Extended hair is a hair extension method that makes hair appear more voluminous, longer, and fuller. Extensions made from natural or synthetic materials are integrated into the existing hair using professional techniques. It offers various options in colors, lengths, and textures to suit the individual's style and needs. It enhances the aesthetic appearance of hair by providing a natural look for daily use.

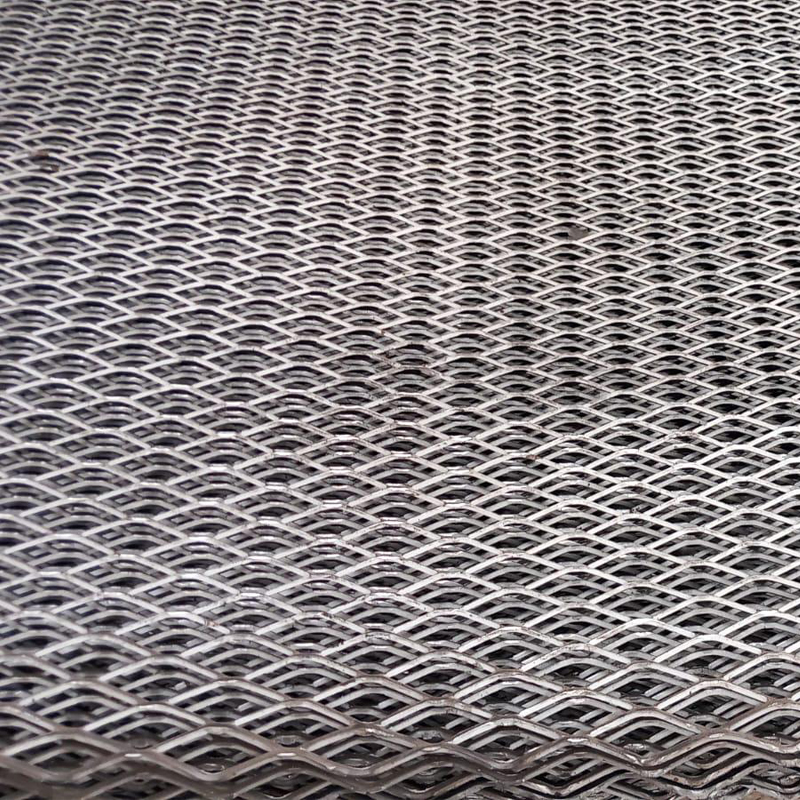

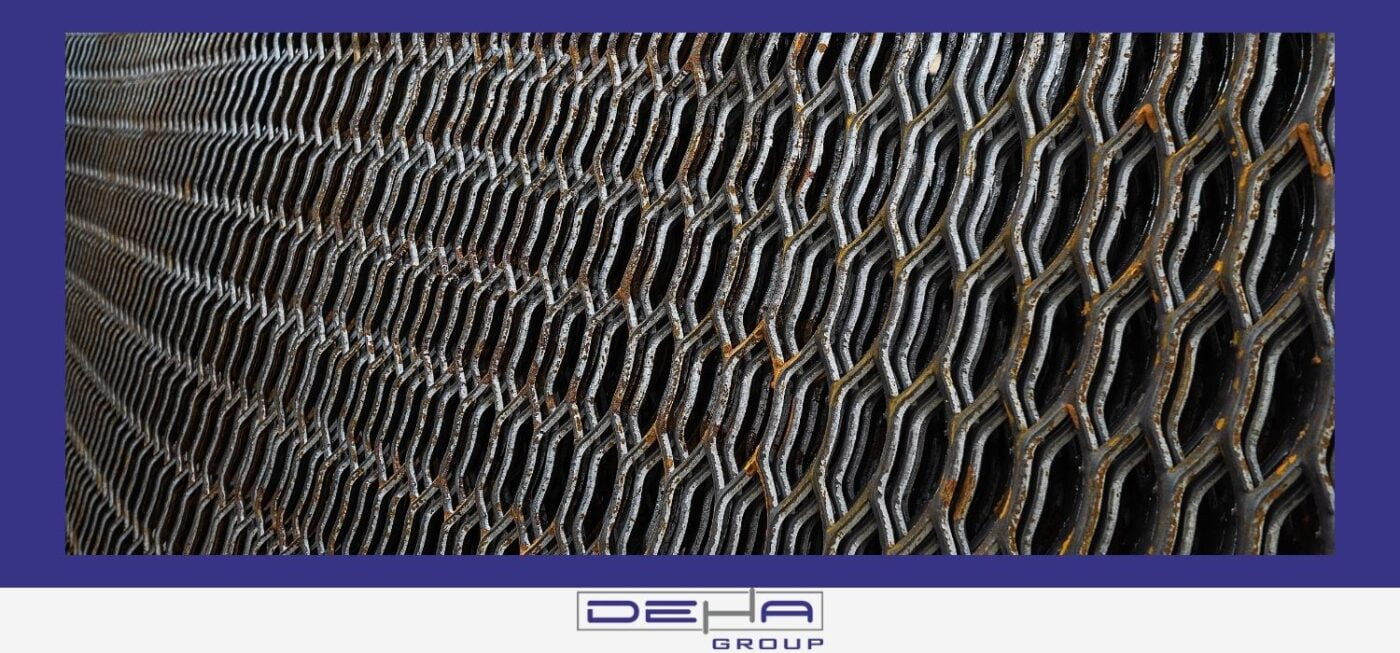

Expanded metal is a material with a special mesh or lattice structure, obtained by cutting and then stretching a metal sheet. This product is widely used across many industries due to its durability and aesthetic appearance. Expanded metal is typically produced from materials such as carbon steel, aluminum, stainless steel, or copper. Since there is no metal loss during the production process, it is both an environmentally friendly and economical choice.

Expanded metal sheet has a wide range of applications and is preferred in many industries. Here are the main areas of use:

Construction Sector

In the construction sector, expanded metal sheet is frequently used in flooring, suspended ceiling systems, stair treads, and facade cladding. It is especially preferred in architectural projects for its aesthetic appeal and durability.

Industry and Manufacturing

Expanded metal sheet is used in machine guards, filters, and ventilation systems. The metal's mesh structure provides both strength and air permeability.

Decoration and Design

Due to its aesthetic appearance, it is used in furniture design, interior decoration, and art projects. It is particularly popular in modern designs.

Transportation and Storage

Expanded metal sheet is preferred in products such as pallets, shelves, and transport baskets. The material's lightweight yet durable nature provides an advantage in these areas.

Security Solutions

It is also used in security products such as fence systems, doors, and windows.

How to Make Expanded Metal?

The fundamental step in expanded metal production is cutting the metal sheet into a specific pattern and then stretching these cuts to form a mesh structure. The process involves the following steps:

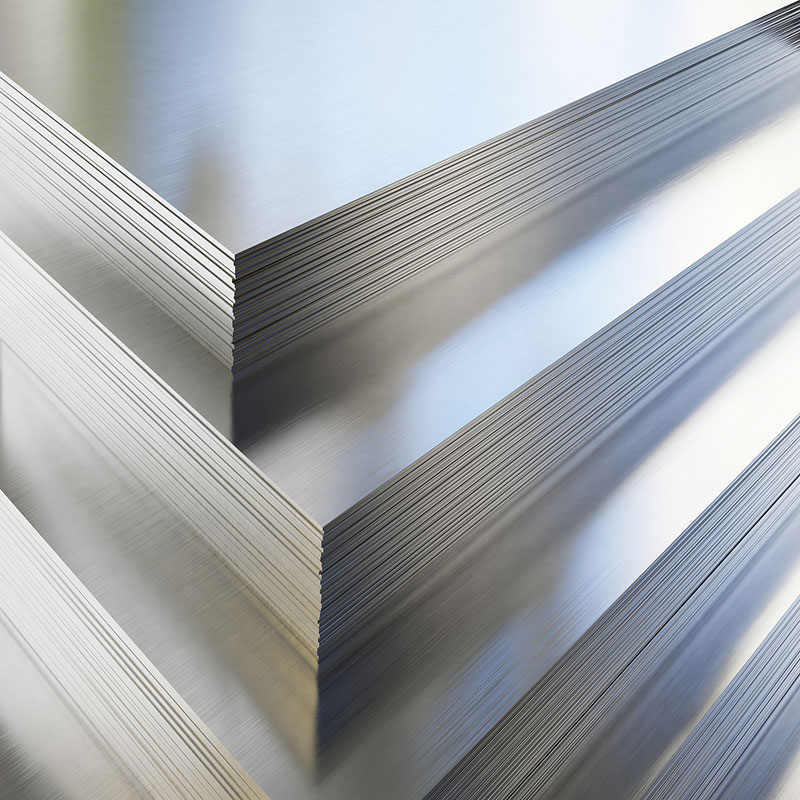

Preparation of the Metal Sheet

A metal sheet of appropriate thickness and dimensions is selected for production. The type of material for the sheet can vary depending on the area of use.

Cutting and Shaping

The metal sheet is subjected to cutting processes in special machines. The cuts are generally made in a parallel and symmetrical pattern. After cutting, the sheet is stretched in special machines to expand it. During this process, the material takes on a mesh shape.

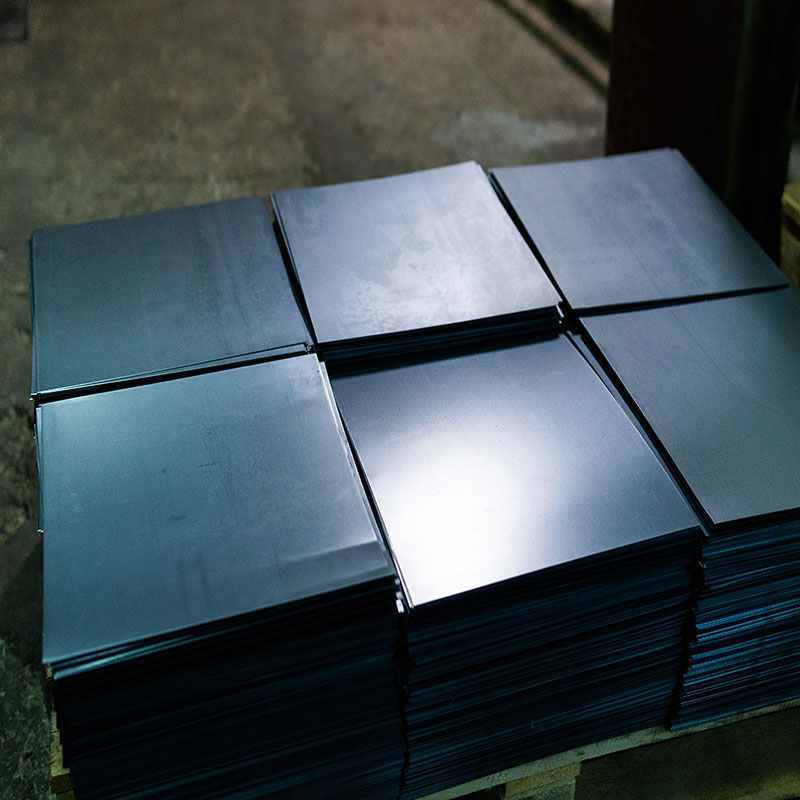

Final Processes

After production, the expanded metal is cut to the required dimensions, and surface treatments are applied. Processes like galvanizing and painting can be applied to add rust resistance, durability, or aesthetic features.

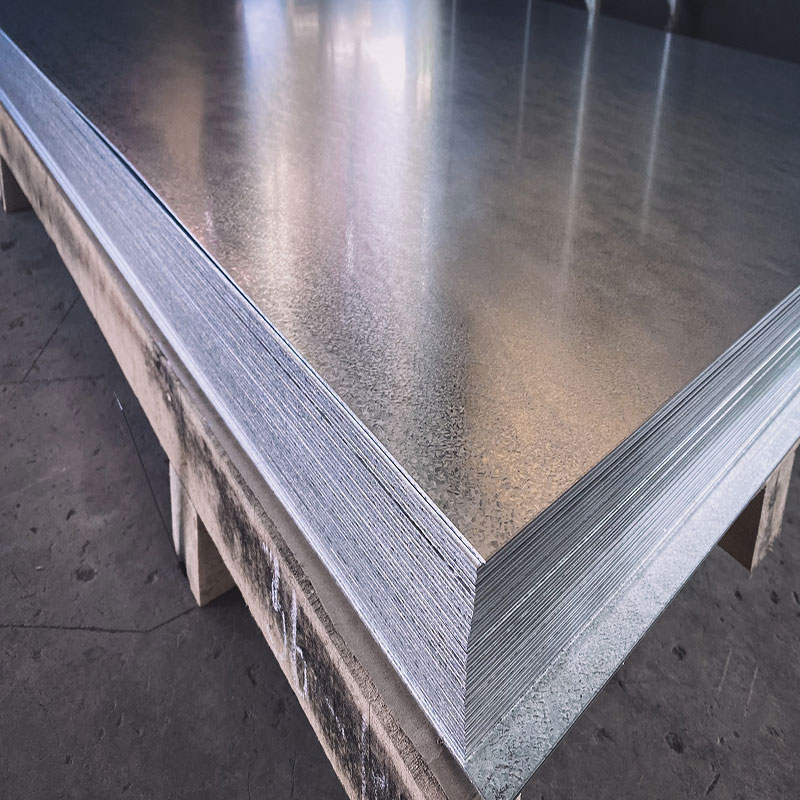

Expanded metal dimensions vary according to the purpose of production and area of use. Standard widths usually range from 1 meter to 2 meters, while lengths can be customized based on demand.

Advantages of Using Expanded Metal

The reasons for the widespread use of expanded metal lie in the advantages it offers:

Durability and Lightness

Expanded metal has a high load-bearing capacity due to its robust structure. At the same time, being a lightweight material makes it easy to install and transport.

Economic and Environment-Friendly

The absence of metal loss during production makes expanded metal both an economic and environmentally friendly option.

Flexibility and Variety

Expanded metal dimensions can be customized according to the intended use, offering a wide range of usage in different sectors.

Aesthetic and Functional

Besides providing a modern and stylish appearance, it allows air and light pass-through. These features make expanded metal an attractive option in architectural projects and decorative applications.

Corrosion Resistance

Expanded metal made from stainless steel or galvanized coatings is resistant to corrosion and is long-lasting.

What are the Features of Expanded Metal?

Expanded metal is a durable and lightweight material formed by cutting and stretching metal sheets into a specific pattern. This special production technique enhances the physical durability of the sheet while providing lightness, an aesthetic appearance, and functionality. Due to its perforated and gridded design, expanded metal is frequently preferred in various sectors. It is especially used in industrial and architectural projects for decorative and technical purposes.

The main features of expanded metal include durability, long-term usage, lightness, aesthetic design, and air and light permeability. This type of sheet can be safely used in structures carrying heavy loads due to its high strength. Additionally, the surface design provides advantages such as sound insulation and heat distribution.

What are the Dimensions of Expanded Metal?

Expanded metal dimensions can vary depending on the project's needs and area of use. Generally, expanded metals can be produced in standard sizes or in special dimensions according to customer requests. The dimensions of the openings (mesh spacing), the thickness of the sheet, and the general dimensions of the plate form the basis of these measurements.

Standard expanded metal dimensions can be listed as follows:

Sheet Thickness: Production can start from 0.5 mm up to 5 mm or thicker.

Mesh Openings: Can be in different sizes like 10x25 mm, 15x30 mm, 20x40 mm. These openings can be customized according to the purpose of use.

Sheet Dimensions: Usually produced in standard sizes like 1000x2000 mm, 1250x2500 mm, and 1500x3000 mm.

Expanded metal dimensions can be customized for use in the construction sector for carrier systems, decorative designs, or ventilation systems.

Materials Used in Expanded Metal Production

The materials used in expanded metal production can vary depending on the area of use and the project. The most common materials are:

Carbon Steel: The most preferred material due to its durability and economic nature. It is frequently used in industrial projects.

Stainless Steel: Known for its corrosion resistance. Preferred in outdoor applications and areas requiring hygiene.

Aluminum: Used in portable structures and decorative applications as a lightweight and durable material.

Copper and Brass: Preferred for decorative designs. Also offers an aesthetic appearance.

These materials are chosen to enhance the durability, longevity, and aesthetic features of expanded metal.

Coating and Surface Treatments of Expanded Metal

Expanded metal can be made more durable with various coatings and surface treatments after production. These processes ensure the metal's protection against corrosion, enhance its aesthetic appearance, and prolong its service life. The most common surface treatments and coatings include:

Galvanizing: Provides protection against corrosion. Ideal for outdoor use.

Electrostatic Powder Coating: Offers different color options for decorative purposes. Also protects the sheet surface against external influences.

Anodizing: Used especially on aluminum sheets. Increases surface brightness and provides protection against scratches.

Passivation: A method preferred for stainless steel. Enhances the chemical resistance of the sheet.

Coating and surface treatments enhance both the aesthetic and functional properties of expanded metal, creating a wide range of applications in various projects.

Challenges in Using Expanded Metal

One of the most common challenges in using expanded metal is the flexibility requirements related to expanded metal dimensions. Different projects may require sheets in different sizes, and production can become complex when going beyond standard sizes. Additionally, due to the perforated structure of the material, there may be a decrease in strength and losses in precision during cutting in some cases.

In installation processes, issues like vibration resistance can be encountered due to the light and perforated structure of expanded metal. Especially for outdoor applications, selecting appropriate coating techniques to enhance corrosion resistance becomes mandatory.

Efficiency in Expanded Metal Production

Optimizing production processes is of great importance to increase efficiency. Advanced laser cutting and shaping technologies can increase production speed while reducing error rates. Additionally, the quality of raw materials used in expanded metal production directly affects efficiency. The use of high-quality steel or aluminum allows for the production of more durable and long-lasting products.

To reduce energy consumption and provide environmentally friendly production, automation systems can be utilized in modern facilities. These systems increase both production speed and reduce labor costs.

Using Next-Generation Materials in Expanded Metal

Next-generation materials are shaping the future of expanded metal. Especially carbon fiber-reinforced materials and composites increase the strength of the metal while reducing its weight. This proliferates the use of expanded metal in sectors such as automotive and aviation, where weight is critically important.

Moreover, solutions developed with nanotechnology in surface coatings enhance the corrosion resistance and aesthetic appearance of the metal. Regarding expanded metal dimensions, next-generation materials make it possible to produce across a wider range. Especially thin-section yet high-strength materials provide design and application flexibility.

TR

TR