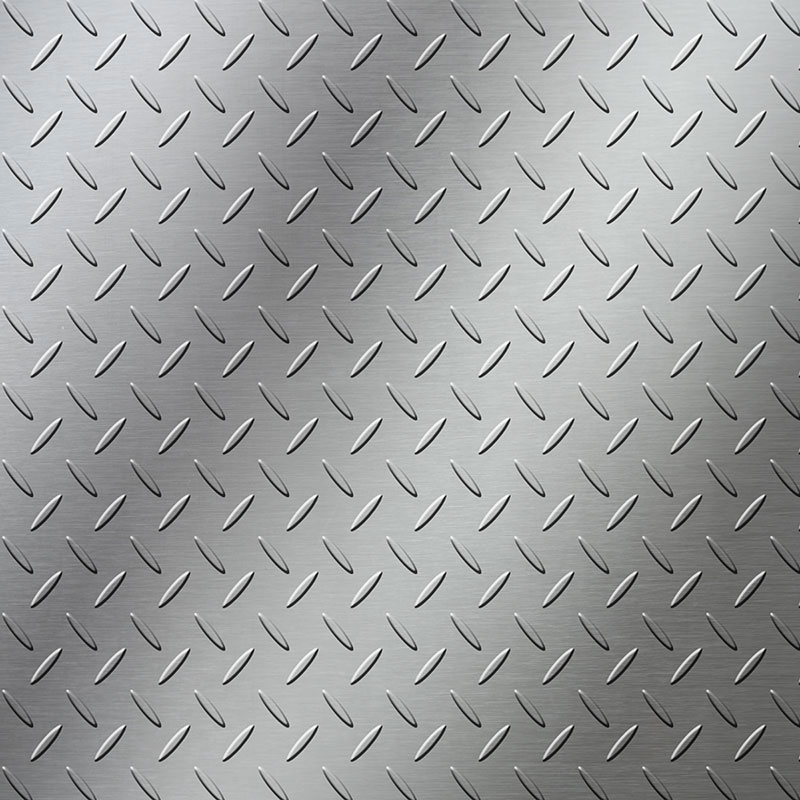

Baclavate sheets are types of perforated metal sheets that offer durability and aesthetic appearance. They are mostly preferred in flooring, stair treads, and platforms due to their non-slip surface feature. They are manufactured from stainless steel, aluminum, or galvanized materials, and have a long-lasting and sturdy structure. They have a wide range of applications from industrial areas to decorative projects.

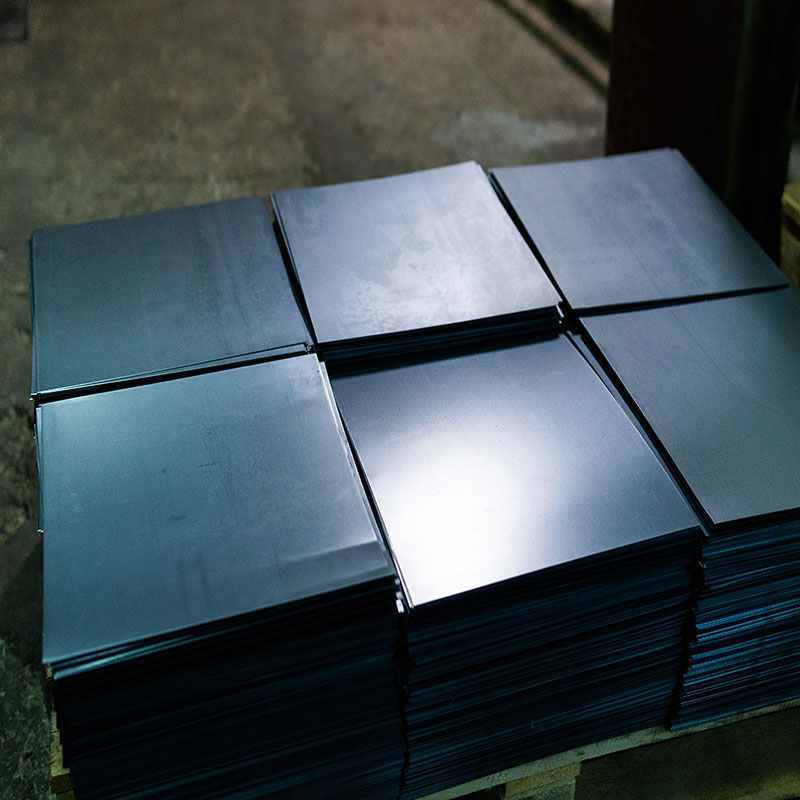

Chequered steel plates are a special type of metal sheet with embossed surfaces in a diamond pattern. This design offers both an aesthetic appearance and functional advantages. Thanks to the diamond pattern, these plates have non-slip surfaces, making them prominent in various application areas.

The prominent features of embossed sheets are as follows:

- Non-Slip Surface: Thanks to its diamond patterns, it reduces the risk of slipping in walking and movement areas.

- Durability: It is long-lasting against various environmental conditions.

- Aesthetic Design: Offers a modern and professional appearance.

- Easy Cleaning: It has a low likelihood of retaining dirt and oil.

- Lightweight: Produced in different thicknesses as needed, its lightweight structure provides an advantage in transport and installation.

Where Are Checker Plates Used?

Checker plates are used in various areas thanks to their anti-slip surface advantage:

Industrial Floors: Preferred in factories and production facilities to reduce slip risks.

Vehicle Bases: Provides a non-slip surface in commercial and industrial vehicle floors.

Stair Treads: Ideal for preventing accidents caused by slippery surfaces.

Walkways: Creates safe walking surfaces in warehouses and logistics centers.

Decoration: Can be used in both interior and exterior decoration projects for an aesthetic appearance.

What Materials Are Checker Plates Made From?

Checker plates are typically made from the following materials:

- Carbon Steel: Common due to its durability and cost-effectiveness.

- Stainless Steel: Preferred in humid and corrosion-prone environments.

- Aluminum: Used for its lightweight and corrosion resistance.

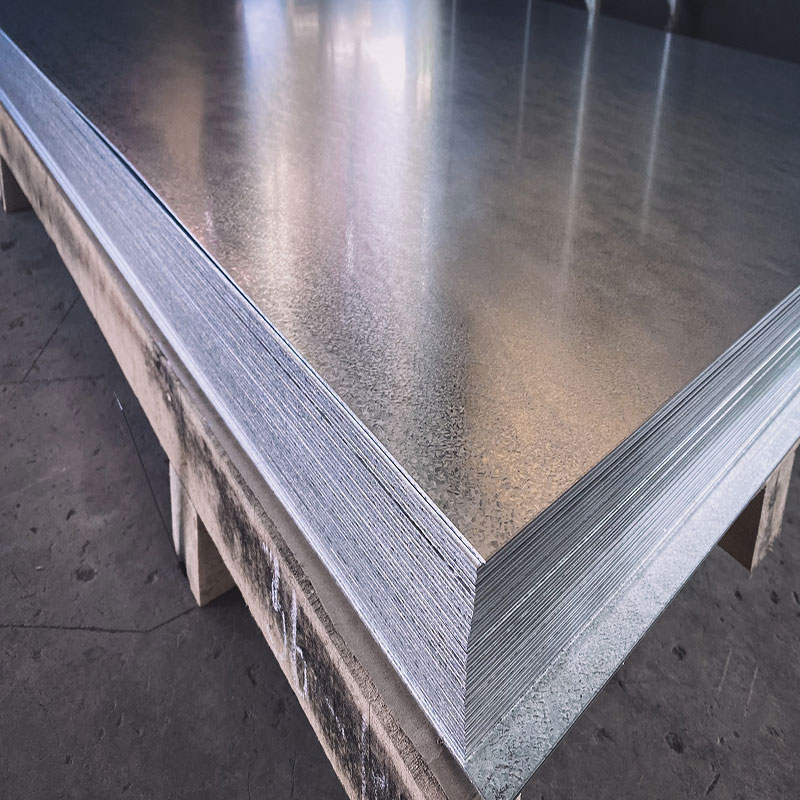

- Galvanized Steel: Protected with a special coating against corrosion.

How Is the Durability of Checker Plates Tested?

Checker plates are among the durable and reliable materials used in construction, industrial, and automotive sectors. They are particularly preferred in flooring and platform applications due to their anti-slip surface structure. Understanding the durability of these plates is important for ensuring long-lasting and safe use. So, how is the durability of checker plates tested? Here are the key points to consider in this regard:

1. Material Quality and Production Standards

Before starting the durability test of checker plates, it's important to know the standards the material is produced in accordance with. Plates produced in compliance with international standards such as ISO and EN generally offer higher strength. The quality certificates provided by the manufacturer should also be evaluated.

2. Tensile Test

The tensile test is a method used to measure the strength of checker plates. This test determines how much load the material can withstand. By measuring the elastic limit and breaking point with the tensile force applied on the plate, the level of durability is analyzed.

3. Abrasion Test

Checker plates are constantly exposed to pedestrian or vehicle traffic. Therefore, special tests are conducted to measure abrasion resistance. The slip and abrasion rates of the surface are important indicators to understand the plate's performance in long-term use.

4. Impact Resistance Test

Considering the use of checker plates in areas with heavy loads, testing their resistance to impacts is a critical issue. This test evaluates whether there is any deformation on the surface after the plate is exposed to impacts.

5. Corrosion Resistance Test

Checker plates are often used in open spaces or humid environments. Therefore, their resistance to rust should be tested. The corrosion resistance test is an important step to ensure long service life of the plate.

6. Surface Inspection

In addition to durability tests, the surface structure of checker plates should also be inspected. The smoothness and flawlessness of the surface affect the load-bearing capacity of the plate. The sharpness and uniformity of the checkered pattern are determining factors in terms of durability.

What Is the Function of the Surface Structure of Checker Plates?

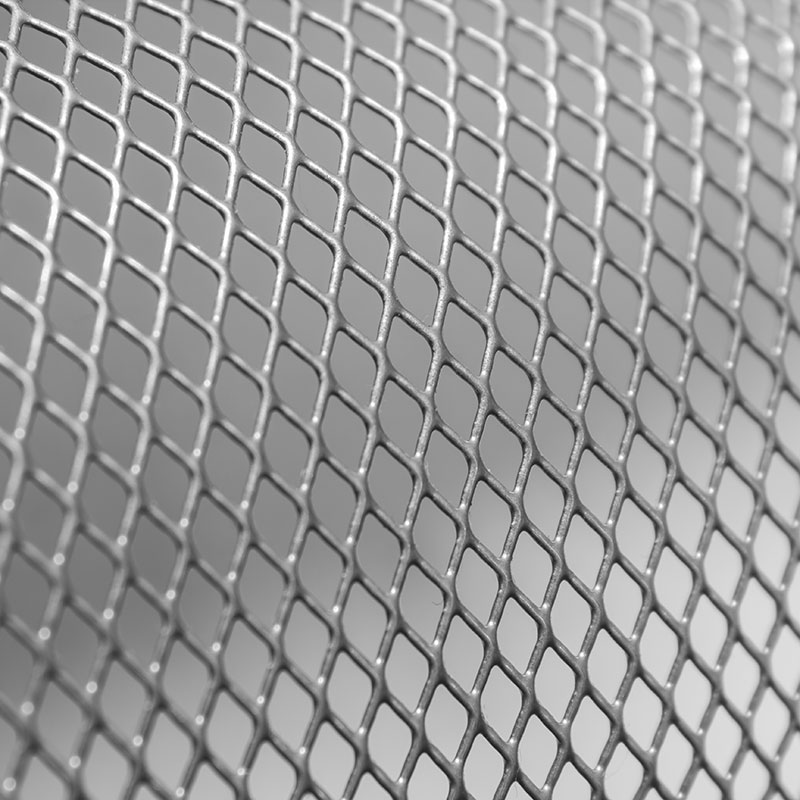

Checker plates are metal products with a patterned surface that attract attention and are used for different purposes in many industries. The surface structure of these plates not only provides an aesthetic appearance but also offers functional benefits. Understanding the main advantages and usage areas of the surface structure of checker plates reveals why these materials are so popular.

Anti-Slip Surface Advantage

One of the most known features of checker plates is that they offer an anti-slip surface. This feature provides great safety especially in wet or inclined areas. They are commonly used in construction, industrial platforms, ramps, and stairs. Thanks to the checker pattern on the surface, shoes or vehicle tires adhere better to the surface, minimizing the risk of slipping.

Durability and Longevity

Checker plates are generally made from durable metals and are resistant to external effects. With processes like galvanizing, they can become even more resistant to corrosion. This feature offers long-lasting performance in outdoor use or areas carrying heavy loads. The checkered surface structure enhances the material's strength, creating a more robust structure.

Aesthetic and Practical Use

Checker plates are also preferred for their aesthetic appearance as much as for their functionality. This patterned structure provides a modern look, especially in decorative projects. Additionally, the surface's easy cleanability makes it preferred in areas requiring hygiene.

Usage Areas in Various Industries

The surface structure of checker plates offers functionality in a wide range of industries. Vehicle floor coverings, factory floors, elevator interiors, and ship decks are examples of these usage areas. They are also frequently preferred to increase safety in machine bases in production areas and in storage areas.

The surface structure of checker plates offers significant advantages in terms of safety and aesthetics. With their anti-slip surface, durability, and wide range of applications, these plates have become an indispensable material in many industries. If you are looking for a safe, durable, and functional solution, checker plates can provide an ideal answer to your needs.

How Are Checker Plates Manufactured?

The production process of checker plates generally involves the following steps:

- Material Selection: The type of metal to be used is determined.

- Cutting: Plates are cut to the required sizes.

- Pattern Formation: Checker patterns are shaped on the plate surface by special machines.

- Coating: Galvanizing or painting processes are applied if necessary.

- Quality Control: Quality tests are conducted after final production.

In Which Sectors Are Checker Plates Used?

Checker plates are widely used in the following sectors:

- Industry: Used in factory floors, walkways, and machinery.

- Transportation: Preferred in truck and trailer floors.

- Building and Construction: Used in stairs, ramps, and decorative applications.

- Marine: Ideal for non-slip surfaces in ships and boats.

- Automotive: Used in vehicle floor and loading areas.

What Standards Are Checker Plates Produced According To?

Checker plates are produced in compliance with national and international standards. Standards such as EN, ASTM, and ISO guarantee quality and durability during the production process. These standards measure the plates' resistance and reliability under various conditions.

How Do Checker Plates Differ From Other Types of Plates?

Checker plates differ from other types of plates with the following features:

- Anti-Slip Surface: Offers a safer surface compared to standard plates.

- Aesthetic Appearance: Preferred for its design in decorative projects.

- Application Area: Used more widely in different sectors due to its advantages.

Checker plates offer versatile solutions in many sectors in terms of both safety and aesthetics. With their production technology and material quality, these plates play an indispensable role in everyday life and industrial areas.