, removing oxide and impurities. Therefore, HRP sheets have a smoother and cleaner surface than billet sheets.

HRP sheet grades vary according to the properties of the steel. These grades change based on mechanical properties such as tensile strength, hardness, and flexibility, offering solutions suitable for various industrial needs. The hardness of HRP sheets is a critical factor that affects the material's behavior under load and is chosen according to project requirements.

HRP sheets have a wide range of industrial applications. They are preferred in many sectors, from steel constructions to the automotive industry. Here are the common applications of HRP sheets:

Steel Constructions: Used especially in building and bridge structures, HRP sheets meet the need for durability and high strength.

Automotive Industry: HRP sheets are widely used in the production of vehicle bodies and chassis structures. High-quality HRP sheets provide both lightness and durability in automotive applications.

White Goods Industry: HRP sheets are used in the production of products like washing machines and refrigerators to provide durability and aesthetics.

Pipes and Tanks: The hardness of HRP sheets is a particularly critical factor for structures resistant to high pressure and environmental conditions.

General Engineering Applications: Also used in the production of machine parts and equipment.

Companies selling HRP sheets offer a range of products in different qualities and sizes to meet these wide application areas.

What is the Production Process of HRP Sheets?

The production process of HRP sheets consists of a carefully designed series of steps. Each of these steps highlights the mechanical properties and surface quality of the sheets:

Converting to Slabs: After the steel casting process, semi-finished products known as hot slabs are obtained. These slabs are the primary raw material for HRP sheet production.

Hot Rolling: Sheets are rolled at high temperatures (mostly above 1000 °C) to be thinned and achieve the desired thickness. This stage helps form the inherent mechanical strength of the HRP sheet.

Pickling (Acid Bath): After hot rolling, HRP sheets are cleaned of remaining oxides and residues from their surfaces, resulting in a cleaner surface.

Sizing and Cutting: HRP sheets are cut into different sizes according to customer needs.

Inspection and Packaging: Sheets go through quality control and are carefully packaged before shipment.

In HRP sheet production, optimizing mechanical properties such as hardness, tensile strength, and flexibility ensures a high-quality product.

What Are the Characteristics of HRP Sheets?

HRP sheets have important characteristics that support their industrial uses. These features make them preferable in various application areas:

High Strength: The hardness and tensile strength of HRP sheets provide structural durability. Therefore, they are preferred in steel construction and automotive applications.

Homogeneous Surface Quality: Thanks to the pickling process, the surface becomes clean and smooth, providing an ideal base for painting or coating processes.

Flexibility and Workability: The ability to be processed at high temperatures makes it easy to transform HRP sheets into various forms.

Durability: Their homogenous internal structure ensures long life, able to withstand high temperatures and pressure.

Economic Solutions: Companies selling HRP sheets offer cost-effective solutions in different qualities, contributing to various projects.

These features make HRP sheets useful in various projects.

What Are the Differences Between HRP Sheets and Trapezoidal Sheets?

HRP sheets (Hot Rolled Plate) and trapezoidal sheets are two different types of sheets with distinct characteristics and usage areas. Here are the key differences between them:

1. Production Method

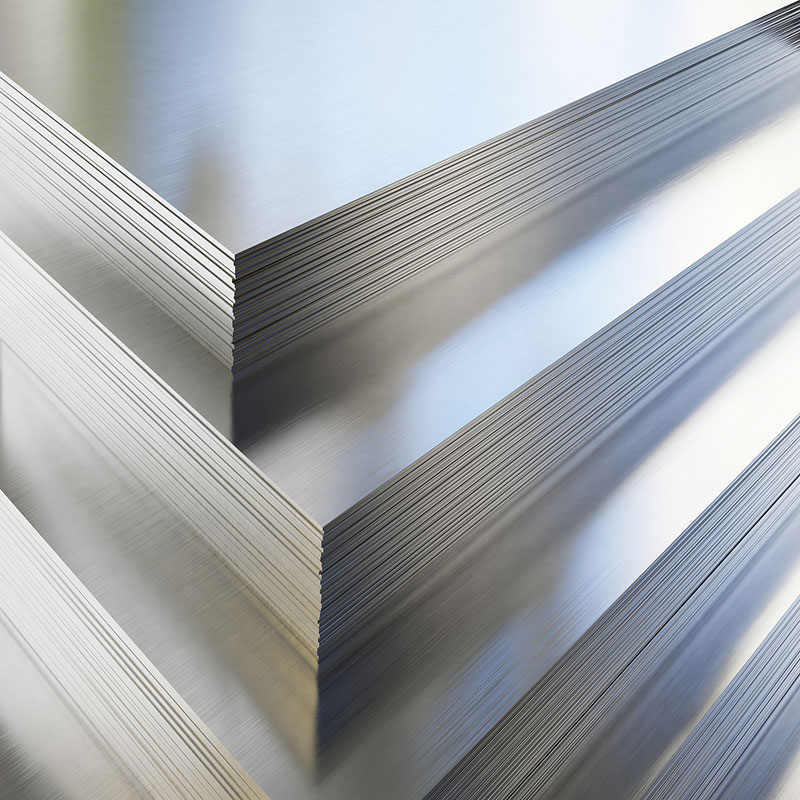

HRP Sheets: These are hot-rolled flat steel sheets, rolled at high temperatures and generally have a thicker and smooth surface.

Trapezoidal Sheets: Cold-rolled sheets often go through galvanizing and painting and are shaped into trapezoids by specialized machines.

2. Surface Structure

HRP Sheets: They have a smooth and flat surface but may experience oxidation and color change as they are mostly unpainted.

Trapezoidal Sheets: They have a wavy, corrugated or trapezoidal surface, shaped for aesthetics and durability.

3. Thickness and Durability

HRP Sheets: Usually thicker and heavier, preferred for projects requiring mechanical strength.

Trapezoidal Sheets: May be thinner but have enhanced durability due to shaping. Their lightness allows for easy installation.

4. Application Areas

HRP Sheets: Used in construction, shipbuilding, pipeline, machinery, and automotive industries, preferred in areas requiring durability like chassis, pipes, and carriers.

Trapezoidal Sheets: Commonly used in roofing, facade cladding, and shelters, preferred in areas seeking light, aesthetic, and economical solutions.

5. Protection and Coating

HRP Sheets: Mostly uncoated, may require anti-corrosion paint or coating.

Trapezoidal Sheets: Usually galvanized and painted making them highly resistant to corrosion.

6. Cost

HRP Sheets: More economical due to thickness and unprocessed state, but costs can increase with added coating and shaping.

Trapezoidal Sheets: Come at a specific cost due to their light and coated surface but save on labor costs in projects due to easy installation.

What Materials Are HRP Sheets Made From?

HRP sheets, a shorthand for "Hot Rolled Plate," refer to hot-rolled steel plates. Common components in steel production include carbon, manganese, silicon, sulfur, and phosphorus. The proportion of these components creates differences among hrp sheet qualities. The raw material of HRP sheets is usually low-carbon steels, which is important for the material's durability and workability.

HRP sheet production involves rolling steel at high temperatures to achieve the desired thickness and dimensions. During this process, the characteristics of the sheet are carefully controlled. HRP sheet hardness is optimized based on the proportions of elements in the steel alloy and production temperature.

What Are the Advantages of Using HRP Sheets?

The primary reasons for preferring HRP sheets are their suitability for various industrial applications. Here are the main advantages of using HRP sheets:

Durability: HRP sheets offer high durability, especially preferred in structural projects. This durability is directly linked to hrp sheet hardness, providing long life.

Easy Workability: Hot-rolled sheets can be shaped more easily compared to cold-rolled sheets. This can be further enhanced by selecting the right material among hrp sheet qualities.

Cost-effectiveness: HRP sheets are widely used for their affordable cost, offering economical solutions in both production and assembly phases.

Wide Application Range: Thanks to their characteristics, HRP sheets can be used in a variety of fields from automotive to shipbuilding, construction to home appliances.

Quality Variety: It's possible to select material suitable for the needs among hrp sheet qualities, providing the most appropriate material for project requirements.

In Which Sectors Are HRP Sheets Preferred?

HRP sheets have a wide range of applications. Here are the main sectors where hrp sheets stand out:

Construction and Building Materials: Due to hrp sheet hardness and durability, they are used in construction projects, preferred in structural components like columns, beams, roofs, and walls.

Automotive Industry: HRP sheets are frequently used in chassis and body parts in automobile production. HRP sheet qualities provide the needed lightness and strength for the sector.

Shipbuilding: Durable and corrosion-resistant materials are important in sea vehicles. HRP sheets are frequently preferred in shipbuilding.

Appliances and Home Devices: Washing machines, refrigerators, and other home appliances use hrp sheets in their internal mechanisms. Their workability and being environmentally friendly are highlighted in this sector.

Machinery and Manufacturing Industry: Features of HRP sheets are effectively used in factory machinery and equipment, providing shaping and assembly solutions in the sector with hrp sheet qualities.

What Are the Durability Features of HRP Sheets?

The durability of HRP sheets refers to their performance against both physical and chemical effects. This durability is directly linked to the components used in the material's design and the production techniques.

Resistance to Climate Conditions: HRP sheets are resistant to rust and corrosion, a great advantage in fields like construction and shipbuilding.

Resistance to High Loads: HRP sheet hardness can withstand very high pressure and tensile forces, increasing its use in steel structures.

Long Life: HRP sheet features offer long-lasting service, which is especially important for cost-effectiveness.

Resistance to Impacts: HRP sheets are resistant to physical impacts and deformations, a preference, especially in the automotive and machinery industries.

What Should HRP Sheet Selling Companies Consider?

HRP sheet selling companies need to consider many factors to ensure customer satisfaction and gain competitive advantage in the sector. Here are the essentials for being successful in this field:

Quality and Standards: Companies should offer a wide range of hrp sheet qualities to meet diverse customer demands. Ensuring product compliance with quality standards is critical for long-term success.

Logistics and Storage: It's important that HRP sheets are not damaged during transportation and storage, and companies should ensure the healthy delivery of products.

Pricing Strategies: HRP sheet selling companies should develop reasonable pricing strategies to balance quality and cost, enhancing customer loyalty.

Technical Support and Consultancy: Companies should provide detailed information on hrp sheet features and usage areas, creating a professional perception with technical support services.

Continuity and Stock Management: Effective stock management and supply chain management enable companies to stand out in the industry.

HRP sheets play a significant role in industrial use due to their durability, versatility, and economic advantages. The features and hardness of HRP sheets offer a wide range of applications in different sectors. Therefore, the points HRP sheet selling companies should consider are critical for gaining competitive advantage in the industry.

TR

TR