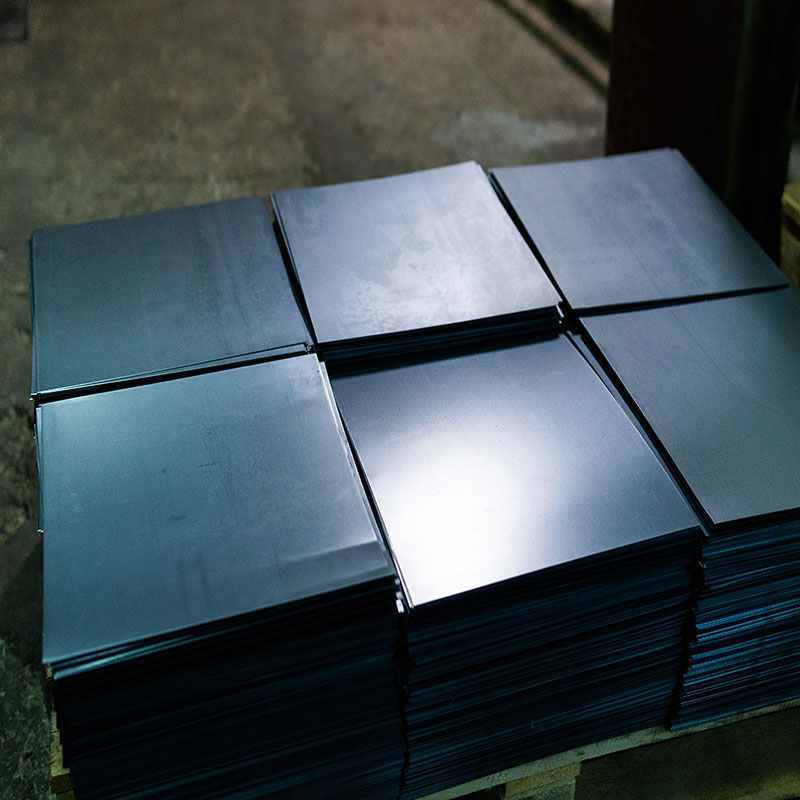

Black sheet metal is one of the most preferred materials in the metal industry due to its durability and versatile use. With its flat and smooth surface, black sheets have an aesthetic appearance and are commonly used in construction, automotive, furniture, and industrial applications. These sheets, obtained through hot rolling during the production process, offer high strength and ease of processing. As a quality and cost-effective option, black sheet metal provides long-lasting solutions for your projects.

Black sheets are a material frequently used in the metal industry and preferred in many industrial fields, known for being durable and practical. Black sheet is known as hot-rolled steel sheet and is made from carbon steel. It gets its name from the dark gray or black oxide layer on its surface. This oxide layer forms on the surface of the steel during the production process, giving it a black appearance. Black sheets are usually offered in round, flat, or coil shapes and can be produced in different thicknesses.

The production process of black sheet metal is quite detailed and requires careful handling. Here's the step-by-step production phase of black sheet metal:

- Raw Material Selection: The raw material for black sheet metal is typically carbon steel. This steel has a structure that is workable and formable.

- Heating: The raw materials are heated at high temperatures to soften them. This process usually takes place above 1200 degrees Celsius.

- Rolling: The hot steel is passed through rollers to be rolled into thin sheets. At this stage, the steel is covered with an oxide layer that causes a black surface to form.

- Cutting and Shaping: The black sheets, which are turned into coils or flat plates according to needs, are cut to specific dimensions and prepared for shipment.

In Which Areas Are Black Sheets Used the Most?

Black sheets are widely used in various industrial and commercial areas. The following are the fields where black sheets are most preferred:

Construction Sector: Black sheets are used in building and bridge structures, steel constructions, columns, and beam structures. Thanks to the durability of steel, these structures are very long-lasting.

Automotive Sector: Black sheets are preferred in the production of vehicle chassis, chassis parts, and bodywork. As the sheet is produced in black tones, its durability is especially prioritized.

Machine and Equipment Manufacturing: Black sheets are used in the production of various industrial machines, equipment bodies, and structural parts.

Shipyard and Shipbuilding: The durable structure of black sheets is important in ship construction and shipyards. They are specially preferred for their ability to withstand marine environments.

Fence and Panel Systems: Black sheets are also used in the production of fence systems and industrial panels.

Storage Tanks and Silos: In large-scale production and storage structures, the strength of black sheets stands out.

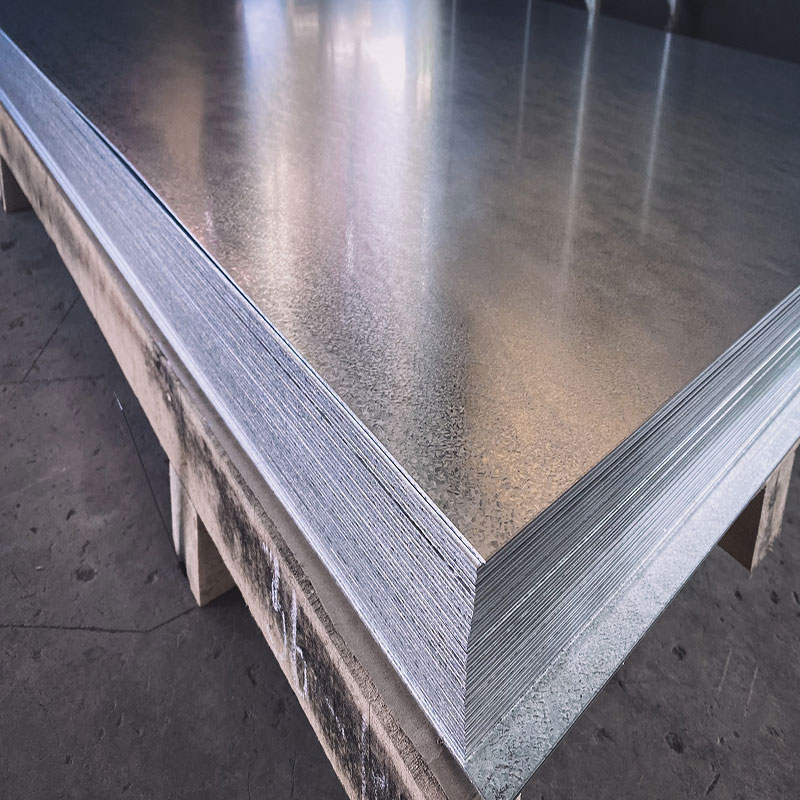

What are the Differences Between Black Sheets and Galvanized Sheets?

There are significant differences between black sheets and galvanized sheets. These differences can be summarized as follows according to their areas of use and properties:

- Coating Difference: Black sheets do not have any coating. However, galvanized sheets are obtained by coating the surface of the steel with zinc, making them resistant to rust.

- Durability: Although black sheets are durable, they are not as resistant to rust as galvanized sheets. Galvanized sheets are a more suitable option for humid and outdoor environments.

- Aesthetics: Black sheets have a black color and a matte surface. Galvanized sheets have a shiny and more decorative appearance thanks to their zinc coating.

- Cost: Black sheets are more economical compared to galvanized sheets. However, the long-lasting nature of galvanized sheets can offset the cost difference.

What are the Properties of Black Sheets?

The notable properties of black sheets can be listed as follows:

- Strength: Black sheets are used in various structural applications due to their high durability.

- Flexibility: Thanks to their rolled structure, they can easily be transformed into various shapes.

- Economical: The production of black sheets is more cost-effective compared to other coated sheets.

- Widespread Use: Their preference in many sectors shows that black sheets are versatile.

- Workability: Black sheets are suitable materials for welding and cutting processes.

Black sheets offer versatile solutions in industrial and commercial areas. Knowing the differences between black sheets and galvanized sheets will help you select the material that suits your needs. With their strength, flexibility, and economical nature, the usage areas of black sheets continue to expand.

Advantages and Disadvantages of Black Sheets

Black sheets are one of the fundamental materials of the steel industry and are widely used in many sectors. The advantages and disadvantages of black sheets play an important role in their selection and areas of use.

Advantages

- High Durability: Black sheets have high mechanical durability, allowing them to be used comfortably in heavy industries.

- Easy Workability: Black sheets have advantages such as easy shaping and diversification in the production process.

- Economical: They are more affordable compared to other steel types, providing a cost-effective solution.

- Versatility: Since they can be produced in different sizes and thicknesses, they can be used in a wide variety of areas.

Disadvantages

- Corrosion Risk: Black sheets have low resistance to corrosion. Therefore, if they are to be used outdoors, they must be protected with appropriate coating.

- Weight: They may be heavier compared to other materials, which can be a disadvantage in some applications.

- Aesthetic Disadvantages: Black sheets do not have a shiny or aesthetic surface like stainless steel, limiting their use in decorative applications.

In Which Industrial Fields Are Black Sheets Preferred?

Black sheets are used in various industrial branches thanks to their versatile and durable nature.

- Automotive Sector: Preferred in the production of vehicle chassis and frames.

- Construction and Building: Used in building frameworks, roofing systems, and support elements of reinforced concrete structures.

- Machine Industry: Frequently used in the production of agricultural machines, industrial equipment, and production line parts.

- Shipyard and Shipbuilding: Used in the production of ship hulls and structural elements.

- Energy Sector: Can be used in pipelines, power plants, and wind turbines.

Can Black Sheets Be Painted?

Yes, black sheets can be painted. However, it is essential to prepare the surface carefully before the painting process. The following steps are important in the painting process:

- Surface Cleaning: The surface of the black sheet should be freed from substances like oil, dirt, and rust. Chemical cleaners or sandblasting can be used for this.

- Applying Primer: It is recommended to use a suitable primer to enhance paint adhesion.

- Paint Selection: Paint types suitable for metal surfaces should be chosen for black sheets.

- Painting and Drying: After painting evenly, an appropriate drying time should be awaited.

The painting process enhances the aesthetic and protective properties of black sheets. Therefore, it is an ideal option for those who wish to increase their resistance to rust.

What Should Companies Selling Black Sheets Pay Attention To?

Companies trading in black sheets need to pay attention to certain criteria to succeed:

- Material Quality: It is important to ensure the quality of the black sheets being sold. Low-quality materials can lead to customer dissatisfaction.

- Stock Management: Adequate stock should be maintained to meet customer demands and deliveries should be made on time.

- Price Competition: Offering competitive prices in the black sheet market is a critical factor for attracting potential customers.

- After-Sales Support: Providing technical support and information to customers after sales is important for establishing long-term business relationships.

- Logistics Organization: A seamless logistics plan should be implemented for the transport and delivery of black sheets.

What Materials Are Used in the Production Process of Black Sheets?

The production of black sheets primarily uses the following materials and processes:

- Iron and Carbon: The basic components of black sheets are iron and carbon. The amount of carbon affects the durability and flexibility of the sheet.

- Weight-Enhancing Alloys: Some black sheets use alloys such as manganese and silicon to enhance their properties.

- Heating and Cooling: Production is done at high temperatures and cooled with specific temperature control.

- Valves and Rollers: Various machines and rollers are used in shaping black sheets.

These materials and processes ensure that black sheets are a durable, cost-effective, and versatile steel material.

What are the Differences Between Black Sheets and Stainless Steel?

Black sheets and stainless steel have different areas of use and properties. The essential differences between these two materials can be listed as follows:

- Corrosion Resistance:

- Black sheets: More sensitive to corrosion and require protective coating.

- Stainless steel: Resistant to corrosion and does not require additional coating in most outdoor environments.

- Price:

- Black sheets: More economical.

- Stainless steel: More expensive material.

- Aesthetics:

- Black sheets: Have a matte surface and are limited in decorative applications.

- Stainless steel: Have a shiny and aesthetic surface.

- Usage Areas:

- Black sheets: Ideal for industrial applications and structures requiring durability.

- Stainless steel: Preferred in kitchenware, medical devices, and decorative applications.

Black sheets and stainless steel differences facilitate the correct material selection according to needs. Black sheets hold an indispensable place in the industrial world as an economical and versatile material and can offer a lot with proper processing and protection techniques.